气流输送系统的设计(含任务书,开题报告,论文说明书19000字,外文翻译,cad图纸)

摘要:气流输送技术是一项综合技术,涉及流体力学、材料力学、自动化技术、制造技术等领域,属高新技术项目。气流输送的应用已有100多年的历史,早在1853年邮局就用来输送信件,1883 年港口用于装卸粮食,到20 世纪初开始用于工业生产。近年来,随着生产发展和生产过程日趋自动化,对节约能源和环境保护的要求越来越高,气流输送技术凭借自身的技术特点得到了迅速发展和应用。在不断地探索和创新过程中,气流输送的对象从早期的谷物,面粉和信件迅速扩展到水泥,砂料,化工原料,煤粉等物料。应用的范围遍及粮食,港口,化工,冶金,电力,铸造,食品,医药等领域。输送方式从原始到如今完善,合理,从稀相悬浮输送到浓相浓度的栓流输送,初步解决了气流输送能耗高,管道磨损及物料破碎等问题,提高了气流输送技术的可靠性和经济性。

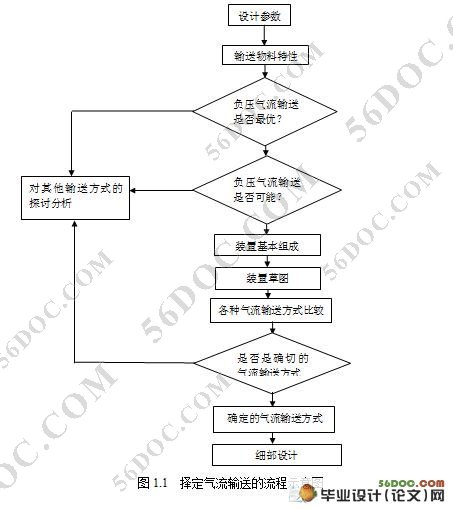

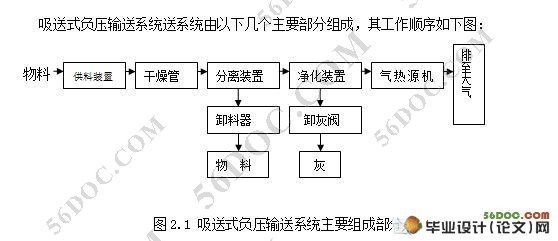

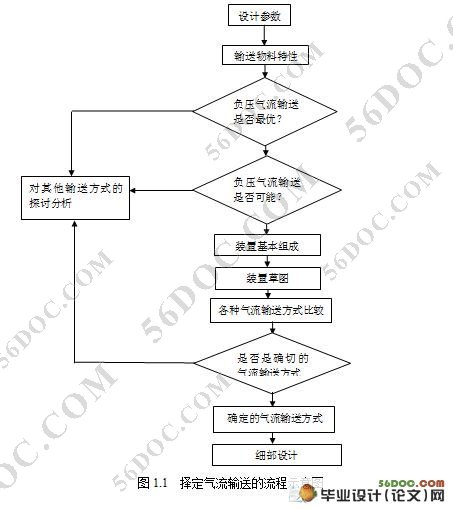

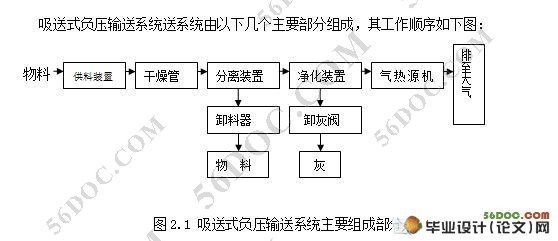

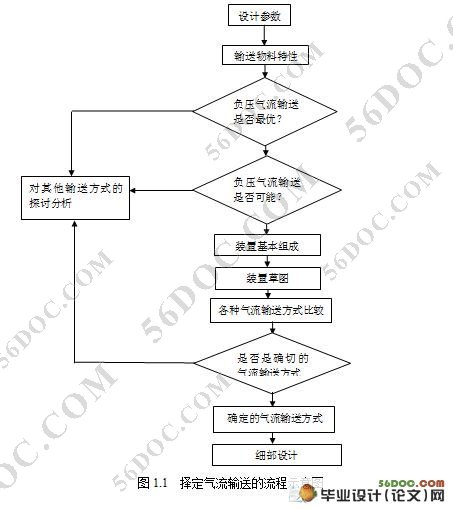

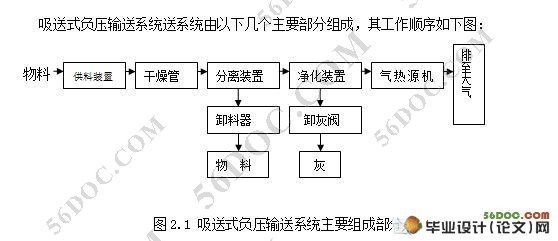

本文通过对原始材料的分析,采用了吸送式气流输送。吸送式气流输送装置在气流输送技术中是一种较早发展起来的输送方式,目前在世界上使用十分广泛,这是因为它除了具有广泛适应条件外还有许多突出的优点:生产率高,结构简单紧凑,操作灵活方便易实现自动化等。

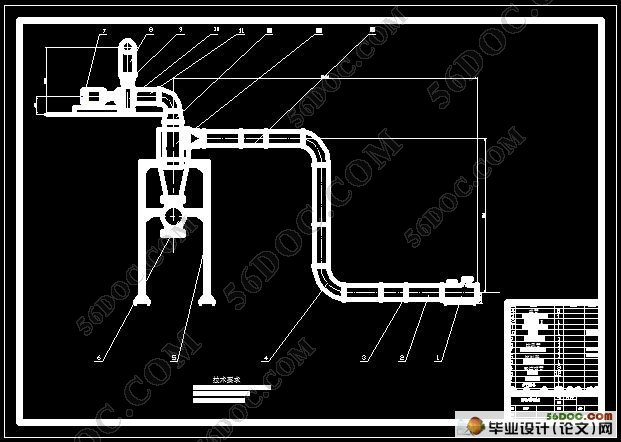

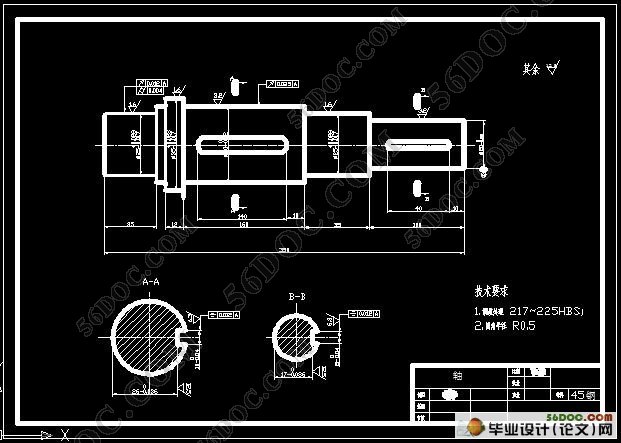

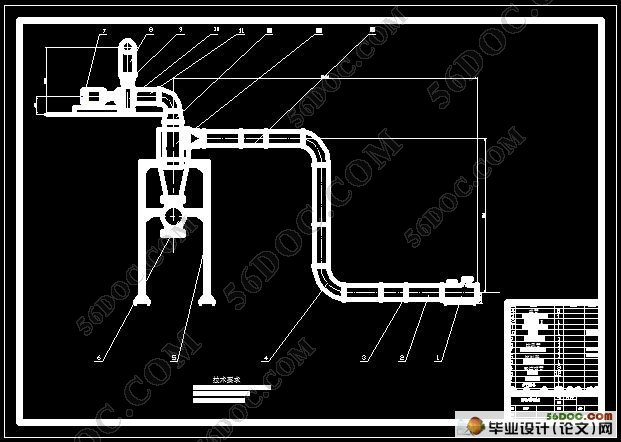

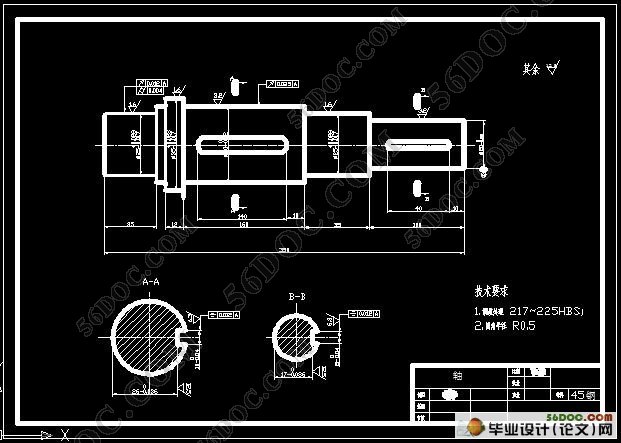

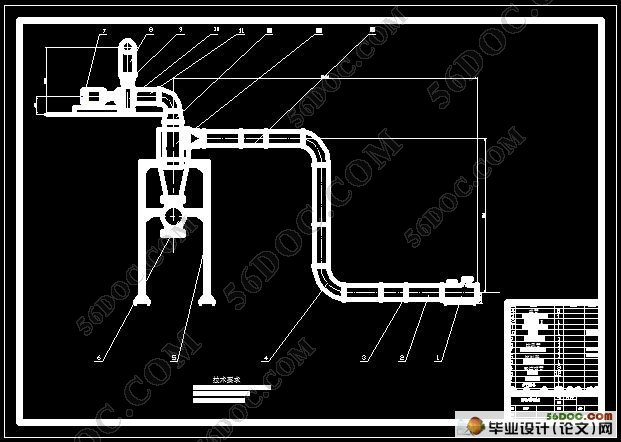

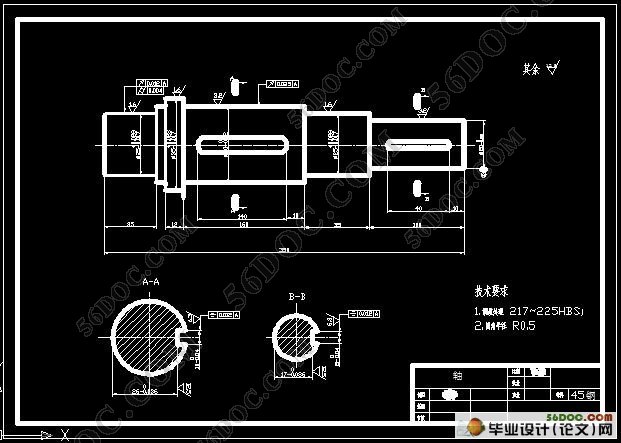

根据其原始材料,计算其输料管内径,确定输送风速及其风量,同时要计算系统中各项的压力损失。在这些都确定的情况下,根据上述分析计算结果选定适合的风机及其配备电动机,确定确实合理的管道布置方式,最后得出整套输送装置。

关键词: 吸送式气流输送 输料管内径 压力损失

Pneumatic Conveying System

Abstract: Pneumatic Conveying technology is a comprehensive technical, involving fluid dynamics, mechanics of materials, automation technology, manufacturing technology and other fields,which belongs to a high-tech projects. The application of Pneumatic Conveying has been more than 100 years of history, back in 1853, the post office had used it to deliver correspondence;in 1883 the port for loading and unloading of foodstuffs, to the beginning of the 20th century for industrial production.In recent years, with the development of production and the production process automation, energy conservation and environmental protection in an increasingly high demand., pneumatic conveying technology, by virtue of its technical characteristics have enjoyed rapid development and application. In the process of exploring and innovation constantly, the object of pneumatic conveying changes from the early cereals, flour and letters to the rapid expansion of cement, sand and industrial chemicals, coaldust and other materials. Application areas include of food, ports chemical engineering, metallurgy, power, casting, food, medicine and other fields; Transportation mode perfects from the original to the present perfection, reasonable, from dilute phase suspension transported to Ph indicator bolt flow conveying of dense phase, preliminarily settling of the problem of pneumatic conveying of high energy consumption,pipeline of high wear and tear and materials broken, which improve the reliability of the technology and economy of the pneumatic conveying.

Based on the analysis of the original material, this thesis adopts the use of suction sent pneumatic conveyor. Suction sent pneumatic conveyor installations is a development for the early delivery in the gas-delivery technology; Now to be used in a very wide range in the world, it is in that in addition to its extensive adaptation conditions, there are still many outstanding advantages : high productivity, simple and compact structure, flexible and user-friendly operation to achieve automation.

Baed on its original material, the writer has to calculate internal diameter of the conveying pipe, determine wind speed and wind transport volume, also has to calculate the various system pressure loss. In the case of these being identified, the writer ,according to the above analysis and computing results , is to selected the suitable Fan and its equip motor, determine the exact piping layout in a reasonable way, and get the final package delivery devices.

Keyword: Suction sent Pneumatic Conveying Send conveying pipe internal diameter Pressure loss

毕业设计(论文)使用的原始资料(数据)及设计技术要求:

1.输送量:10吨/时;

2.物料:小麦;

3.输送距离:30米;

4.空气(动力)设备:罗茨鼓风机;

5.功率:11千瓦;

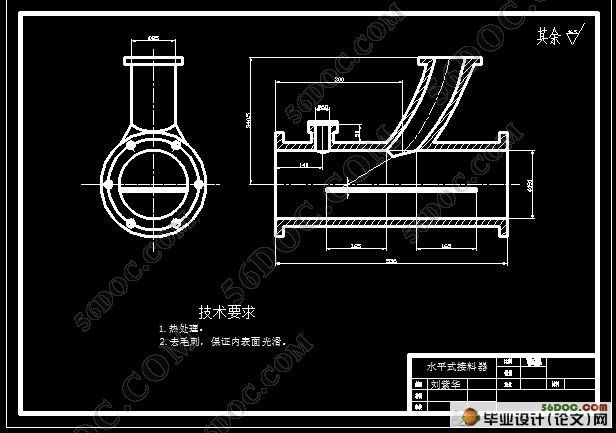

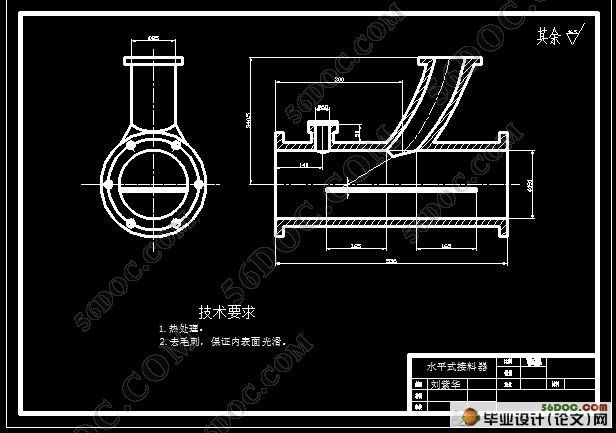

6.卸料方式:离心卸料;

7.输送管道采用普通碳钢材料。

设计的原始条件

1.输送物料:淀粉;

2.处理量:0.5吨/小时;

3.淀粉初含水率:≤40%;

4.淀粉终含水率:≤14%;

5.系统动力:≤40KW;

6.单位蒸汽消耗量:≤2.0kg汽/kg水。

|