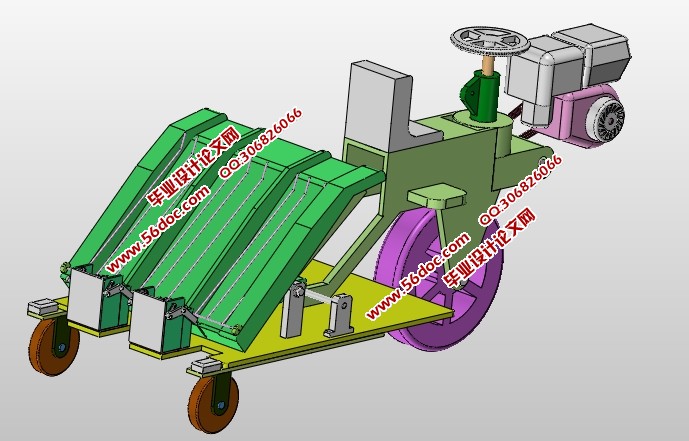

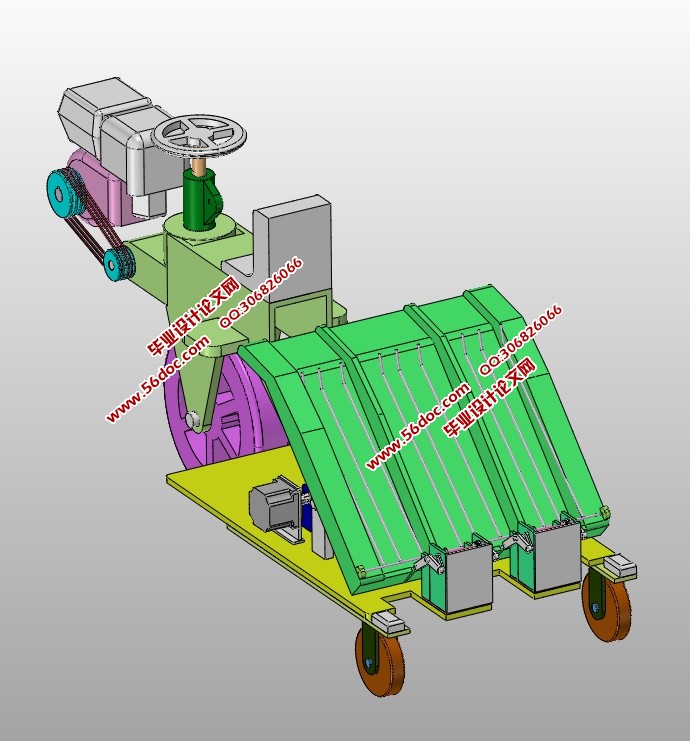

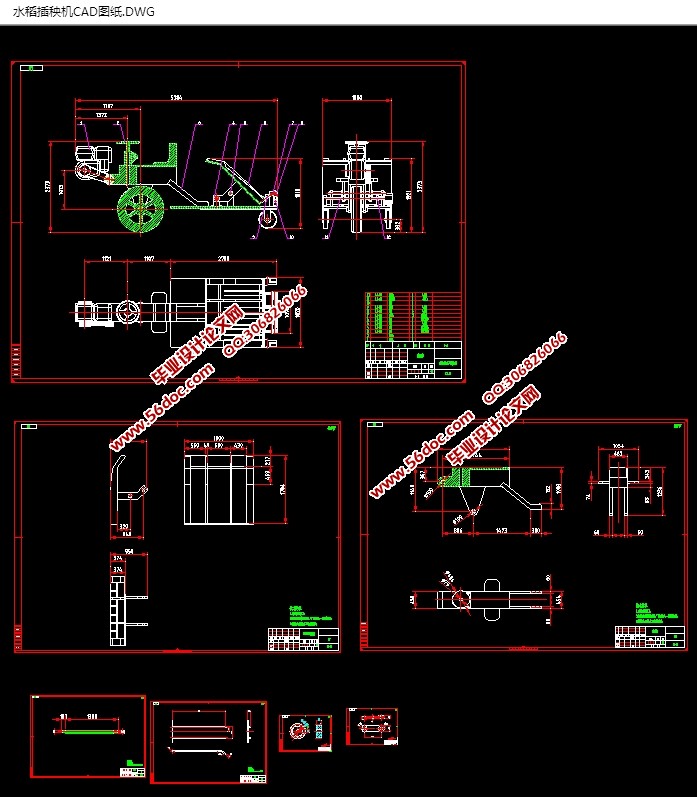

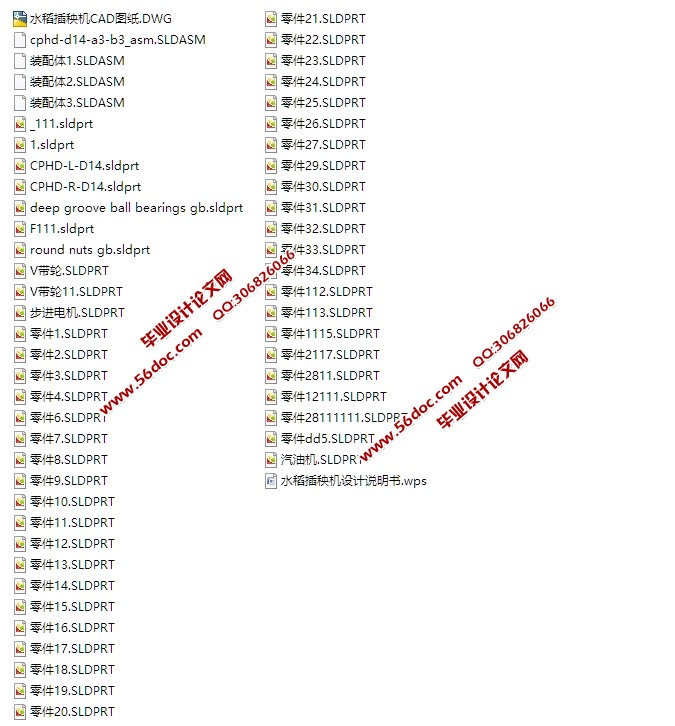

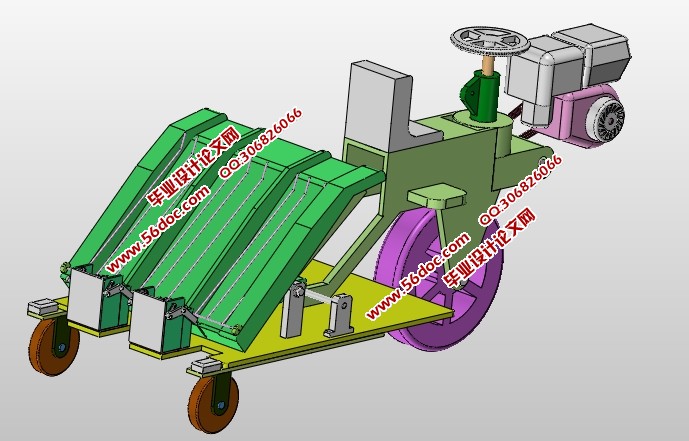

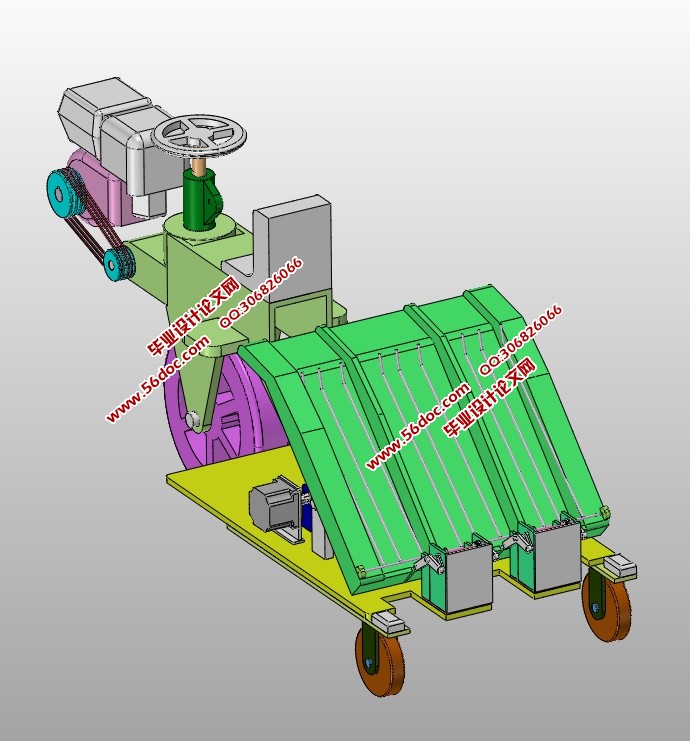

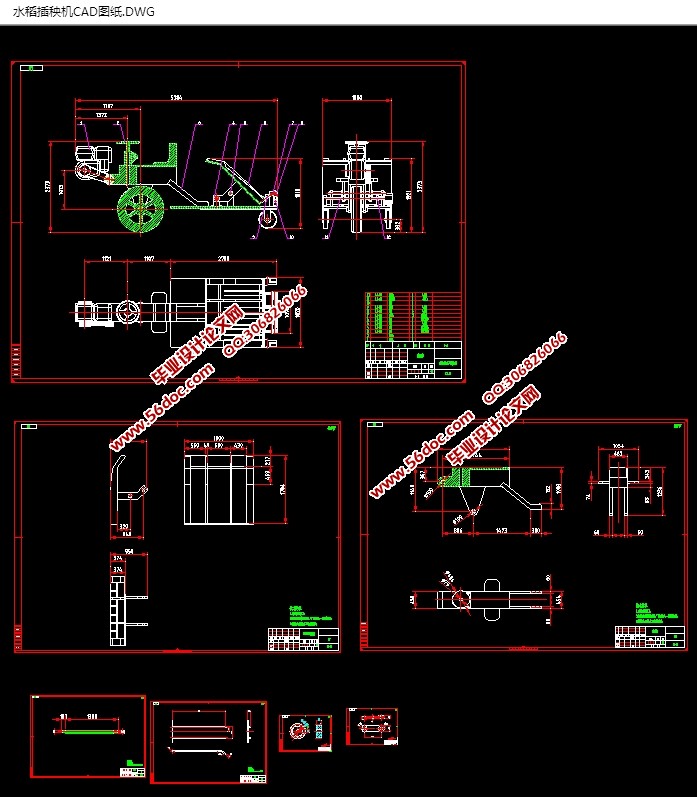

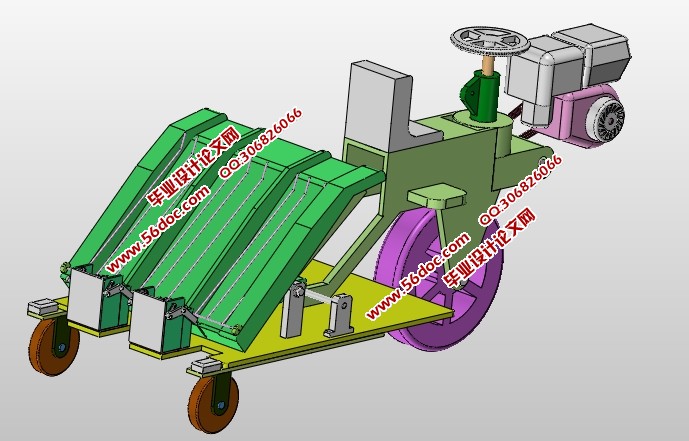

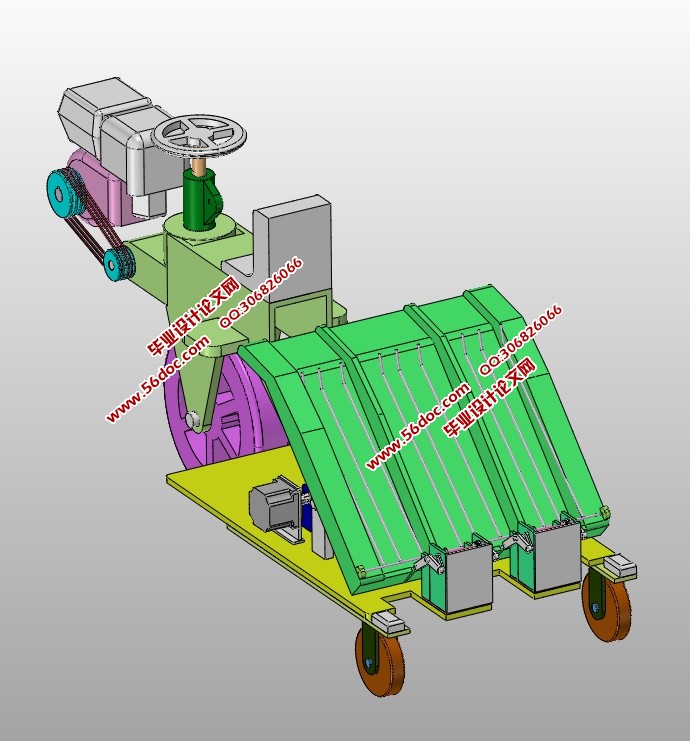

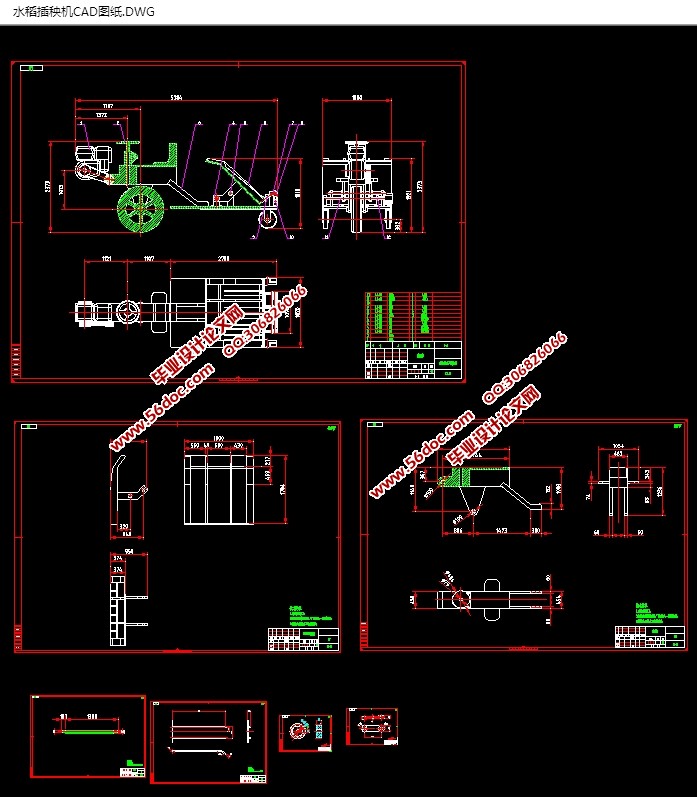

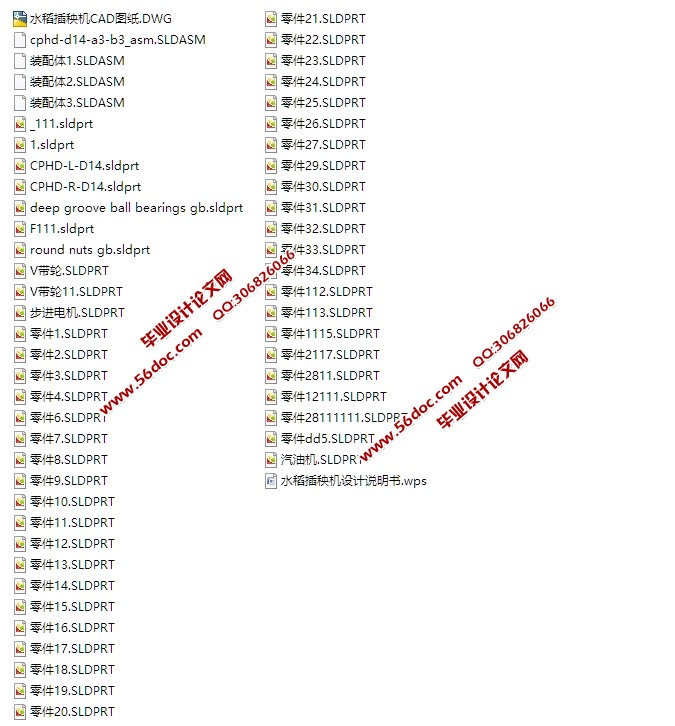

水稻插秧机的设计(含CAD图,SolidWorks三维图)(论文说明书13000字,CAD图纸7张,SolidWorks三维图)

摘要:当今社会,农业机械在机械工业中占据的比例越来越大,随着农耕的生产自动化,各种各样的农业机械将会出现并使用,本课题来源于当今社会机械工业水稻插秧设备的创新和更新换代基础之上,通过设计出水稻插秧机,从而来满足当今社会水稻插秧设备不足的缺陷。

国内水稻插秧机设备的研发及制造要与全球号召的高效经济、插秧质量好,效率高等主题保持一致。近期对机械行业中水稻插秧机的使用情况进行了调查,传统的水稻在没有水稻插秧机而需要人工插秧的情况下,效率低下,劳动强度大,所以设计一个专用的水稻插秧机势在必行。

文运用大学所学的知识,提出了水稻插秧机的结构组成、工作原理以及主要零部件的设计中所必须的理论计算和相关强度校验,构建了水稻插秧机总的指导思想,从而得出了该水稻插秧机的优点是高效,经济,并且插秧质量高,运行平稳的结论。

关键词: 水稻插秧机;质量;设计;经济;结论

The design of Ophiopogon japonicus seeder

Abstract:With the development of science and technology, interdisciplinary mutual infiltration, mutual exchanges between the various industry, extensive use of new structure, new materials, new technology, the sleeve pressing machine is large, efficient, reliable, energy saving,

Recently, the use of machinery industry, bearing and shaft sleeve shaft were investigated, found that the shaft, bearings and bushings in the machinery industry is one of the key parts.

Come very naturally in the assembly of the installation is also very simple. In the installation if the use of artificial pressure with not only the labor intensity is too large and the size of each other is not easy to ensure the shaft, bearing and shaft sleeve, so the design of a special press be imperative. Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve, pressing machine is efficient, economical, and high safety, stable operation. The overall plan .

the relative position of two axle sleeve on the plane, the motor reducer to provide power through belt drives the screw rod to rotate, and drives the head movement, a nut, a rotary motion of the linear motion of press. Block type safety clutch overload protection with teeth, pressure distribution in the corresponding position of the pipe after drilling through the drilling template.

Key words:Machine manufacture;Crankshaft;Processing craft;Fixture;

水稻插秧机的工作原理

本次设计的水稻插秧机的工作原理为:插秧机的设计是采用对秧块进行均匀切块的原理来实现分秧与插秧,达到定行、定深、定穴和定苗栽插的目的。只要盘苗上秧苗分布均匀,秧针切下的定量面积土块上的秧苗,即每穴秧苗的数量是较为均匀的,由于秧针主要是分离秧块,不是针对有生命的秧苗,伤苗的可能性大大降低。插秧机工作时,秧针插入带土秧块后抓取定量秧块,并下移,当移至设定的栽插深度时,插秧机构中的插植叉将秧苗从秧针上顶出,插入土中,完成一个栽插过程。同时,通过浮板和液压系统,控制浮板与秧针的相对位置,从而保持基本一致的插秧深度。

目 录

绪论 1

1. 课题的来源与研究的目的和意义 1

2. 水稻插秧机的发展现状 3

3. 水稻插秧机的类型 4

4. 水稻插秧机总体方案结构的设计 10

4.1 水稻插秧机的工作原理 12

5. 机械结构的设计 14

5.1 电机的选型计算 19

5.2 轴的设计计算 20

5.3 轴承的选型计算 20

6. 开沟器及其起落机构 21

6.1 开沟器的要求 22

6.2 开沟器的结构类型 22

6.2.1 芯铧式开沟器 23

6.3 水稻、秧箱 24

6.3.1 水稻、肥料箱容量计算 26

6.3.2 水稻、肥料箱结构特点 26

6.4 仿形机构 27

6.4.1 仿形机构类型 28

7. 三维软件设计总结 28

结论 29

参考文献 30

致谢 31

|