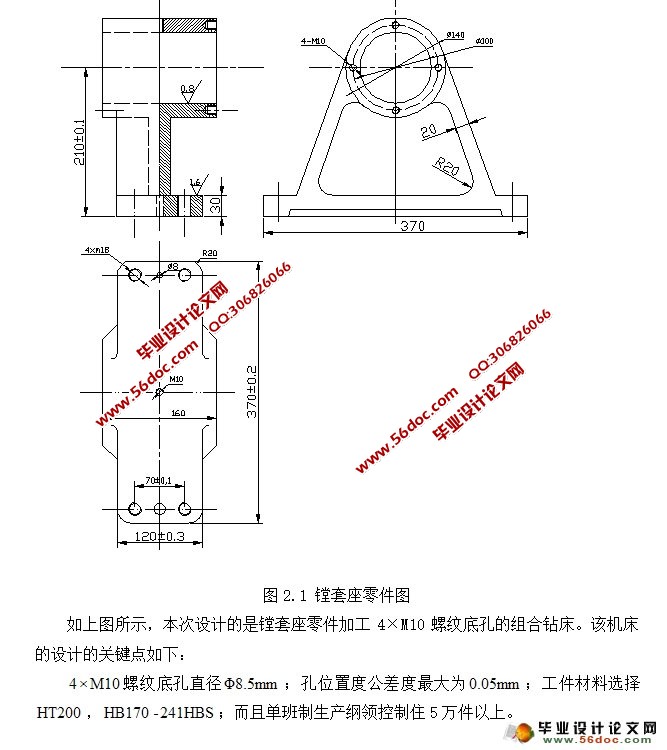

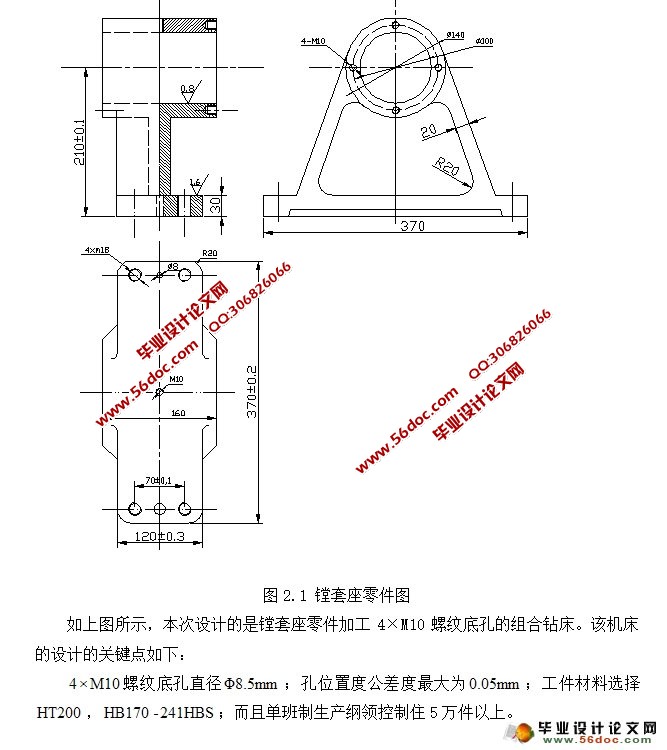

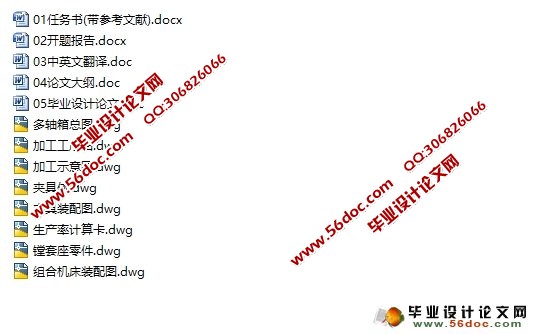

镗套座两侧面4×M10螺纹底孔组合钻床及夹具设计(含CAD图)(任务书,开题报告,外文翻译,论文说明书9200字,CAD图纸8张)

摘 要

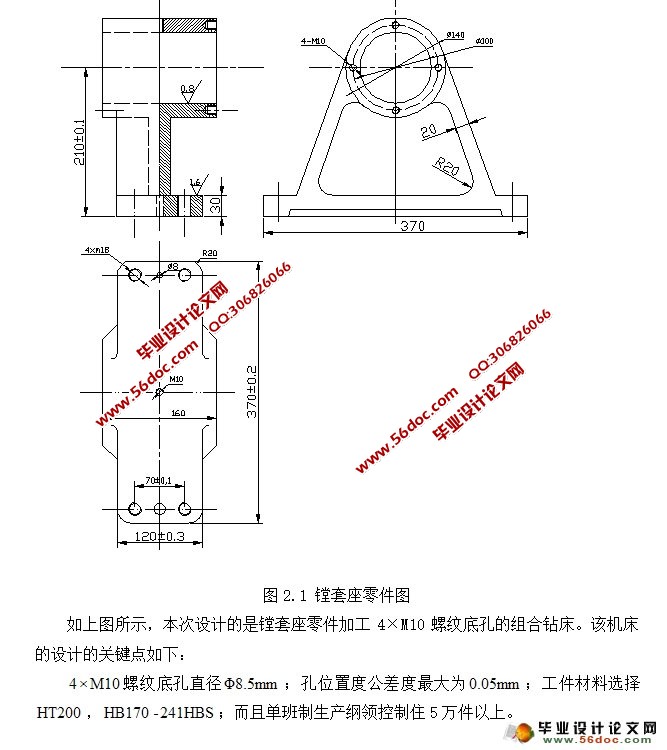

近年来,组合机床在机械制造业中的应用越来越多,对比传统机床,现在的组合机床最大的特点是根据高度集中的原则进行设计与制造,在工作中同时可以执行多道工序,组合机床具有效率高、加工精度高、成本低廉等特点。

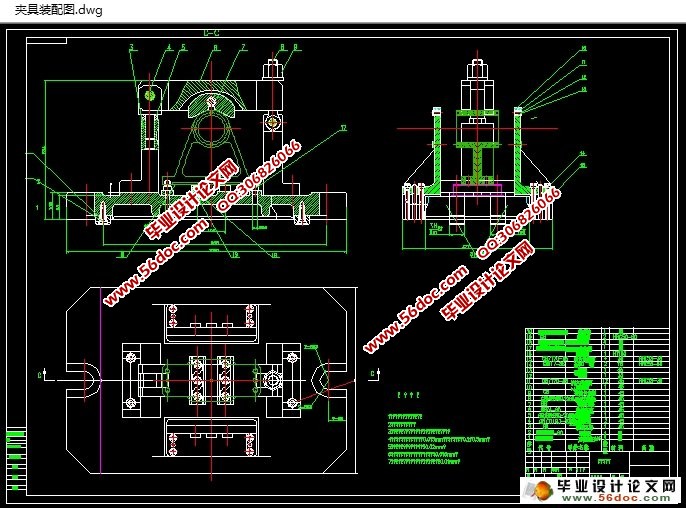

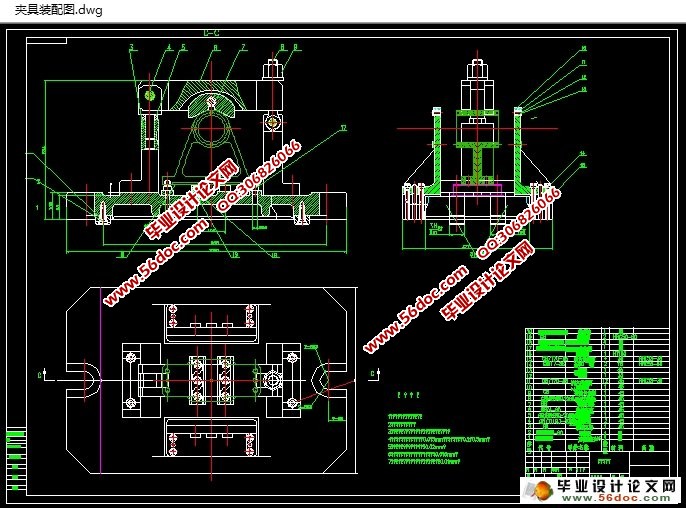

组合机床一般由床身、工作台和电源等基本部件组成,本设计根据镗座套加工工件尺寸和生产要求,合理的拟定设计方案,首先制定加工工序,其次合理地选择主轴、刀具、多轴箱和滑台等部件,然后设定主轴箱内传动系统,设计适合的夹具,最后完成组合机床系统的设计。

关键词:组合机床;设计;镗套座;夹具;

Development of modular machine tool

Abstact

In recent years, the combination of machine tool applications in machine manufacturing industry increasingly widespread, the machine is based on a combination of a high concentration of design principles, namely on one machine can process one step or more different processing steps. Compared with traditional machine tools, combined machine with high efficiency, high precision, low cost and so on.

Generally consists of a combination of machine bed, column, and supply some basic components , the design according to seat boring workpiece size and production requirements, the formulation of reasonable design, the first step of the development process, followed by a reasonable Select the spindle, tool, multi-axle and slide other components, then set the headstock transmission, designed for the fixture to finalize the design of modular machine tool systems.;

Keywords: combination machine; design; seat sets of boring; jig;

目录

摘 要 II

1 绪论 1

1.1 研究背景及意义 1

1.2钻孔组合机床概述 2

2 组合机床的总体设计 4

2.1 零件的分析 4

2.2 拟定组合机床的总体方案 5

2.3 确定切削用量及选择刀具 6

2.4 编制钻孔组合机床“三图一卡” 9

2.5 多轴箱的设计及校核 13

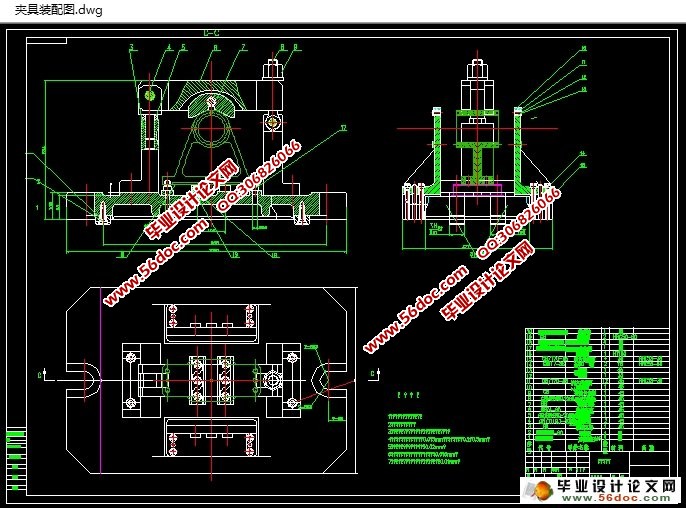

3 夹具设计 19

3.1 拟定夹具定位、夹紧方案 19

3.2 计算切削力及夹紧力 20

3.3 误差分析与计算 20

总结 22

参考文献 23

|