槽形托辊带式输送机设计☆(含任务书,开题报告,论文说明书25000字,外文翻译,cad图纸)

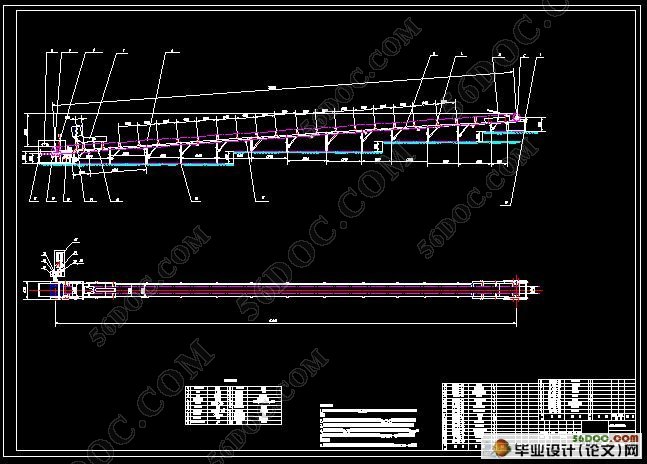

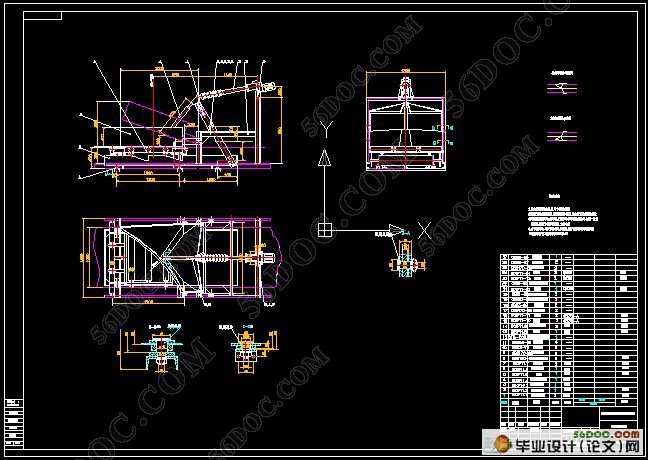

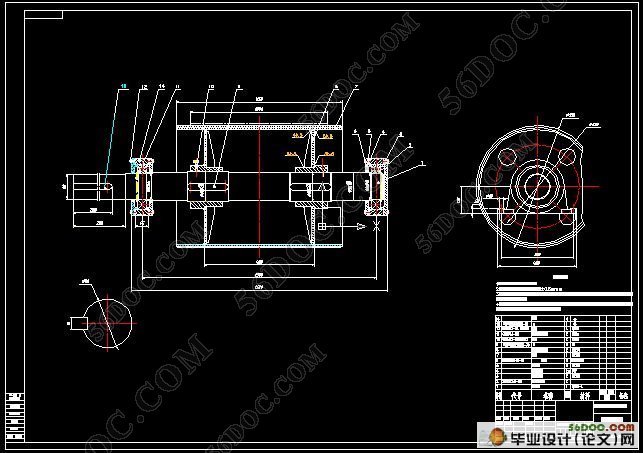

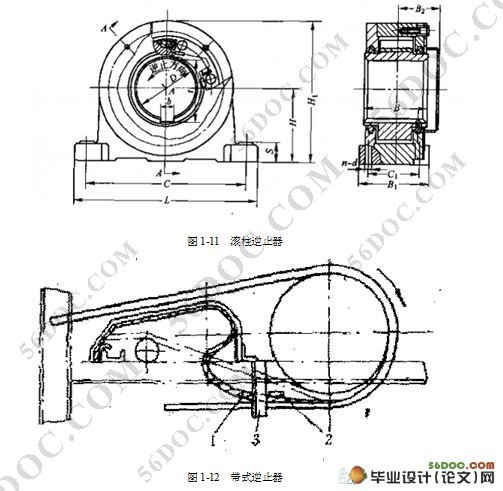

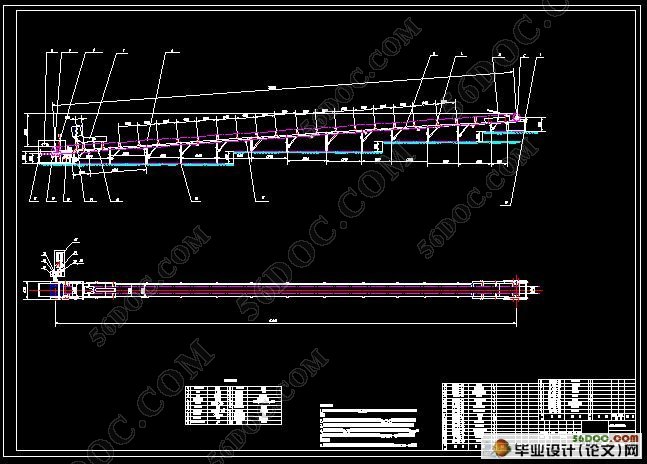

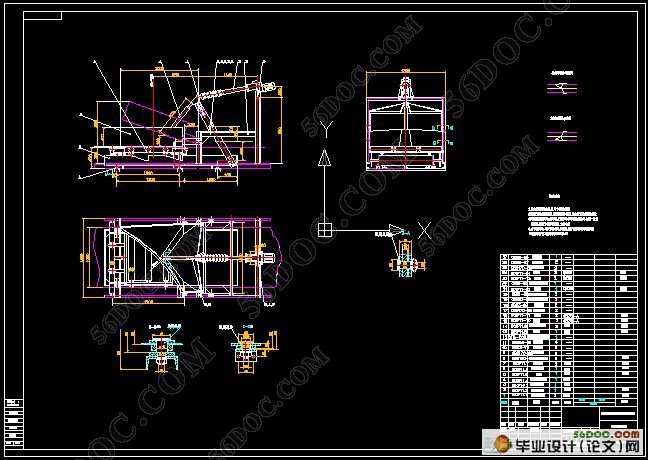

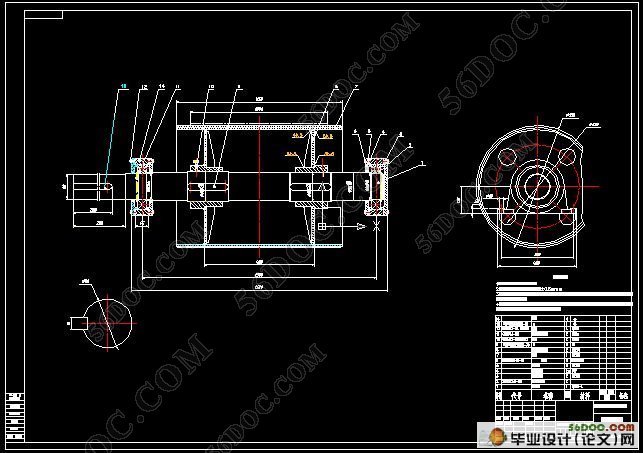

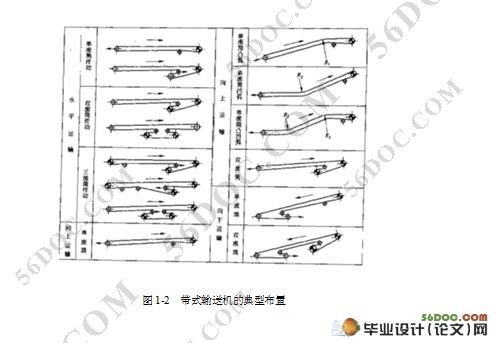

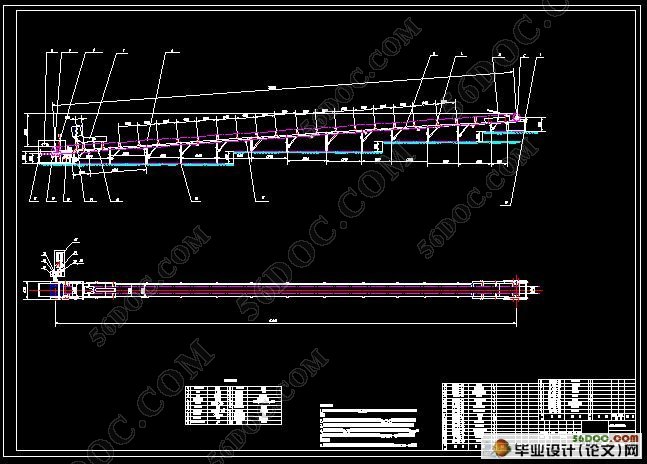

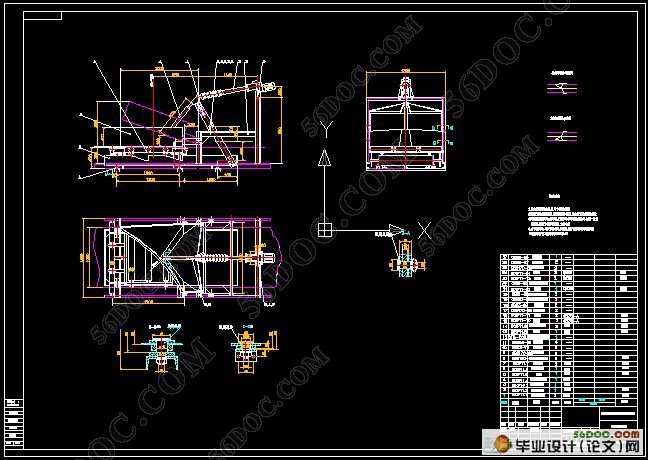

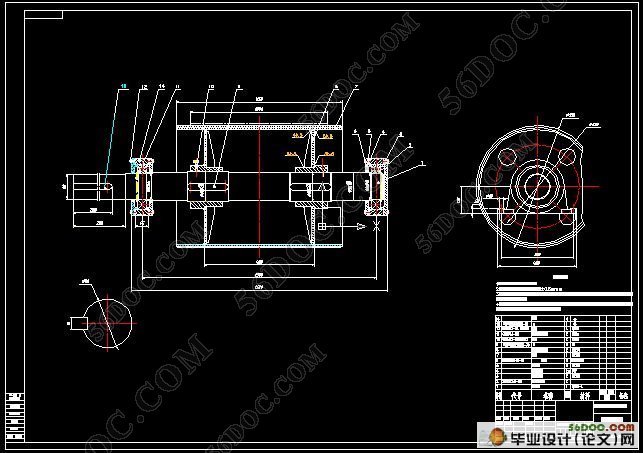

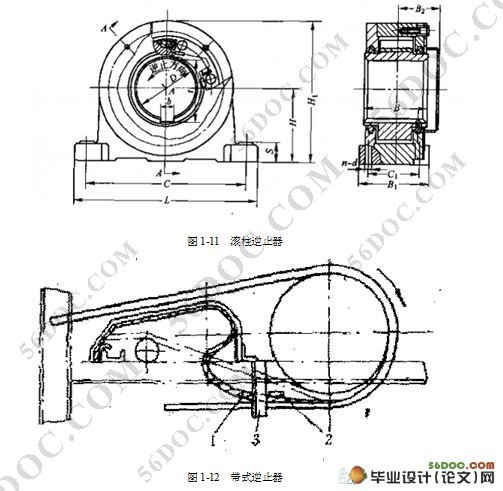

摘要:本文所设计的是槽形托辊带式输送机,其设计要求为:输送物料为原煤,输送量:500吨/小时,输送长度:30 米,提升高度2.5米;堆积密度:900公斤/米3;物料在带面上的动堆积角为300,输送带速: 2米/秒,上托辊槽形布置。设计中,其整体是一个倾斜的状态,上托辊都采用槽形布置;下(回程)托辊采用平行托辊。本输送机为向上运输物料,其倾斜角为3.80<150,所以采用小倾角设计。在设计带宽时,按照槽形布置来选择计算。在尾架的选取方面,采用螺旋拉紧装置尾架,使输送带能始终保持必要的张力。用Solidworks对连接轴进行有限元分析,得出其一般工作时的性能状态,并做出相应的调整。

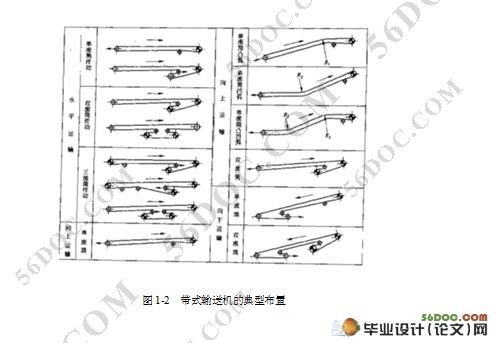

目前,带式输送机正朝着长距离,高速度,低摩擦的方向发展,近年来出现的气垫式带式输送机就是其中的一个。在带式输送机的设计、制造以及应用方面,目前我国与国外先进水平相比仍有较大差距,国内在设计制造带式输送机过程中存在着很多不足。

关键词: 槽形托辊 带式输送机 输送带 有限元分析

The Design of Slotted Roller Belt Conveyor

Abstract: What is designed in this paper is slotted roller belt conveyor, the design requirements are: transport of materials: coal, transport capacity: 450 tons / hour, transmission length: 25 meters, 2 meters high upgrade; Bulk Density: 900 kg / m 3; materials in the dynamic accumulation of the surface with angle is 40, conveyor speed: 1.2 m / s, on the trough roller arrangement. Design of a tilt the overall state of the idler trough arrangement used; under the (return) the use of parallel idler rollers. When the materials are transport up through the conveyor, the tilt angle is 3.80 <150, so take the use of small-angle design. As the selection of the tailstock, we take the use of Tailstock screw tensioning device so that the conveyor system can always maintain the necessary tension. And Solidworks is used to do the finite element analysis on the connecting axis, to meet the required strength.

Today, long distance, high speed, low friction is the direction of belt conveyor’s development. Air cushion belt conveyor is one of them. At present, we still fall far short of abroad advanced technology in design, manufacture and using. There are a lot of wastes in the design of belt conveyor.

Keywords: slotted roller belt conveyor conveyor idlers Finite Element Analysis

毕 业设计(论文)使用的原始资料(数据)及设计技术要求:

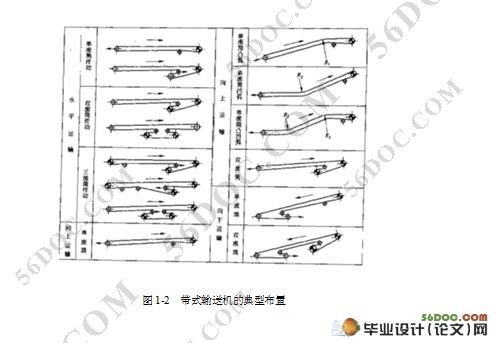

带式输送机是一种摩擦驱动以连续方式运输物料的机械。应用它,可以将物料在一定的输送线上,从最初的供料点到最终的卸料点间形成一种物料的输送流程。本输送机用于碎散物料的上行输送。

1. 输送长度:30米,提升高度2.5米;

2. 输送量:500 吨/小时, 输送物料为原煤;

3. 堆积密度:900公斤/米3;物料在带面上的动堆积角为300;

4、输送带速:2米/秒

|