大米酸解酯化复合变性淀粉与大米淀粉膜的制备(11000字)

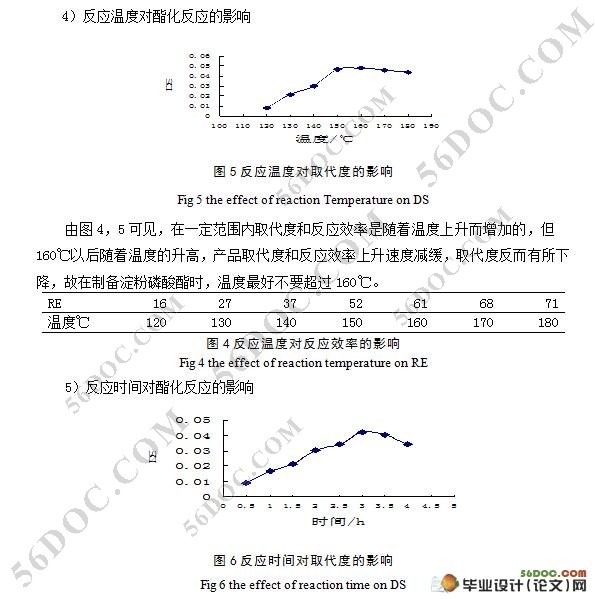

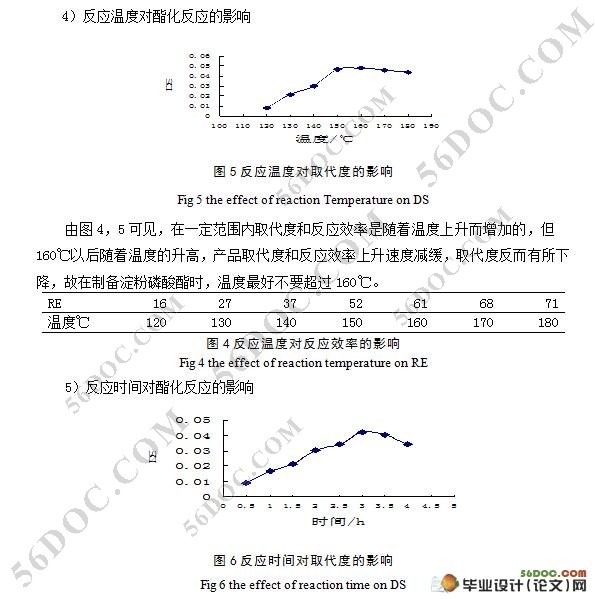

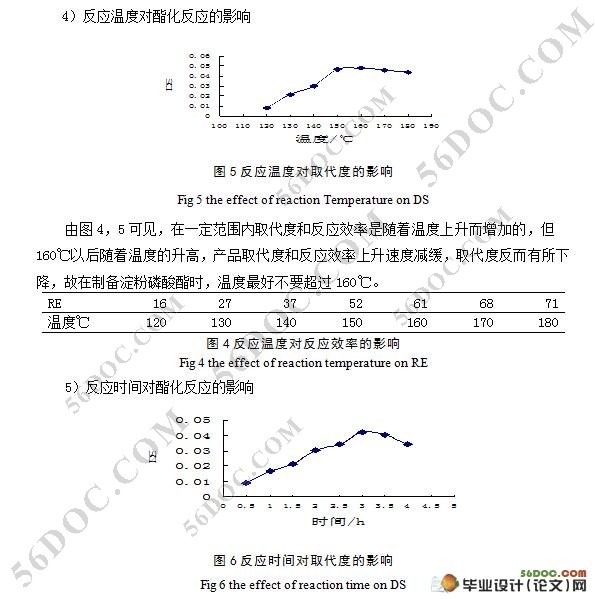

摘 要:本研究以大米淀粉为原料,先湿法酸解再进行酯化制备酸解酯化复合变性淀粉,将变性淀粉应用到制作淀粉膜的工艺中,由于淀粉膜易于降解,有利于环保。应用单因素试验确定了变性淀粉制备的条件,在固定酯化条件不变的情况下,根据之前单因素试验得到结果对酸解酯化条件进行试验确定,分析产品性质特点综合可得最佳酸解条件为2小时,0.5mol/L,35℃,最佳酯化条件为150℃,时间2h,磷酸盐10%,尿素6%。酸解酯化复合变性淀粉制膜的最佳条件为:甘油质量分数为1.0%,海藻酸钠质量分数0.5%,明胶质量分数0.7%,淀粉质量分数选择为10%,干燥温度为38℃。

关键词:可食用膜,变性淀粉,膜性能

Rice acid solution of composite modified starch esterification with rice starch membrane preparation

Abstract: This study rice starch as raw materials, first wet acid solution preparation acid solution then esterification of composite modified starch esterification, modified starch applied to production starch film process, because of starch membrane easily degraded, be helpful for environmental protection. Application determine the single factor experiment, the preparation of modified starch esterification conditions in fixed condition under the condition of invariable before a single factor experiment, according to get results reaction condition of acid solution tested, analysis to determine product characteristics can be best acid solution comprehensive conditions for 2 hours, 0.5 mol/L, 35 ℃, the best reaction condition for 150 ℃, time 2h, phosphates 10%, urea 6%. Acid solution denatured starch esterification composite membrane manufacture the best conditions for: glycerin quality score for 1.0%, sodium alginate quality score 0.5%, gelatin quality score 0.7%, starch quality score choice for 10% for 38 ℃, the drying temperature.

Key words:edible film, modifiled stracch ,membrane performance

|