集装箱焊缝的开放式数控自动专用焊机设计(开题报告,答辩ppt,论文说明书18800字,cad图纸,焊机演示avi)

摘要

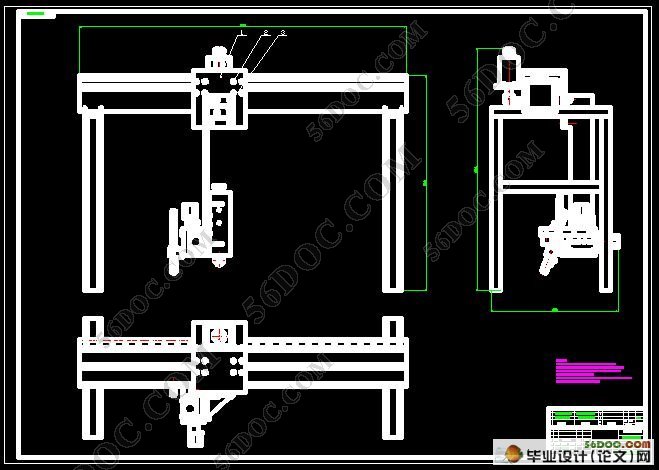

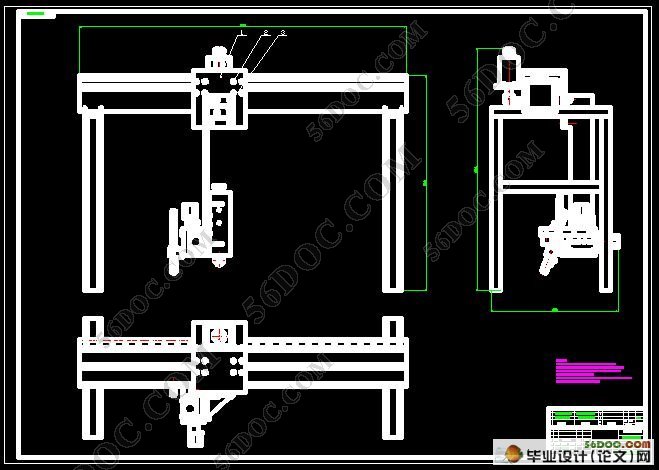

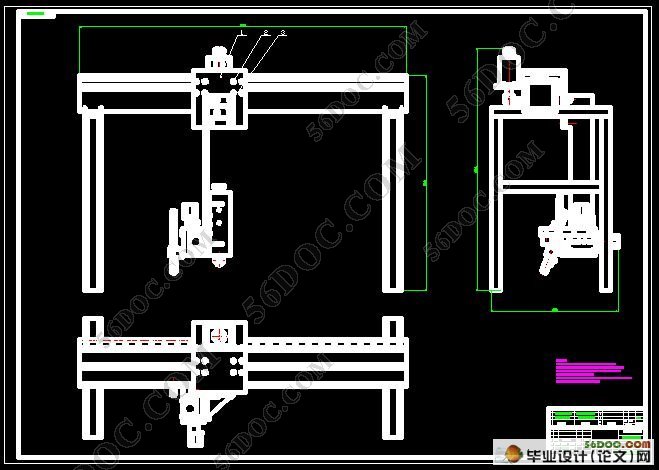

在调研了深圳南方中集东部物流装备制造有限公司的集装箱焊接现状后,设计能自动焊接长约12米的集装箱顶板与顶横梁焊缝的开放式数控自动专用焊机,并做出样机进行试验。

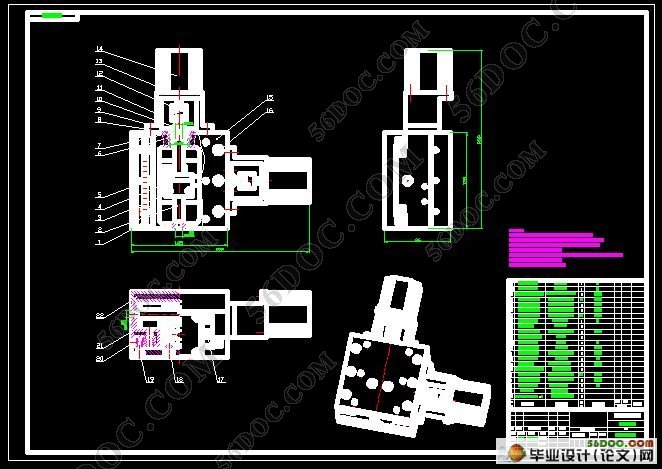

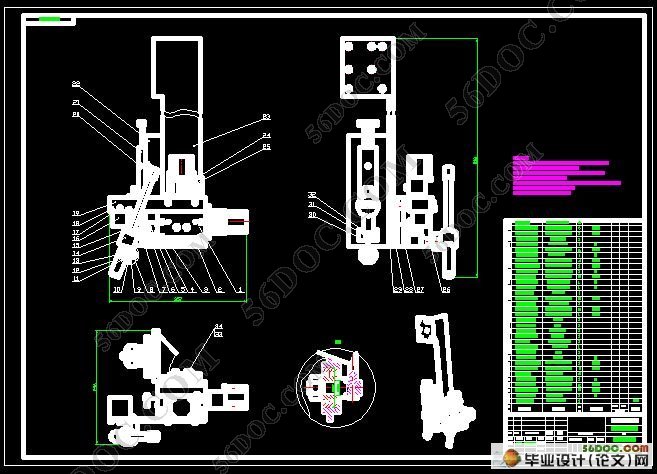

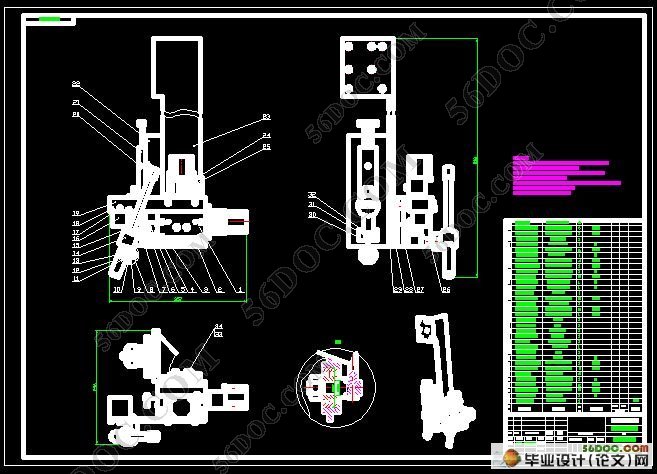

该设备工作方式:系统通过摄像头对焊缝进行跟踪拍摄,经过信号筛选,记录焊缝水平方向的轨迹;并使用自带信号输出接口的数字百分表对焊缝竖直高度进行测量。同时使用编码器记录水平和竖直数值的相对位置,从而模拟出焊缝的空间位置,通过脉冲信号驱动水平和竖直方向的两个步进电机,使焊枪准确找到焊缝,以便完成自动焊接任务。这可大大降低工人的劳动强度,提高焊接自动化程度。

在本课题研制过程中,完成了整个集装箱自动焊机机械部分的设计计算、零件的加工和样机的装配工作。在类似的数控焊机设计中,首次提出使用数字百分表测量焊缝的竖直高度,测量简单方便。

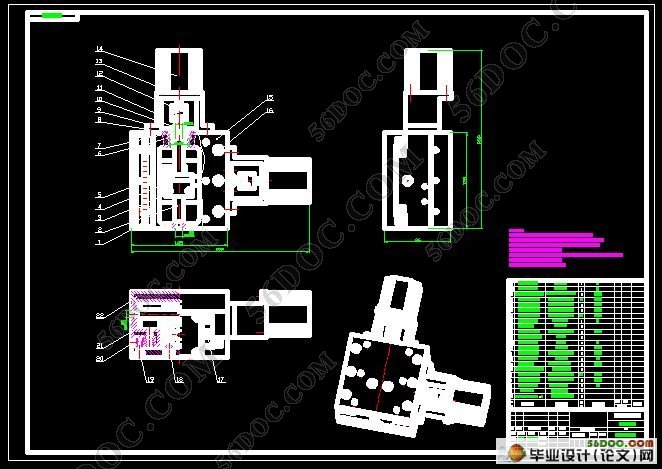

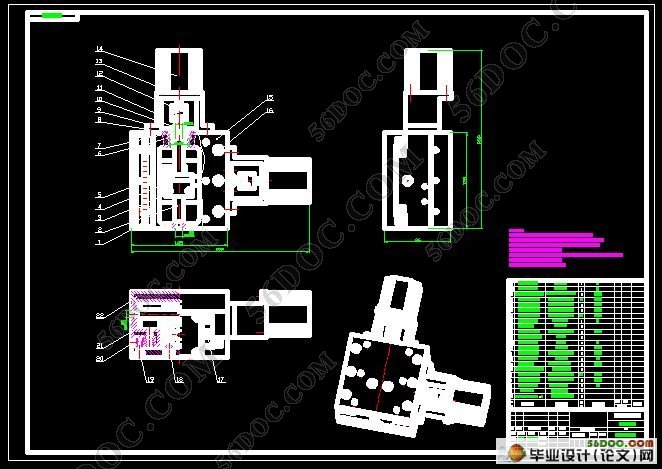

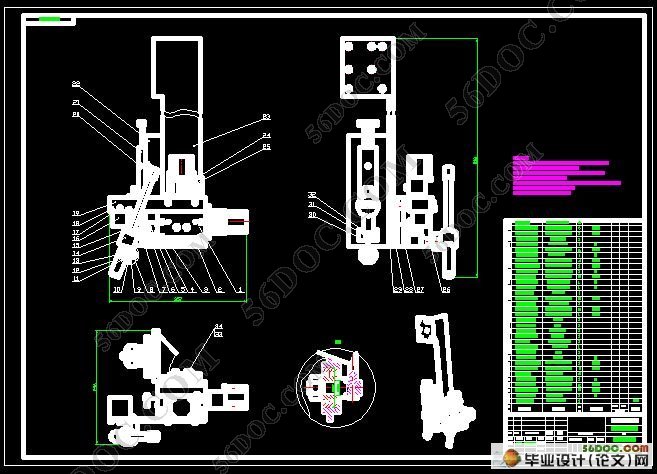

机械结构设计包括传动方案的确定与选择、滚珠丝杠副的选择、滚动导轨副的计算与选择、步进电机的选择、联轴器的选择、接近传感器的选择、气缸的选择等。

关键词:集装箱、焊接、工业控制、数控技术

Abstract

In the study of the Shenzhen southern China CIMC eastern logistics equipment Manufacturing Co.,Ltd.After visit the status of the container welding, automatic welding design is about 12 meters of container roof beams and the top seam of open CNC automatic special welding machine, and make a prototype.

The device works: the system through the camera tracking shot of the weld, after the signal filter, recording horizontal direction of the track to weld; and use its own digital signal output interface of the weld dial indicator to measure vertical height. At the same time, encoder record levels and the relative vertical position value in order to simulate the spatial location of the weld, through the pulse signal to drive the stepper motors of level and vertical direction to find the weld exact and complete the automatic welding. This can greatly reduce the labor intensity and improve the level of welding automation.

Developed in the course of this project, the completion of the entire container auto-welding machine design and calculation of the mechanical parts, spare parts processing and assembly of prototype work. CNC machine in a similar design, first proposed the use of digital dial indicator measuring the vertical seam height measurement is simple and convenient.

Mechanical structure design, including the determination of transmission and choice, the choice of ball screw, scroll Guide calculation and choice, the choice of stepper motor, the choice of coupling, the choice of proximity sensors, the choice of cylinder.

Key words: container, welding, industrial control,CNC Technology

设计原始参数

本次毕业设计题目是:某厂集装箱焊缝的开放式数控自动专用焊机。主要用来完成集装箱顶板和顶横梁焊接工作,其速度、精度要求不高。参数如下:

行程: X方向 50mm

Y方向 50mm

Z方向 12000mm

快速进给速度:1.5m/min

Z传动方式: 齿轮齿条

X、Y传动方式:步进电机直联

|