混凝土搅拌机机械部分设计(含cad零件图,装配图)(含选题审批表,任务书,开题报告,中期检查表,论文说明书16000字,CAD图纸10张)

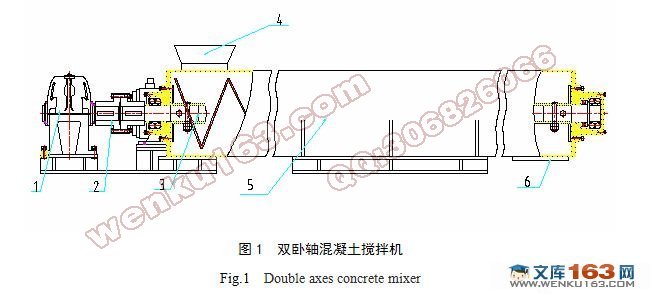

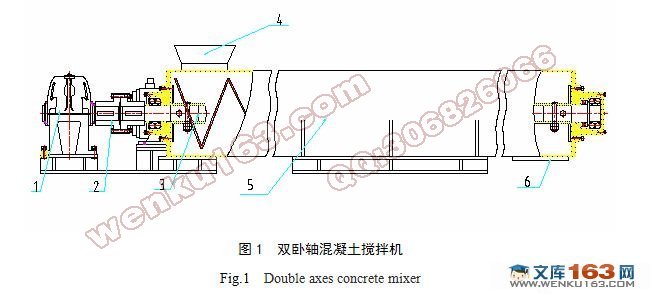

摘 要:混凝土搅拌机是施工机械装备中的重要设备,其产品质量和生产效率直接影响着建筑施工质量和建筑施工进度。强制式搅拌机是应用最普遍、使用率最高的混凝土搅拌机。双卧轴搅拌机是新型搅拌机型,因其搅拌质量好,生产率高,被广泛用于各种搅拌场合。本毕业设计从搅拌的目的和机理出发。工作时,物料在叶片推动下沿螺旋面移动,由于两轴的旋转方向相反,两轴间的物料产生挤压、翻滚和揉搓,以达到搅拌混合效果。通过对卧轴式搅拌机的叶片结构和曲面形状进行合理的布置和设计,混凝土的质量和生产效率会有很大的提高。

关键词:混凝土搅拌机;双卧轴; 叶片

Design of Double Horizontal Concrete Mixer’s Mechanical Parts

Abstract:Concrete mixer is the key device of construction machinery and equipment. It has product quality and production efficiency, which directly impacts on the construction quality and progress of construction. Compulsory mixer is the most common and the highest utilization rate of concrete mixers.Double horizontal shaft mixer is a new-style mixer, which is widely used in many conditions because of the high mixing quality and productivity.This paper begins with the mechanism and purpose of mixing. The materials leaves along the spiral of mobile on the work. Because of the two axis of rotation opposite direction, the materials between the two axis produces extrusion rolling and scrubbing, in order to meet the stirring mixed effect. It has been proved in the long-term production, through the horizontal Coaxial mixer surface of the leaf structure and shape of a reasonable layout and design, concrete’s quality and production efficiency will be greatly improved.

Key words: concrete mixer; double horizontal ;shaft

目 录

摘要…………………………………………………………………………………1

关键词………………………………………………………………………………1

1前言…………………………………………………………………………………2

2总述…………………………………………………………………………………2

2.1 搅拌的作用………………………………………………………………2

2.1.1 混凝土的组成……………………………………………………2

2.1.2 搅拌的任务………………………………………………………3

2.1.3合理的搅拌机理……………………………………………………3

2.2 混凝土搅拌机的类型…………………………………………………4

2.3 国内外混凝土搅拌机的发展状况………………………………………5

3 总体设计方案确定及动力元件选择……………………………………………5

3.1 总体设计…………………………………………………………………5

3.2 混凝土搅拌机的工作原理………………………………………………9

3.3 电动机的选型……………………………………………………………6

3.4 减速器的选型……………………………………………………………6

3.5 联轴器的选择与计算……………………………………………………7

4 搅拌系统的设计与计算………………………………………………………8

4.1 总体方案的拟定…………………………………………………………8

4.2 方案的分析和确定………………………………………………………9

4.3叶片主要参数的设计……………………………………………………11

4.4 主轴转速的确定…………………………………………………………12

4.5 螺旋叶片的加工…………………………………………………………13

4.5.1 叶片螺旋面的成形………………………………………………14

4.5.2坯料形状的选择…………………………………………………14

4.5.3 整圆坯料尺寸的确定……………………………………………14

4.5.4 压模主要尺寸的确定……………………………………………14

4.6 螺旋叶片的校核…………………………………………………………16

5筒体和搅拌轴的简要设计………………………………………………………21

5.1 筒体的主要参数…………………………………………………………21

5.2 搅拌轴的主要参数………………………………………………………21

6轴的设计与计算…………………………………………………………………22

6.1左轴的校核………………………………………………………………22

6.1.1 初步估算轴的直径………………………………………………22

6.1.2 轴的结构设计……………………………………………………22

6.1.3 轴承的校核……………………………………………………23

6.1.4轴的校核…………………………………………………………25

6.2 键的校核…………………………………………………………………26

6.3 销轴的校核………………………………………………………………26

6.4 右轴的校核………………………………………………………………27

6.4.1初步估算轴的直径………………………………………………27

6.4.2 轴的结构设计……………………………………………………27

6.4.3 轴的强度校核……………………………………………………28

6.4.4 轴承的校核………………………………………………………29

6.5 搅拌轴套筒的校核……………………………………………………30

7结论………………………………………………………………………………31

参考文献……………………………………………………………………………31

致谢…………………………………………………………………………………33

|