中文译文

叶片泵磨损理论和实践方面(中文4600字,英文3100字)

第二部分:关于维克斯公司叶片泵实验磨损情况分析

A. Kunza,R.Gellrichb,G.Beckmannc,E.Broszeita

a材料科学研究所,达姆城工业大学,P.O.Box 11 14 52,64229 达姆城,德国

b齐陶

摘要

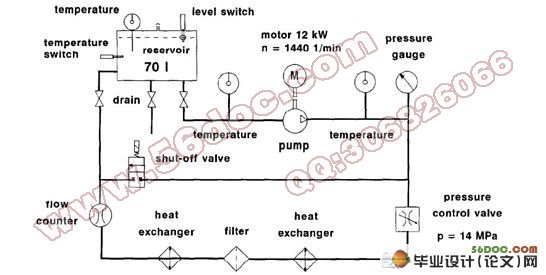

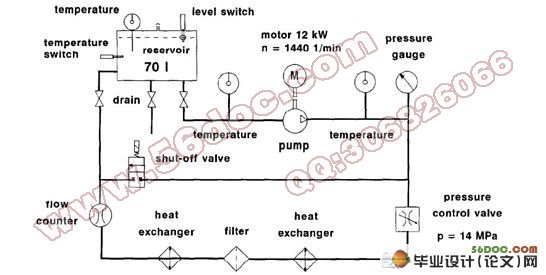

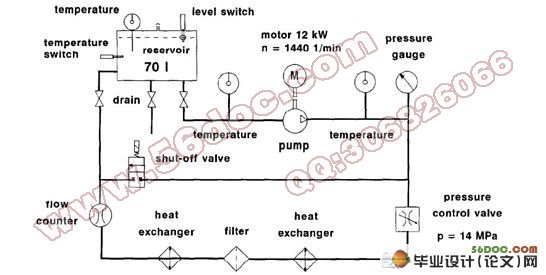

叶片泵的磨损状况标准方法是指示水力的失效流体(美国材料试验学会 D 2882/德国工业标准 51389)已经被通过用没有任何添加剂的润滑剂得到的失效计算和审查实验数据审查。除了依照德国工业标准得到的检验系列之外,泵的剖面温度已经用来自绝大部分联系原件和间缝润滑之间的温度作为失效计算的原始数据。根据德国标准检验的卷筒已经被前前后后严格的测试为了获得精确模型的原始数据和确定磨损位置。执行流体的性能分析和在液压环路中粒子磨损的调查。实验结果和预测的相比较,预测的是由协议核实负荷条件,时间磨损过程和当地的磨损证实的。已经得出关于合理的载荷消耗和失效校核的结论,就像这种方法在添加剂存在的适用性范围。

英文原文

wear 181-183 (1995) 868-875

Case Study

Theoretical and practical aspects of the wear of vane pumps

Part B. Analysis of wear behaviour in the Vickers vane pump

test

A. Kunz a, R. Gellrich b, G. Beckmann c, E. Broszeit a

a Institute of Material Science, Technical University Darmstadt, P.O. Box 11 1452, 64229 Darmstadt,Gcmb University for Technol08y, Economy and Social Science Zittau/Goditz, Facuky of Maihematics, P.O. Box 264, 02763 Zutau

cPetersiliensrr. 2d, 03044 Cottbus, Received 16 August 1994; accepted l November 1994

Abstract

The wear behaviour of the vane pump used in the standard method for indicating the wear characteristics of hydraulicfluids (ASTM D 2882/DIN 51 389) has been examined by comparison of the calculated wear and experimental data using alubricant without any additives. In addition to the test series according to DIN 51 389, temperature profiles from the pump have been analysed using the bulk temperatures of the contacting components and the temperature in the lubrication gap as input data for the wear calculation. Cartridges used in tests according to the Gennan standard have been examined extensively before and after each run to obtain input data for the mathematical model and to Jocate wear. An analysis of the :tluid properties and an investigation of the innuence of wear particles in the hydraulic circuit were performed. The experimental results were compared with the wear prediction, which was verified by the agreement in terms of load, temporal wear progress and local wear. Conclusions have been drawn with regard to the validity of the load assumptions and wear calculation, as well as to the limits of applicability of this method in the presence of additives.

Keywords: Vane pumps; Hydraulic fluids; Wear prediction; Vickers vane pump test

|