采煤机摇臂设计(含CAD零件图装配图)(开题报告,中期检查表,外文翻译,论文说明书13000字,CAD图6张)

摘 要

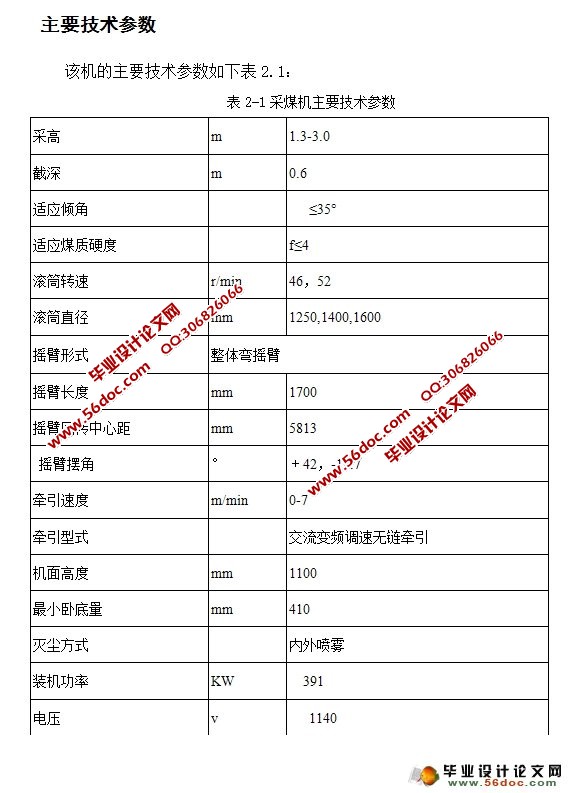

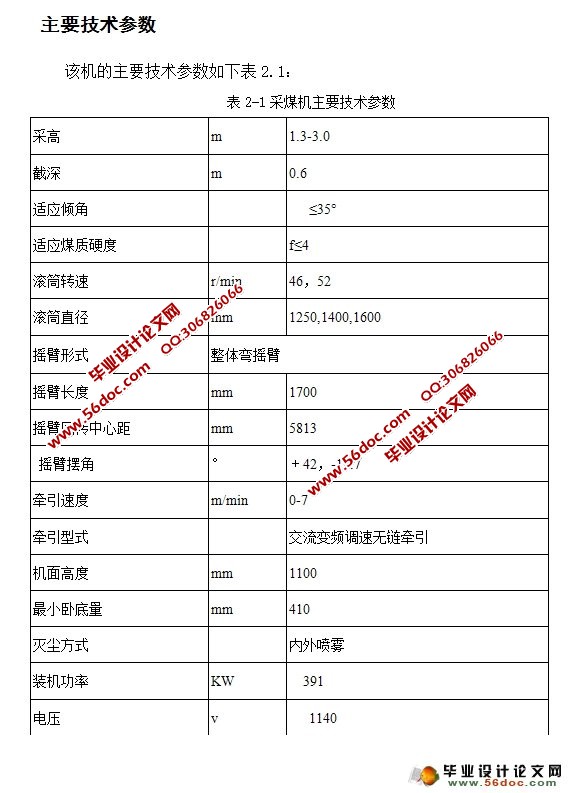

MG160/390-WD型采煤机是中等功率低采高的电牵引采煤机,用于煤层厚度1.5~2.92m的中厚煤层开采,采高1.3~3.0 m,煤层倾角小于35°,可采较硬煤质。

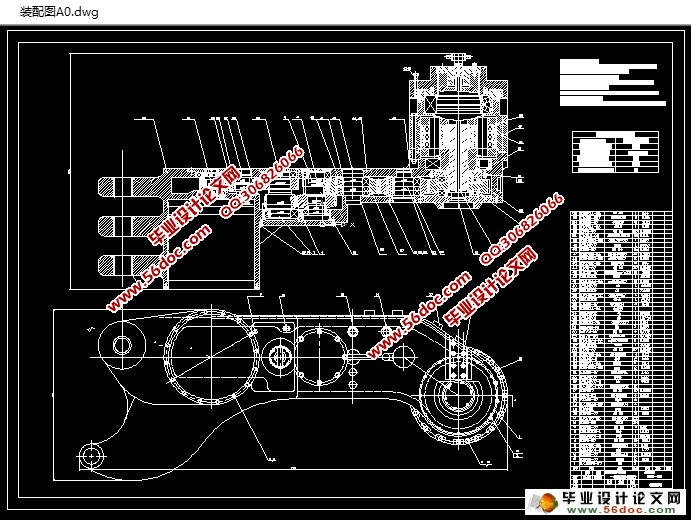

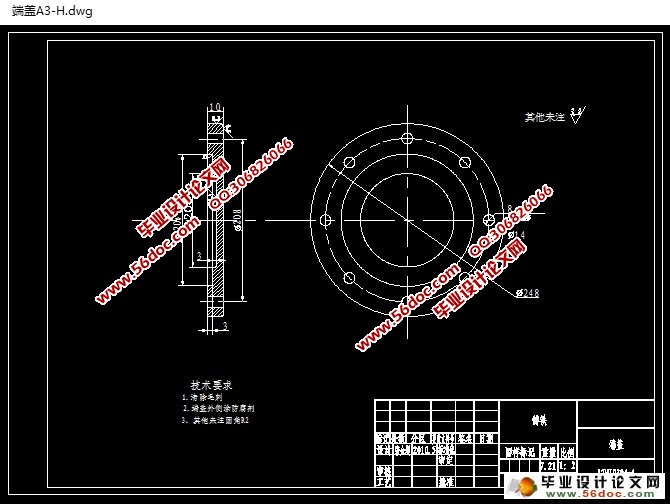

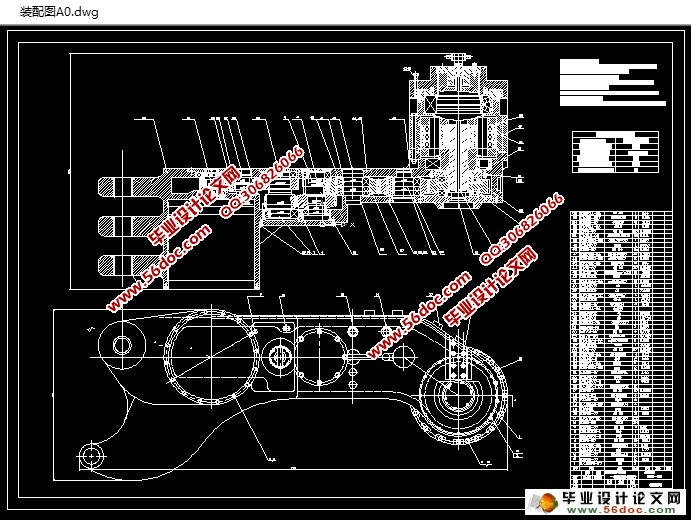

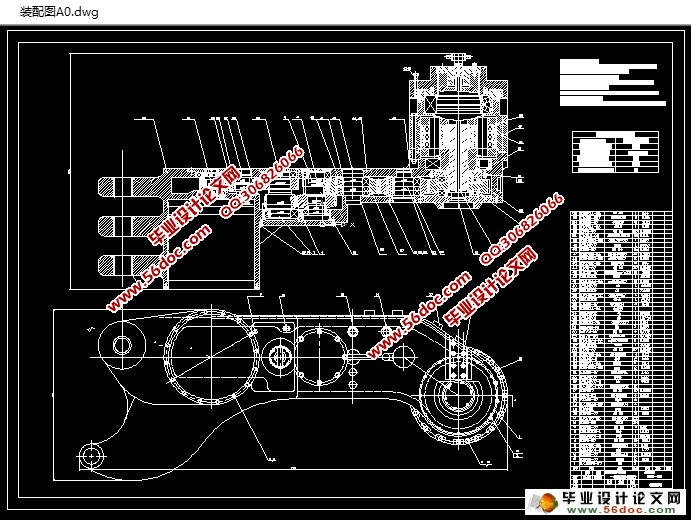

本论文完成了采煤机摇臂的设计,包括摇臂减速器的布局设计及三维建模。文中主要介绍了目前国内外采煤机的研究现状及未来发展趋势,同时介绍了采煤机的类型、工作原理和主要组成,还介绍了采煤机摇臂的具体结构。

在设计过程中,重点完成了对减速器传动方案的确定和相关组件的计算和设计。首先,完成了对摇臂减速器的传动比分配,转速及传递功率的计算,其次,完成了采煤机摇臂壳体内一轴、二轴、三轴、四轴、五轴和各轴传动齿轮的设计及校核,简单介绍了行星轮系的装配关系确定和强度校核。再次,完成了轴承和联接花键的选择及校核。最后,对采煤机摇臂进行了三维建模。

关键词:采煤机;摇臂;齿轮

ABSTRACT

The MG160/390-WD shearer is a medium-low power electric haulage shearers mining medium-thick seam, for coal seam thickness of 1.5~2.92m, mining height 1.3~3.0m,coal bed pitch less than 35°, it can be used for hard coal mining.

Double drum coal shearer。A mining full-seam mining machine, one at each end of the drum. Front roller in cutting top coal, after cutting drum in under ground coal. Two roller are generally dorsal rotation, the driver left drum left spiral, the driver right right helical drum. Can also rotate in the opposite direction, the driver on the left with the right spiral drum, the drum with a left screw driver. Generally use the two-way mining, advanced shift after the head of the oblique cutting knife; also can be used to feed at the same time shift head tangent feeding mode.

This paper completed the design of shearer rocker arm, including the layout and three-dimensional modeling of speed reducer, it described the current status of domestic and international coal mining research and future development trends, the type of shearer, working principles and main components,it also introduced the specific structure of shearer rocker.

In the design process, completed the calculation and design of the reducer drive scheme and related components. First, completed the rocker reducer transmission ratio , speed and transfer power distribution calculation. Secondly, the completion of the design and check of five shafts and the shaft driving gears inside the rocker arm shell,simply introduced the assembly relationships and intensity checking of the planetary gear train. Thirdly, the completion of the selection and check the spline for connection. Finally, the three-dimensional modeling.

Keyword: shearer; rocker arm; gear

目录

1 绪论 1

1.1 设计思路的提出 1

1.2 采煤机概述 2

1.2.1 采煤机分类及组成 2

1.2.2 滚筒采煤机工作原理 3

1.3 采煤机械化的发展与趋势 4

2 摇臂整体方案确定 5

1.4 本章小结 5

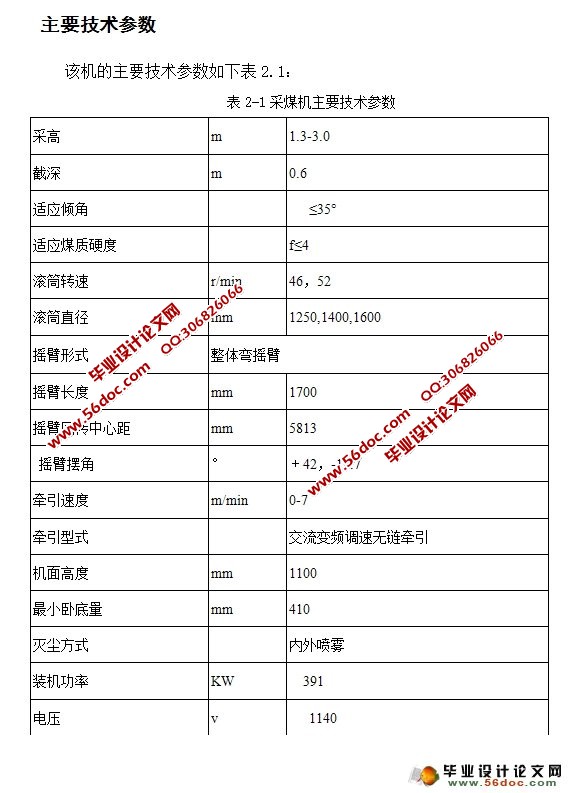

2.1 MG160/390-WD型采煤机简介 5

2.1.1主要技术参数 6

2.1.2 MG160/390-WD 型电牵引采煤机截割部组成 7

2.1.3 截割部电动机的选择 7

2.2 摇臂具体结构设计方案的确定 8

2.3 传动方案的确定 9

2.3.1 传动方式确定 9

2.3.2 传动比的确定 10

2.4 传动比的分配 11

2.5 传动效率选择 12

2.6 本章小结 13

3 传动系统设计 14

3.1 各级传动转速、功率、转矩的确定 14

3.2 齿轮设计及强度效核 15

3.2.1 齿轮2(惰轮)和齿轮3的设计及强度效核 16

3.2.1 齿轮4和齿轮5的设计及强度效核 16

3.2.3 齿轮6和齿轮7(惰轮)设计及强度校核 20

3.2.4 验算齿轮3和齿轮6是否干涉 22

3.2.5 行星齿轮设计及强度校核 22

3.3 轴的设计及强度效核 33

3.3.1 Ⅳ轴的设计及强度效核 33

3.3.2 Ⅲ轴的设计及强度效核 38

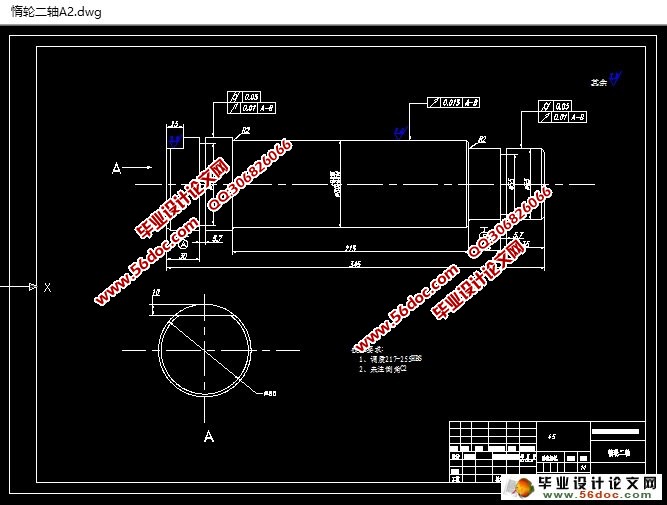

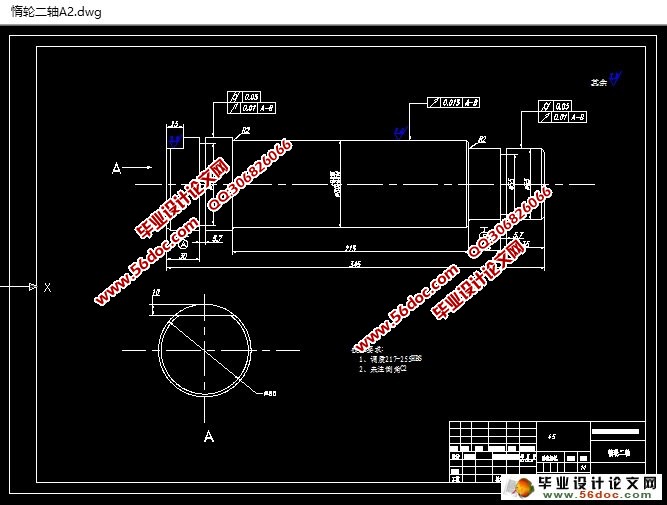

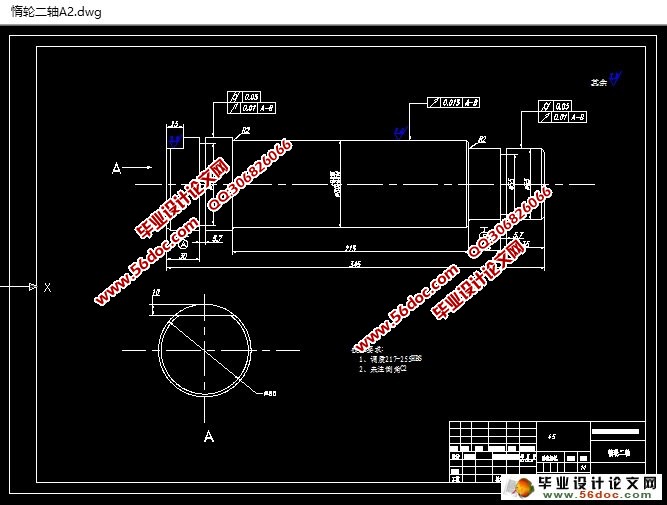

3.3.3 惰轮Ⅰ轴的设计及强度效核 43

3.3.4 惰轮Ⅱ轴的设计及强度效核 47

3.4 轴承的寿命校核 53

3.4.1 Ⅲ轴轴承的寿命校 53

3.4.2 Ⅱ轴轴承的寿命校核 54

3.4.3 Ⅰ轴轴承的寿命校核 55

3.4.4 Ⅱ轴轴承的寿命校核 56

3.5 花键的选择与强度校核 57

3.5.1 Ⅲ轴花键的强度校核 57

3.5.2 Ⅱ轴花键的强度校核 58

3.6 摇臂的润滑与维护 12

3.7 本章小结 59

4 摇臂的三维建模 60

4.1 基于PRO/E的参数原理 60

4.2 基于PRO/E的模拟仿真 60

4.3 减速器参数化设计及仿真的总体方案及技术路线 60

4.4 摇臂三维实体建模 62

4.5 本章小结 64

5 致 谢 60

6 外文翻译 66

|