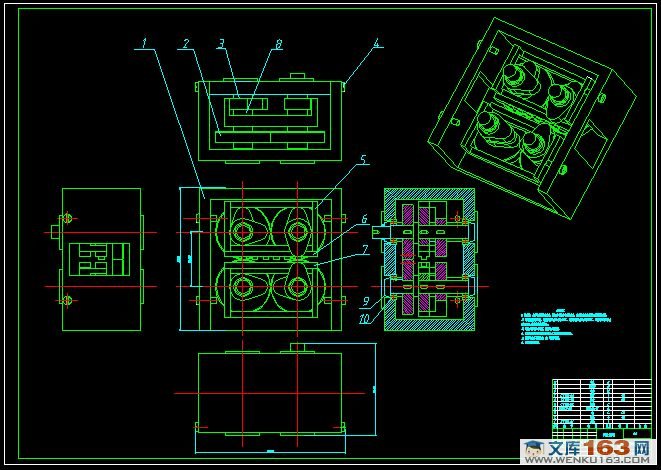

高速平动冲压装置的设计方法及装置设计(含任务书,开题报告,外文翻译,毕业论文说明书19000字,CAD图纸8张)

摘 要

创新教育是加速培养创造性人才的重要手段和方法,是素质教育的一个重要组成部分,是把创新学、发明学、基础知识等相关学科的一般原理有机综合起来,培养学生的创新思维和提高创新能力的一个重要过程。高速冲压技术是集设备、模具、材料和工艺等多种技术于一体的高新技术。相对于普通冲压而言,高速冲压的速度每分钟在几百次到上千次,因此其生产效率要高出普通冲压上十倍甚至几十倍,被誉为是一种质量好、效率高、适合于大规模生产、成本低的先进制造技术,在电子、电器、汽车家电等工业领域的应用越来越广泛,如电子接插件、电器接插件、各类连接器、IC框架、汽车连接件、空调器散热片、医疗器件等一些中小型及微细金属零件及超微细金属零件均可实现高速冲压。高速冲压技术是集设备、模具、材料和工艺等多种技术于一体的高新技术。主要表现为:实现高速冲压的设备不但本身具有高的加工精度和全自动化数字化功能,其配套的周边设备、模具的结构设计、材料选用等均需考虑由于高速条件下温度、振动等效应带来的影响;工艺设计时的排样和出料、定位和导料等都必须考虑速度因素。这些也是高速冲压需要达到高生产率、获得高精度零件,并保证模具和设备的使用寿命长、制品的材料利用率高的关键技术。高速冲压技术是近20年发展起来的先进成形加工技术,20世纪80年代末开始在我国的一些外资企业应用,当初其设备和模具均是依靠进口。最近10年来我国在高速冲压技术方面从引进、消化吸收到自主开发都有了较快的发展,有了自主开发的高速压力机、高速冲压用模具材料、可自行设计和加工高速冲压用多工位级进模具等。但是其水平与发达国家相比还有较大的差距。如何缩小与发达国家的差距,加快我国高速冲压技术的推广。

关键词:创新;功能元;高速冲压

Abstract

Innovative education is important to accelerate training creative talent means and methods, quality education is an important component of the innovation and science, inventions science, basic knowledge of related disciplines such as general principles of organic synthesis up to train students in creative thinking and improve the innovation ability of an important process. Using functional element for the Creative Design.Technology is a high-speed stamping equipment, tooling, materials and technology and other technologies in one high-tech. Compared with the general press, the rate of high-speed stamping hundreds of times per minute to thousands of times, so its efficiency is higher than normal times or even dozens of times on the press, hailed as a good quality, high efficiency suitable for mass production, low cost, advanced manufacturing technology, electronics, appliances, automobiles and home appliances industry is widely applied, such as electronic connectors, electrical connectors, various connectors, IC frame, car connection parts, air conditioner heat sink, medical devices and some small, medium and micro metal parts and metal parts can be ultra-fine high-speed stamping. Technology is a high-speed stamping equipment, tooling, materials and technology and other technologies in one high-tech. Mainly as follows: high-speed stamping equipment for not only its high precision and fully automated processing of digital features, its supporting peripheral equipment, die structure design, material selection, and must be subject to conditions as high temperature, vibration and other effects caused impact; process design the layout and the materials, positioning and guidance material and so the speed factor to be considered. These are also high-speed pressing need to achieve high productivity, access to high-precision parts and tooling and equipment to ensure long life products, high utilization ratio of key technologies. High-speed stamping technology in the last 20 years developed advanced forming technology since the late 80s of the 20th century a number of foreign applications in China, had their equipment and molds are imported. The last 10 years in China in the high-speed press technology from the introduction, digestion and absorption to have developed a rapid development, with self-developed high-speed presses, high-speed press with a mold material can be designed and processed with multiple high-speed stamping the Progressive molds. But the level of developed countries there is a large gap. How to narrow the gap with the developed countries to speed up our high-speed press technology promotion and application of engineering and technical personnel is stamping industry incumbent.

Keywords: innovation; functional element; high-speed stamping

科学依据

工程问题:同步高速冲压。板厚1mm,孔长4.5mm,孔宽1.5mm,孔距2mm,板以50M/m直线匀速。要求工作平稳,噪音小。冲压时工件与冲压机构同步横向运动。

创新教育是加速培养创造性人才的重要手段和方法,是素质教育的一个重要组成部分,是把创新学、发明学、基础知识等相关学科的一般原理有机综合起来,培养学生的创新思维和提高创新能力的一个重要过程。

可根据世界现有水平进行构造全新的新机构或者对已知机构进行变性创新。

研究内容

1.制定机械产品方案设计(功能元分析方法)模式、功能元、形态矩阵的建立。

2.方案评价、确定

3.同步高速冲压机构的设计(机构运动简图、运动特性分析、结构设计、主要零部件的设计计算和强度校核

目 录

摘 要 III

Abstract IV

目录 V

1 绪论 1

1.1 课题背景 1

1.2 课题的研究意义 1

1.3 本文研究的主要内容和关键问题 2

1.4 功能分析法 2

1.5用功能分析法确定设计方案..............5

2 总体设计................................................... 7

2.1 方案设计................................7

2.2 功率计算及电动机的选择 8

3技术计算与设计 8

3.1 传动齿轮的计算 11

3.3 轴的计算与设计 .15

3.4 滚动轴承的选择及校核计算 17

3.5 凸轮的计算与设计 19

3.6 键联接的选择及校核计算 20

3.7 润滑与密封 20

4 齿轮加工工艺 21

4.1 直齿圆柱齿轮的主要技术要求 21

4.2 直齿圆柱机械加工的主要工艺问题 22

4.3 实施装置中的齿轮.............................................25

5 三维图的绘制 25

5.1 三维图绘制方案的确定 25

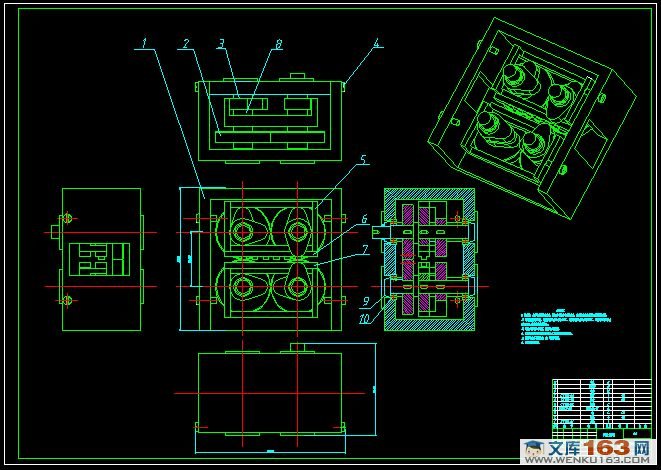

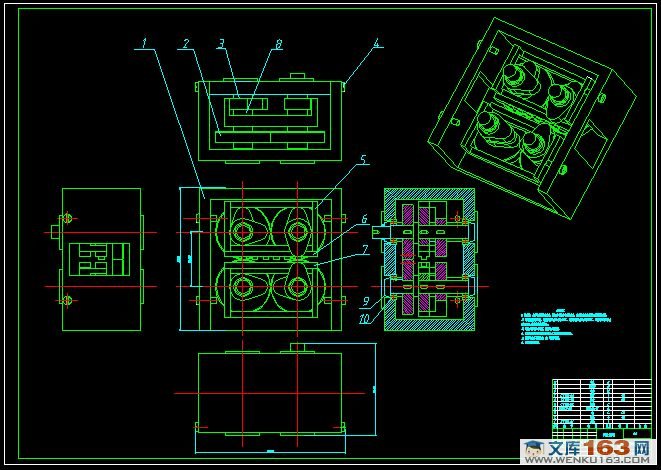

5.2 三维图的图样 26

6 设计的不足以及展望...................30

致谢 32

参考文献......................33

|