前言

毕业设计是学生在学完教学计划所规定的全部课程后,总结在校学习成果,应用自己所学知识和能力进行的一次综合性的大实践,在校学习的最后一环,必将对毕业后的工作产生深远的影响。毕业设计培养和锻炼自己对所学知识的灵活应用,通过毕业设计,可以掌握正确的设计方法和设计思维方法,进一步提高自己有关机械制造工艺及设备方面的设计能力,提高制图、计算、文字叙述、运用各种标准、规范、手册的能力,学会调查研究、理论联系实际、锻炼查阅、分析研究国内外有关资料的能力,巩固并扩大知识领域和视野,学习本专业范围内与设计题目有关的专业知识,使自己得到更好的锻炼,以能够胜任将来的工作的需要。

随着现代机械工业的发展,机床的种类越来越繁多,机床的功能越来越多,为了适应当今机械生产中的特殊要求,专用机床的应用越来越广泛。之所以选择套筒十字槽铣削专机设计作为我的设计题目,是因为我发现以前的铣床虽然功能不少,但是有很多不足之处,比如对工件大批量生产不能满足,而且生产效率不高,对一些有特殊要求的工件也不能进行批量生产。基于这个前提,我选择了铣削类的专机设计,主要是针对套筒十字槽的铣削进行加工。通过本次设计,可以生产出一种铣床满足套筒十字槽的铣削标准化批量生产,这种铣床既可以满足特殊的加工要求又节省了时间、减少了劳动力。本毕业设计的目的是设计出一种铣削类的专用机床,让它只对套筒十字槽这一类材料进行铣削加工。本机床结构简单、集中化程度高、针对性强、工作效率高、能够适应在生产批量大的生产中的要求。它既提高了生产效率,又简化了操作程序,而且减轻了工人的劳动强度。

由于较早以前的铣床应用领域比较狭窄,并且对加工特殊要求的工件还不能满足,这样就引起了一场技术革命,铣床得到了广泛改进,它的应用范围也大幅度扩大,对铣床新的技术研究从未停止过。铣床是用多刃铣刀进行铣削加工的机床,铣刀的旋转为主运动。由于平面的铣削比刨削生产效率高,因此,早先的铣床是取代刨床而出现的。后来刀具技术提高了,能够制造各种复杂形状的铣刀,因而铣床从铣削平面扩大到能加工各种沟槽、螺旋面、回转面、齿形面以及复杂的空间曲面。铣床的类型较多,为适应加工工件的尺寸和重量,铣床的类型有:升降台铣床、无升降台铣床和龙门铣床;为适应批量生产的有:圆工作台铣床、双端面铣床和鼓轮铣床;为适应某些特殊工件加工而发展的有:工具铣床、键槽铣床、曲轴铣床;为适应加工复杂曲面的有:液压仿形铣床、电气仿形铣床、数字程序控制铣床等。此外,还有与镗削加工相结合的铣镗床以及与磨削加工相结合的铣磨床。

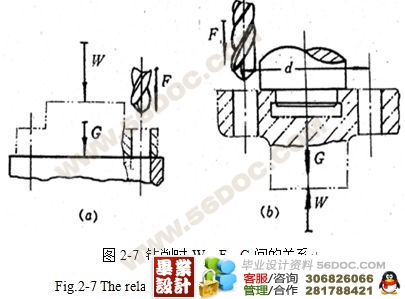

当然在铣床中夹具的设计也是至关重要的,由于夹具设计过程的随机因素较多,目前仍有许多企业沿用传统的设计方法来完成,即由经验丰富的工艺人员人工设计(或借助二维CAD设计)。很显然,这种设计方法在很大程度土受夹具设计者的经验和知识水平的限制,且设计周期长,设计效率低,劳动强度大,已不适应现代制造技术。因此,开发出实用的计算机辅助夹具设计系统是解决这一间题的重要方法和手段。计算机辅助设计可以分为概念设计、技术设计和详细设计三个阶段。概念设计是计算机辅助夹具设计中最关键的一个环节,它影响着后续的技术设计和详细设计,是决定夹具方案优劣的重要阶段。由于铣削加工切削用量及切削力较大,又是多刃断续切削,加工时易产生振动,因此设计铣床夹具时应注意:夹紧力要足够且反行程自锁;夹具的安装要准确可靠,即安装及加工时要正确使用定向键、对刀装置;夹具体要有足够的刚度和稳定性,结构要合理。

铣床是用铣刀对工件进行铣削加工的机床。铣床除能铣削平面、沟槽、轮齿、螺纹和花键轴外,还能加工比较复杂的型面,效率较刨床高,在机械制造和修理部门得到广泛应用。

本次设计主要包括两大部分。

第一部分为套筒十字槽铣削专机的设计,其中包括铣床的基本尺寸的选择、电机的选择、传动系统的设计和铣刀的选择。

首先,铣床的基本尺寸主要参考常用铣床的外形尺寸,并根据它的需要来确定。可根据45钢的切削性能及铣削时的铣削用量和铣削速度来估算出铣削力和铣削功率来,并根据铣削功率选择电动机。然后,根据所选电机的同步转速和铣削速度来确定传动比,并用齿轮传动系统来实现。由于是加工套筒十字槽的铣床,所以根据工件的需要,选择最有利的铣削速度,不需要变速,采用单级传动即可。

第二部分为专用夹具的设计,其中包括定位方式的选择、定位误差的计算、夹紧方式的确定、夹紧力的确定及夹紧机构的的选择、导引装置的确定、夹具体的设计和夹具体在机床上的定位方式。

根据六点定位原理、套筒十字槽的特点及常用定位元件的种类,来确定夹具体的定位方式。由于零件在加工时,总会产生误差,因此应考虑工件的定位误差。进行定位误差的计算,以保证定位误差在零件加工误差允许的范围之内。若不合适,则应选择更合适的定位方式,以确保零件的加工精度。为了使零件在被加工时保持位置不变,应对零件在被加工时所需的夹紧力进行估算。在此基础上,综合考虑零件的定位方式和加工方式,来设计适合的夹紧机构。为保证加工精度,选择合适的对刀导引装置,保证工件相对于刀具处于正确的位置。综合以上各方面的设计和各个装置的相对位置关系,可以设计出夹具体的结构。并且还要确定夹具体在机床上的定位方法和定位精度。这样就完成了夹具的设计。

由于此次设计是根据实际生产加工中的需要来进行设计的,因此还从经济性方面分析了此次设计的可行性。另外,分析了此次设计相对于一般生产加工情况的优点、此次设计的不足,和可能改进的方法。

关键词:铣削加工 复杂

The graduation project is a student after study the plan of instruction stipulated complete curriculum, summarizes in the school study achievement, applies itself to study a comprehensive big practice which the knowledge and ability carry on, in the school study the link, will certainly to have the profound influence last after the graduation work. The graduation project raises and exercises itself to study the knowledge the nimble application, through the graduation project, may master the correct design method and the design thought method, further enhances oneself related machine manufacture craft and equipment aspect designed capacity, enhances the charting, the computation, the writing narration, to utilize each kind of standard, the standard, handbook ability, the academic society investigation and study, the apply theory to reality, the exercise consult, analytical study domestic and foreign pertinent data ability, consolidates and expands the area of knowledge and the field of vision, studies in this specialized scope with the design topic related specialized knowledge, enables itself to obtain a better exercise, by can be competent future work need.

Along with the modern mechanical industry's development, engine bed's type is getting more and more, engine bed's function are getting more and more, to adapt now in the machinery production special request, special purpose machine's application is getting more and more widespread. The reason that the choice sleeve cross trough milling special plane design takes my design topic, is because I discover the beforehand milling machine, although the function many, but has many deficiencies, for instance cannot satisfy to the work piece production in enormous quantities, moreover the production efficiency is not high, has the special request work piece to some not to be able to carry on the volume production. Based on this premise, I have chosen the milling class special plane design, is mainly aims at the sleeve cross trough's milling to carry on the processing. Through this design, may produce one kind of milling machine to satisfy the sleeve cross trough's milling standardization volume production, this kind of milling machine both might satisfy the special processing request and to save the time, to reduce the labor force. This graduation project's goal is designs one kind of milling class the special purpose machine, lets it only carry on the milling processing to sleeve cross trough this kind of material. This engine bed structure is simple, the centralized degree high, pointed strong, the working efficiency high, can adapt in the production lot big production request. It both raised the production efficiency, and simplified the operation sequence, moreover reduced worker's labor intensity.

Because the beforehand milling machine application domain is quite early narrow, and to processes the special request the work piece not to be able to satisfy, like this caused a technological revolution, the milling machine obtained the widespread improvement, its application scope also large scale expanded, has never stopped to the milling machine new engineering research. The milling machine is carries on the milling processing with the multi-edge milling cutter the engine bed, milling cutter's revolving primarily movement. Because the plane milling is higher than the shaping production efficiency, therefore, the previous milling machine substitutes for the mechanical slicer to appear. Afterward the cutting tool technology enhanced, can make each kind of complex shape the milling cutter, thus the milling machine expands from the milling plane to can process each kind of trench, the helicoid, the plane of rotation, the tooth profile surface as well as the complex space-like surface. Milling machine's type are many, for the adaptation processing work piece's size and the weight, milling machine's type includes: Fluctuation bench miller, non-fluctuation bench miller and planer-type milling machine; Includes for the adaptation volume production: Circle work bench miller, double-end surface milling machine and drum wheel milling machine; In order to adapt certain special work piece processing to develop includes: Tool milling machine, slot-milling machine, crank milling machine; Includes for the adaptation processing complex surface: Hydraulic pressure profiling machine, electricity profiling machine, digital process control milling machine and so on. In addition, but also has the mill boring lathe which as well as the mill grinder which unifies with the boring processing unifies with the abrasive machining.

Certainly in the milling machine jig's design is also very important, are many as a result of the jig design process's random factors, at present still had many enterprises to continue to use traditional the design method to complete, namely designs artificially by the experienced craft personnel (or draws support from the two-dimensional CAD design). Very obviously, this design method in very great degree earth jig designer's experience and state-of-art limit, and the design cycle is long, the rated capacity is low, the labor intensity is big, did not adapt the modern technique of manufacture. Therefore, develops the practical computer auxiliary jig design system is solves this topic important method and the method. The computer-aided design may divide into the conceptual design, the technical design and the detailed design three stages. The conceptual design is in the computer auxiliary jig design a most essential link, it is affecting the following technical design and the detailed design, is decides the jig plan fit and unfit quality the crucial stage. Because the milling processing cutting specifications and the cutting force are big, when is the multi-edge interrupted cutting, the processing easy to have the vibration, therefore time design milling jig should pay attention: The clamping force must and enough counter-traveling schedule self-locking; Jig's installment wants accurately reliable, namely when installment and processing must use the directional key, install correctly to the knife; The jig body must have the enough rigidity and the stability, the structure must be reasonable.

The milling machine is carries on the milling processing with the milling cutter to the work piece the engine bed. The milling machine besides can the milling plane, the trench, the gear teeth, the thread and the spline shaft, but can also process the quite complex profile, the efficiency compares the mechanical slicer to be high, obtains the widespread application at the machine manufacture and the repair department.

This design mainly includes two major parts.

The first part for sleeve cross trough milling special plane's design, including milling machine's basic size choice, electrical machinery's choice, transmission system's design and milling cutter's choice.

First, milling machine's basic size main reference commonly used milling machine's external dimensions, and need to determine according to it. May act according to 45 steel time the cutting values and the milling milling amount used and the milling speed estimates the milling strength and the milling power comes, and according to milling power choice electric motor. Then, according to chooses electrical machinery's synchronous speed and the milling speed determines the velocity ratio, and realizes with the gear drive system. Because processes the sleeve cross trough's milling machine, therefore according to the work piece need, chooses the most advantageous milling speed, does not need to change speed, uses the single stage transmission then.

The second part for unit clamp's design, including the locate mode the choice, position error's computation, the clamp way determination, the clamping force determination and the clamp organization choice, guidance device determination, jig body's design and jig body's on engine bed locate mode.

According to six localization principles, sleeve cross trough's characteristic and the commonly used setting element's type, determines the jig body's locate mode. Because components in processing time, the general meeting has the error, therefore should consider the work piece the position error. Carries on position error's computation, guarantees the position error, in the components processing error permits in scope. If is inappropriate, should choose the more appropriate locate mode, guarantees the components the working accuracy. In order to cause the components when is processed the hold position is invariable, deals with the components when is processed needs the clamping force carries on the estimate. Based on this, the overall evaluation components' locate mode and the processing way, design the suitable clamp organization. For the guarantee working accuracy, chooses appropriately to the knife guidance device, guaranteed that the work piece is opposite in the cutting tool is in the correct position. Above the synthesis various aspects' design and each installment's relative position relations, may design the jig body's structure. And must determine the jig body's on engine bed localization method and the pointing accuracy. This has completed jig's design.

Because this design is needs to come according to the actual production processing to carry on the design, therefore has also analyzed this design feasibility from the efficient aspect. Moreover, analyzed this design to be opposite in the general production processing situation merit, this design insufficiency, with method which possibly improved.

铣床的简介

最早的铣床是美国人惠特尼于1818年创制的卧式铣床;为了铣削麻花钻头的螺旋槽,美国人布朗于1862年创制了第一台万能铣床,这是升降台铣床的雏形;1884年前后又出现了龙门铣床;二十世纪20年代出现了半自动铣床,工作台利用挡块可完成“进给-决速”或“决速-进给”的自动转换。

由于较早以前的铣床应用领域比较狭窄,并且对加工特殊要求的工件还不能满足,这样就引起了一场技术革命,铣床得到了广泛改进,它的应用范围也大幅度扩大,对铣床新的技术研究从未停止过。铣床是用多刃铣刀进行铣削加工的机床,铣刀的旋转为主运动。由于平面的铣削比刨削生产效率高,因此,早先的铣床是取代刨床而出现的。后来刀具技术提高了,能够制造各种复杂形状的铣刀,因而铣床从铣削平面扩大到能加工各种沟槽、螺旋面、回转面、齿形面以及复杂的空间曲面。铣床的类型较多,为适应加工工件的尺寸和重量,铣床的类型有:升降台铣床、无升降台铣床和龙门铣床;为适应批量生产的有:圆工作台铣床、双端面铣床和鼓轮铣床;为适应某些特殊工件加工而发展的有:工具铣床、键槽铣床、曲轴铣床;为适应加工复杂曲面的有:液压仿形铣床、电气仿形铣床。

工件的加工工艺性分析

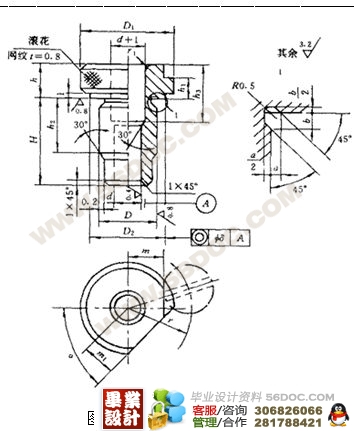

因采用立式钻床,待加工孔处于垂直位置。若设平行于待加工孔的面分别为顶面和底面,则使多孔那面为底面,即定位基准面。以基准面上的直径为 的两孔以及基准面定位。

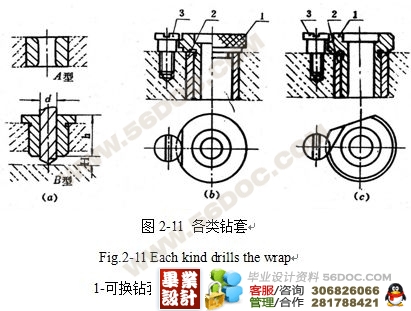

钻模板应垂直与定位基准面,钻套中心线与待加工孔中心线同轴。夹紧件由工件顶面向定位基准面夹紧。采用螺旋夹紧机构。

夹紧机构的选择及设计

从前面提到的夹紧装置组成中可以看出,不论采用何种力源(手动或机动)形式,一切外加的作用力要转化为夹紧力均需通过夹紧机构。因此,夹紧机构是夹紧装置中的一个很重要的组成部分。

夹紧机构可分为斜楔夹紧机构、螺旋夹紧机构、偏心夹紧机构、定心对中夹紧机构等。斜楔夹紧机构中最基本的形式之一,螺旋夹紧机构 、偏心夹紧机构及定心对中夹紧机构等都是斜楔夹紧机构的变型。

斜楔夹紧机构主要是利用其斜楔面移动时所产生的压力来夹紧工件的,亦即一般所谓的楔紧作用。斜楔的斜度一般为1:10,其斜度的大小主要是根据满足斜楔的自锁条件来确定。

一般对夹具的夹紧机构,都要求具有自锁性能。所谓自锁,也就是当外加的作用力Q一旦消失或撤除后,夹紧机构在纯摩擦力的作用下,仍应保持其处于夹紧状态而不松开。

螺旋夹紧机构中所用的螺旋,实际上相当于把斜楔绕在圆柱体上因它的夹紧作用原理与斜楔时一样的。不过这里是通过转动螺旋,使绕在圆柱体上的斜楔高度发生变化来夹紧工件的。

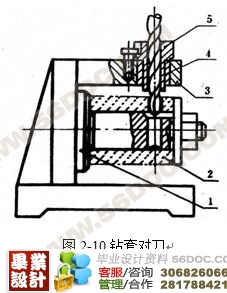

根据齿轮泵壳体的结构特点和对齿轮泵在机床上的位置要求分析,选择了可行的定位方案。同时根据加工回油孔时泵体所处的位置,并通过计算夹紧力来选定了夹紧机构。在钻孔时,用于对刀导引的装置为钻套。根据实际加工情况的需要,决定采用长型快换钻套。最后把夹具体的结构确定下来,并选择夹具在机床上的定位方式。

技术经济性分析

对本次的技术经济性分析,应从以下几方面进行考虑:

1) 从影响成本的各个因素综合考虑 :考虑的回油孔是深孔,但采用深孔加工机床来加工成本太高,所以一般情况下,生产齿轮泵的企业,会选择普通的立式钻床、台式钻床或摇臂钻床来加工齿轮泵壳体的回油孔。并不能满足回油孔加工的条件。另外,普通的钻床由于考虑到一机多用,为满足多种加工要求,采用了多级变速的传动结构。而对于采用流水线式的加工方式来加工的情况来说 ,采用普通机床就是进行了不必要的投资,同时也闲置了普通机床一机多用的功能。由此来看,设计加工回油孔的专机,不仅降低了成本,还能够满足加工的需要。

2) 从设计、生产周期的长短考虑:由于现今机床的生产已成规模,并且机械传动和夹具设计方法也已成熟。设计新型的机床,需要考虑可加工同类或相似的工件来设计,这样就需要根据长时间经验的积累和创新能力来完成,需要的设计周期也长。而本次设计的专用机床只需满足加工回油孔的需要即可,因此设计周期就大大的缩短了。对于加工回油孔,采用专用机床和夹具更能节省时间,提高生产效率。

由此可见,设计齿轮泵壳体回油孔加工专机和夹具的可行性极大,对于降低资金的投入、提高生产效率有很大的帮助。

|