多孔涡轮的夹具设计(含CAD夹具图)(任务书,设计说明书11500字,CAD图纸1张)

摘要

机械制造技术不仅是衡量一个国家科技发展水平的重要标志,也是国际间科技竞争的重点。我国正处于经济发展的关键时期,制造技术是我们的薄弱环节。PC机进入数控领域,极大的促进了数控技术的发展,也为我国在数控生产领域赶超发达国家提供了机遇。跟上发展先进数控制造技术的世界潮流,将其放在战略优先地位,并以足够的力度予以实施,尽快缩小与发达国家的差距,在激烈的市场竞争中立于不败之地。同时,数控加工技术的发展孕育产生大量的数控专业技术人才,进而推动我国现代机械制造业进一步走向繁荣。

在机械制造各行业的工艺过程中广泛应用着各种不同的,用以固定加工对象,使之占有正确位置,以便接受施工的一种工艺装备,统称为夹具。因此,无论是在机械加工,装配,检验,还是在焊接,热处理等冷,热工艺中,以及运输工作中都大量采用夹具。但在机械加工中应用最为广泛的是金属切削机床上使用的夹具,我们称其为机床夹具。它在保证产品优质,高产,低成本,充分发挥现有设备的潜力,以便工人掌握复杂或精密零件加工技术,以减轻繁重的体力劳动等诸方面起着巨大的作用。因此,机床夹具的设计和使用是促进生产迅速发展的重要工艺措施之一。

本文主要围绕管接头及夹具设计为中心。,首先通过加工管接头让我们对夹具设计及机械加工有了初步的了解,特别是数控加工及零件夹具设计的了解更为深刻。然后,在导师的指导下,对零件加工设计及夹具设计方案进行分析和选择。选定方案后,。通过查阅相关零件加工及夹具设计书籍和相关图例在零件加工过程中,在查阅了相关文献后,参考相关资料完成零件的总体设计。

关键词:夹具;定位;夹紧力;箱体;

Abstract

Mechanical manufacturing technology is not only the important sign of weighing a national science and technology development level, is the focus of international technological competition. China is in a critical period of economic development, manufacturing technology is our weak link. PC access control field, has greatly promoted the development of NC technology, it provides the opportunity for China to overtake the developed countries in the field of CNC production. Keep up with the development of advanced NC manufacturing technology trends in the world, will be the priority strategy, and with enough strength to be implemented, narrow the gap with developed countries as soon as possible, remain invincible in the fierce competition in the market. At the same time, the development of NC machining technology has produced a lot of CNC professional and technical personnel, and promote China's modern machinery manufacturing industry further prosperity.

In the process of machinery manufacturing industries in a wide variety of applications, for processing a fixed object, so that possession of the correct position, to receive a construction techniques and equipment, collectively referred to as the fixture. Therefore, whether in the machinery processing, assembly, testing, or in welding, heat treatment and cold, heat process, and transport are a lot of work in a fixture. But in machining is the most widely used fixture using metal cutting machine tool, we called for the machine tool fixture. It guarantees product quality, high yield, low cost, and give full play to the potential of existing equipment, so that workers have complicated or precision parts processing technology, to reduce the heavy manual labor and other aspects play a huge role. Therefore, the design and use of machine tool fixture is one of the important measures to promote the rapid development of the technology of production.

This article focuses on the pipe joint and fixture design center. The first joint, let us have a basic understanding of the design and mechanical processing clamp through processing, especially the NC machining and parts of fixture design knowledge more profound. Then, under the guidance of tutor, to analyze and select parts processing design and fixture design. The selected scheme,. Through the relevant parts and fixture design books and related legend refer to in the process of machining parts, after having consulted the related literature, the overall design reference to relevant information to complete parts.

Key words:chucking;location;clamp force;box;

目 录

第一章 绪论 1

1.1 引言 1

1.2 课题研究现状及发展趋势 1

1.3 课题的理论依据及方案论证 2

1.4 课题研究的思路及步骤 3

第二章 机床夹具的作用 4

2.1 机床夹具的作用 4

2.2机床夹具的分类 4

2.2.1 按夹具的应用范围分类 4

2.2.2 按使用机床类型分类 5

2.2.3 按夹具动力源分类 5

2.3专用机床夹具的组成 6

第三章 转向箱箱体的零件实体及零件图的分析 7

3.1 转向箱箱体的三维实体模型 7

3.2 转向箱的零件图 8

3.3 对转向箱零件图的分析 8

第四章 夹具的设计 9

4.1 夹具设计说明 9

4.2 确定定位方案,设计定位装置 9

4.3 确定夹紧方案,设计夹紧装置 11

4.3.1 夹紧装置的种类和组成结构 11

4.3.2 对夹紧装置的基本要求 12

4.3.3 夹紧力的方向和作用点确定 13

4.3.4 夹紧力大小的估算 13

4.3.5 夹紧机构的选择 14

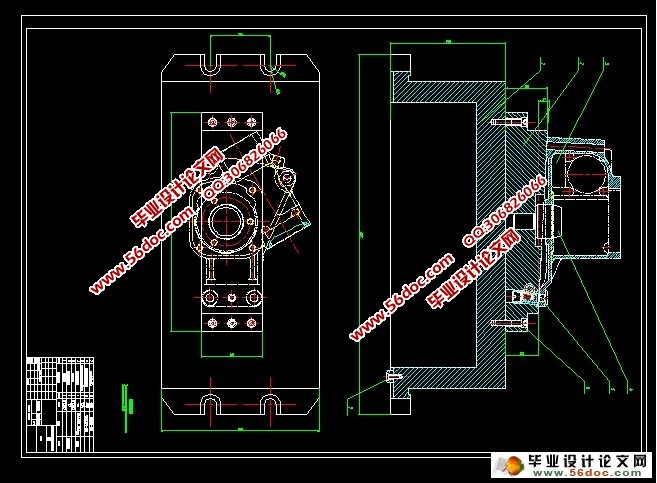

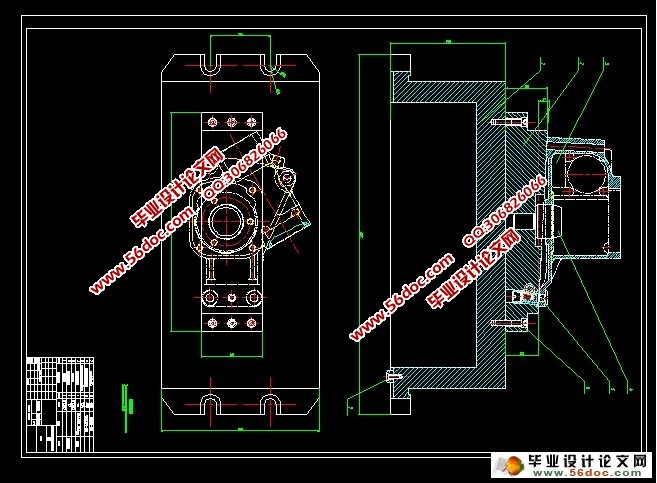

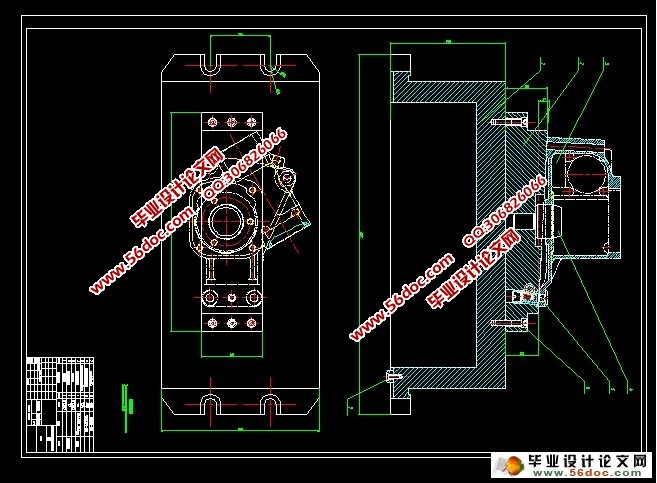

4.4 转向箱的夹具设计总图 16

第五章 夹具结构分析与设计 19

5.1 夹具的夹紧装置和定位装置 19

5.2 夹具的导向 21

5.3 钻孔与工件之间的切屑间隙 22

5.4 钻模板 23

第六章 总装配图的设计 25

6.1 总装配图的概述 25

6.2 总装配图的设计 25

结 论 27

参考文献 28

致 谢 29

|