锤片式饲料粉碎机的设计(含cad零件图和装配图)(选题审批表,任务书,开题报告,中期检查表,毕业论文说明书17000字,CAD图纸7张)

摘 要:我国农村迫切需要一种高效、低耗、结构简单、一机多用、操作方便、使用安全小型饲料粉碎机。而国内现有小型饲料粉碎机普遍存在吨料电耗高的缺点,本设计以降低吨料电耗为主要目的,从增加粉碎能力和筛分效率入手,设计了一款锤片饲料粉碎机。

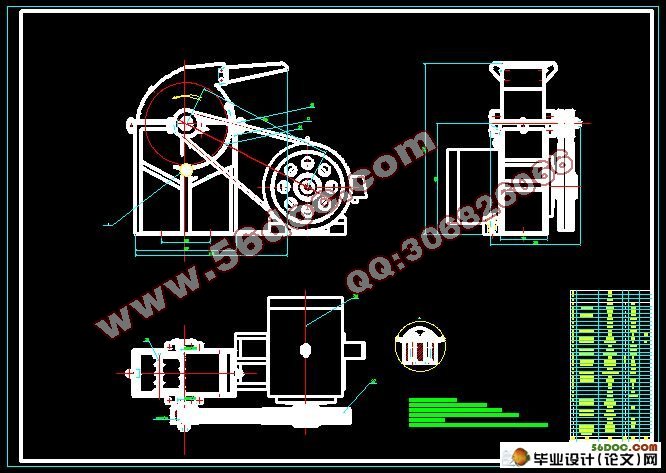

锤片式粉碎机是一种利用高速旋转的锤片来击碎饲料的机器,它具有通用性广、效率高、粉碎质量好、操作维修方便、动力消耗低等优点。本文对锤片式粉碎机进行了设计讨论。将重点对方案选择及总体设计、主轴的设计、箱体的结构设计进行深刻的研究和探讨。

关键词:饲料;锤片式粉碎机;设计

Design Of Hammer-shape Pulverizer Of Feed

Abstract:China rural urgently need a high efficiency, low consumption, simple structure, convenient operation, safe usage and small-sized pulverizer of feed.While domestic small-sized pulverizers generally exist such a disadvantage that high power consumption of each tons of material. This design aimed at low power consumption of each tons of material,started with the improvement of the ability of crushing and the efficiency of screening,so designed such a hammer-shape pulverizer of feed.

Hammer-shape pulverizer of feed was such a machine that made use of high-speed rotated hammer to shatter feed, which had many advantages,such as extensive usage,high efficiency, high quality of crushing, convenient operation and maintenance,low power consumption and so on.This paper designed hammer-shape pulverizer of feed and made discussion about it,especially its scheme selection,principal axis, tank body’structure and made profound research and exploration about them.

Key words: Feed;Hammer-shape pulverizer;Design;

目 录

摘要 1

关键词 1

1. 绪 论 2

1.1 国内外锤片式饲料粉碎机的技术现状 2

1.2 面前国内粉碎机的质量方面存在的主要问题 3

1.3 饲料粉碎机的种类和性能分析 3

1.4锤片式粉碎机技术发展研究的方向 5

2总体方案选择与设计 6

2.1总体方案 6

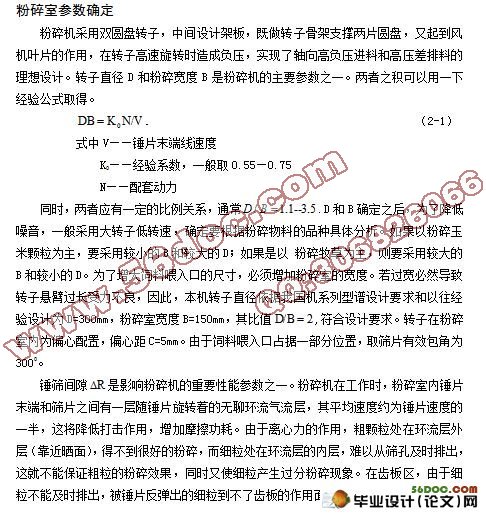

2.2粉碎室参数确定 7

2.3主要性能指标计算 8

2.4配套功率和电机的选择 9

3 带传动的设计 10

3.1 V带传动的特点 10

3.2 V带传动设计计算 10

4 轴和轴承的相关设计 14

4.1 轴的结构设计 14

4.2 主轴的校核 16

4.3滚动轴承寿命计算 20

4.4 滚动轴承润滑方式的选择 22

4.5连接键的选择和计算 22

5 转子的设计计算 23

5.1锤片的设计 23

5.2锤片架的设计 25

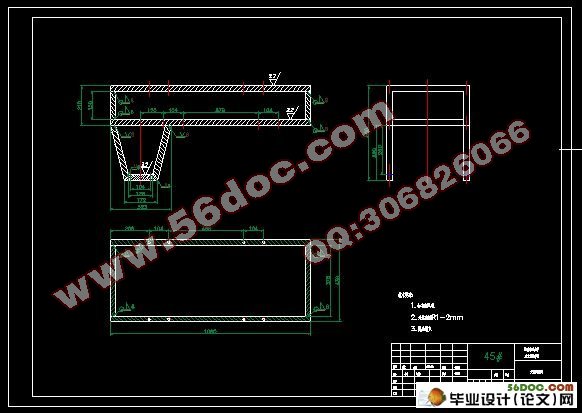

6筛片的设计 28

6.1粉碎机工作状态分析 28

6.2组合筛的结构和原理分析 29

6.3筛片的设计与选择 30

7.结论 32

参考文献 33

致谢 34

附录 34

|