即食泡椒鸭掌加工工艺研究

来源:wenku163.com 资料编号:WK1634631 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK1634631

资料介绍

摘 要:本试验以鸭掌为材料,参考传统泡椒凤爪制作工艺进行即食泡椒鸭掌的加工工艺进行研究。通过平行试验和正交试验,研究了预煮温度和时间、腌制配方和杀菌方式对产品的影响,结果表明:鸭掌经90~95℃预煮11min后,按泡椒与鸭掌的重量比例为2:5,鸭掌和腌制液的比例为1:6,腌制液的pH为4.0、白糖的浓度为2%、食盐的浓度为5%,腌制时间为3d,成品经过90~95℃杀菌20min,产品口感爽脆并且具有独特的泡椒风味。常温下保质期可达90d以上。

关键词:鸭掌;即食;加工;泡椒;

Study on Processing Technology of Duck's Palms

Abstract: In this experiment I choose duck's palms as the materials and make reference to the traditional production process of chicken's palms with picked peppers to study the processing . Through the parallel tests and orthogonal test, studies the pre-cooking temperature and time, salted formula and the effect of sterilization way for products.The result show that: First put the weighted duck feet cooked in the water with 90-95centi-degee for 11minuts. Then get the picked peppers as the two fifths of the weight of duck's palms. Second get the preserve salt liquid and make sure the water in it is five times more than water in duck's palms. And the PH of the preserve salt liquid is 4.0, the sugar concentration of it is 2% and the salt concentration is 5%. Third keep the duck's palms and picked peppers in the preserve salt liquid for three days. Last get the food sterilization at the centi-degree of 90-95 for 20 minutes. After all of these steps the duck's palms will taste wonderful with the smell of picked peppers. And the life for the duck's palms kept in room temperature is 90 days at least.

Key words: duck's palms; processing; picked pepper;

目 录 9400字

摘要………………………………………………………………………………1

关键词…………………………………………………………………………1

1前言……………………………………………………………………………2

2材料与方法……………………………………………………………………3

2.1原辅材料 …………………………………………………………………3

2.2 主要仪器 …………………………………………………………………3

2.3工艺流程…………………………………………………………………3

2.4 操作要点……………………………………………………………………3

2.4.1浸泡清洗…………………………………………………………………3

2.4.2 预煮………………………………………………………………………3

2.4.3 腌制液的制备以及腌制过程……………………………………………3

2.4.4 真空包装…………………………………………………………………3

2.5试验设计 ………………………………………………………………4

2.5.1预煮时间的确定………………………………………………………4

2.5.2 风味调配正交试验方案设计…………………………………………4

2.5.3 杀菌方式的确定……………………………………………………4

2.6 产品质量检测方法 ………………………………………………………4

2.6.1感官质量检测方法及标准……………………………………………4

2.6.2理化指标检测方法………………………………………………………5

2.6.3微生物指标检测方法……………………………………………………6

3试验结果与分析 ……………………………………………………………6

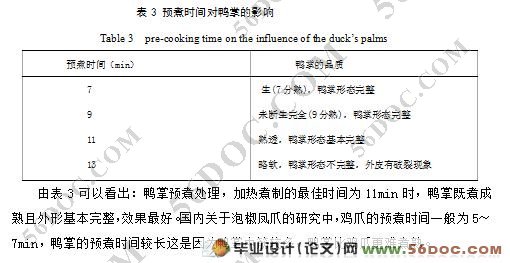

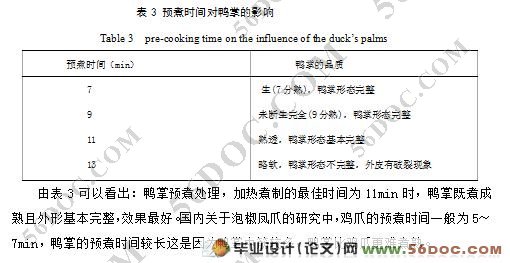

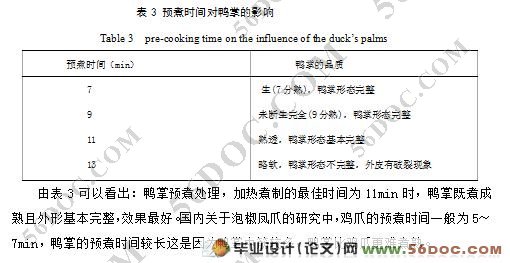

3.1预煮时间的确定……………………………………………………………6

3.2风味调配正交试验方案以及结果分析……………………………………6

3.3 验证试验确定最佳配方组合……………………………………………7

3.4杀菌方式的确定及结果分析………………………………………………8

3.5产品的检测结果…………………………………………………………9

3.5.1产品感官质量…………………………………………………………9

3.5.2理化、微生物检测结果…………………………………………………9

4 结论…………………………………………………………………………9

5讨论…………………………………………………………………………10

5.1去除腥味的探讨………………………………………………………10

5.2对产品风味的探讨………………………………………………………10

5.2杀菌方式的探讨…………………………………………………………10

参考文献 ………………………………………………………………………11

致谢……………………………………………………………………………12

|