箱式电炉进出料机设计(含cad图纸)(任务书,开题报告,外文翻译,毕业论文说明书13000字,进度检查表,CAD图纸4张)

摘 要

75kW和95kW箱式电炉是热处理专业厂及一般中型机械厂目前最常使用的热处理加热设备。过去传统的装出炉方法都是操作,采用手工将工件送入炉膛热处理后再由炉内取出。由于箱式电炉炉膛深,且工件只能在水平方向进出炉门,小工件随手甩进,大工件抬至路口用撬棒等推入炉门,劳动强度很大。为此,我们在毕业设计前提出了有关该课题的设计,该机使用于批量生产的机械零件热处理加热时的进出料,特别适用于RJX-75-9和RJX-95-9型等炉膛较深的箱式电炉加热大件时的进出料,也可用于炉膛尺寸与上述箱式电炉相近的燃料炉。经系列化后也可用于其他型号的箱式炉。箱式电炉进出料机的整机外形为一密封型小车,由电器控制系统、行走动力系统、推拉传动系统、推拉机构、机架、电磁止退系统等部分组成,此外还配有配套件地面导轨、炉内导轨及燃料等。其中电器控制部件全部装在小车体内,仅有控制按钮盒在体外作远距离控制之用。

关键词:箱式电炉;进出料机;推拉机构

ABSTRACT

75 and 95 dyadic kw box electric furnaces are that the heat treatment that the heat treatment special field factory and in general medium-sized machinery works use at present most often processes equipment. That tradition dress going over puts up stove method all is to adopt manual operation , the inner takes out again from the stove after sending workpiece in furnace chamber heat treatment. The electric furnace furnace chamber is deep since the box is dyadic , workpiece can only pass in and out of a furnace gate in level direction and , minor workpiece is flung handily moving forward, big workpiece raise till the crossing uses crowbar to wait to push entering a furnace gate, labor intensity is very big. For this purpose, we have brought forward design about that problem in graduation practice prelude , the turnover that machine uses when heat treatment heats in the machinery parts mass-producing has expected that , the turnover applying to electric furnaces of furnace chamber more dyadic than deep box such as RJX-75-9 and RJX-95-9 type specially when heating durable household appliances has expected that, also may be used for close to above-mentioned dyadic box electric furnace furnace chamber dimension fuel stove. In the day after tomorrow the type box is also Yong Yu other dyadic as a result of being seriated stove. Dyadic box electric furnace turnover expects that the machine complete machine external form seals off the type handcart for one, driving force system , push-and-pull drive system , push-and-pull organization , chassis , electromagnetism controlling system , going on foot from electrical equipment stop returning system waiting for part made up of, besides be qualified for have parts and auxiliary equipment floor slide way , stove inner slide way and fuel etc.All dress of electrical equipment function units among them experiences and observes an inner in the handcart , has the under the control of button box to control that in extracorporeal distant work distance using only.

Keywords: Dyadic electric furnace of box; Machine passing in and out of material; Push-and-pull organization

2 设计方案的确定

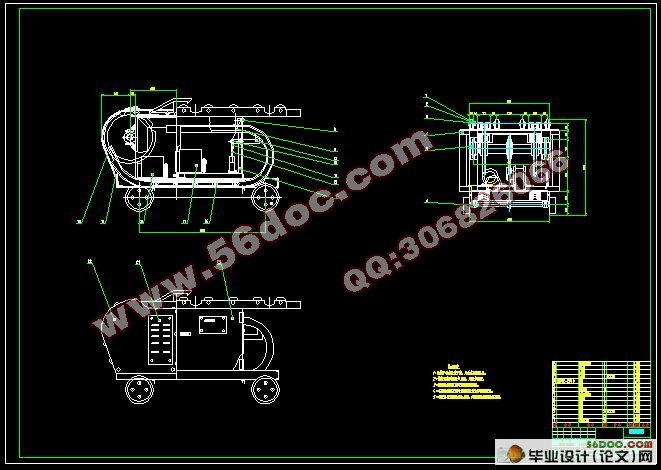

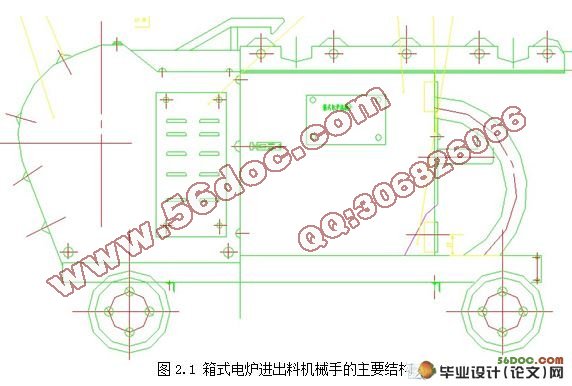

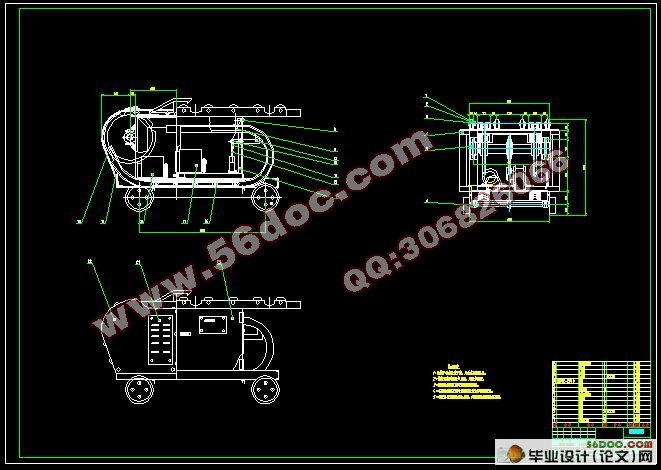

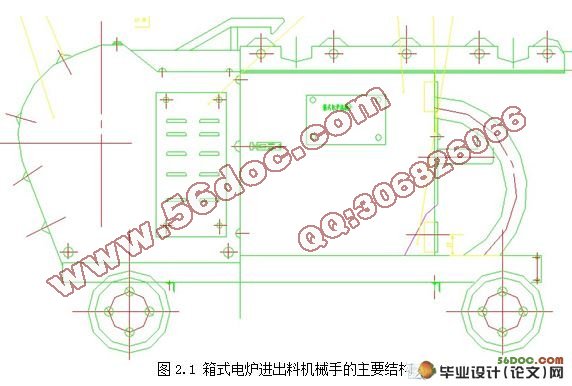

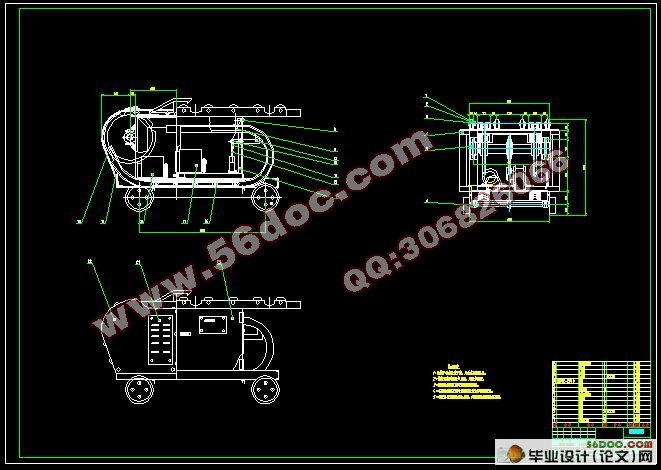

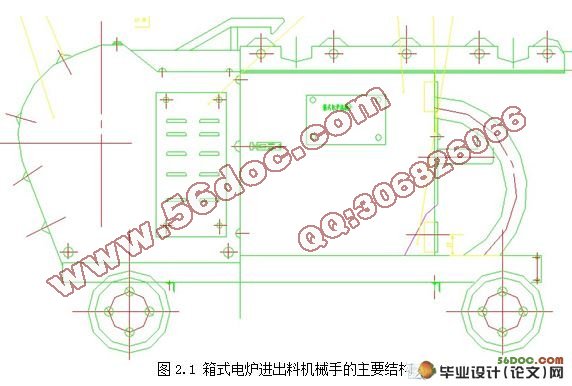

2.1 主要结构【1】

箱式电炉进出料机械手的主要结构如图2.1所示。它整机外型为一密封型小车,由电器控制系统、行走动力系统、推拉传动系统、推拉机构、机架、电磁止退系统六部分组成。此外还配有配套的地面铁轨、炉内导轨及燃料等。其中,电器控制组件全部装在小车体内,仅有控制按钮盒在体外作远距离 控制之用。

2.2 工作过程

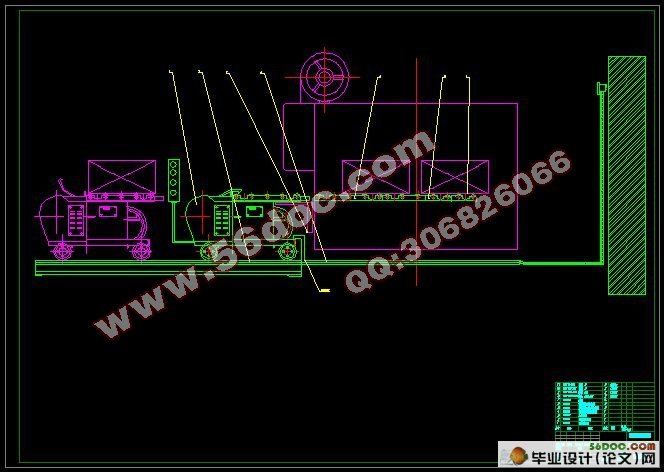

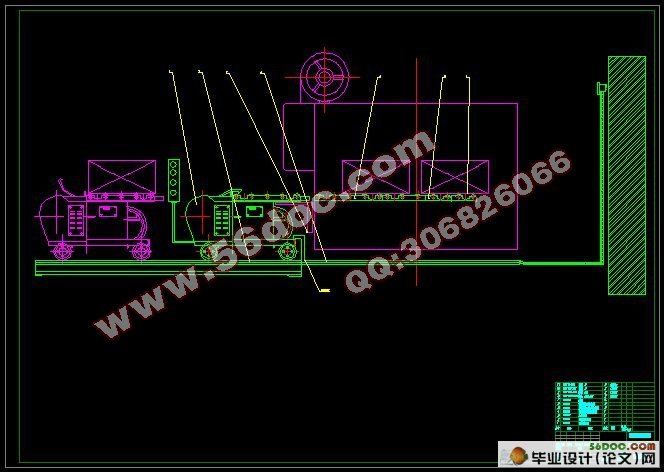

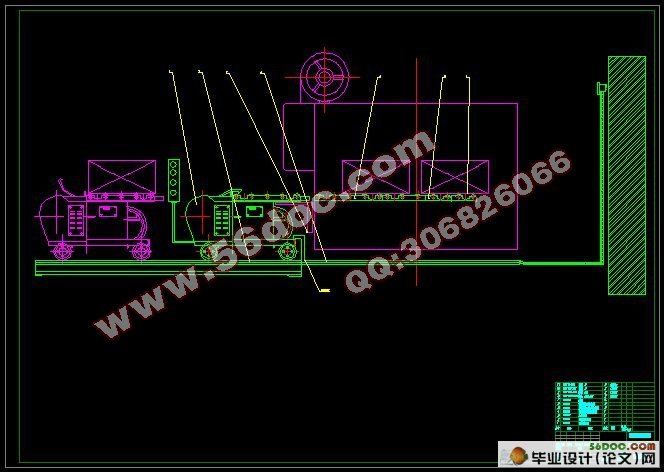

将进出料机械手平稳地放在用混凝土浇筑的地面铁轨上,炉内导轨安放在炉底板上,通过行走传动系统传动,进出料机械手在铁轨上作前进和后退运动,即可驱使远离炉门;装料时,驶近炉门使机上导轨与炉内导轨接拢,同时,电磁止退系统动作,止退钩钩住炉体,防止向炉膛推送料板时机体的后移;通过推拉传动系统传动,推料头可预先装好工件的料板推进炉膛;出料时,则由拉料钩从炉膛拉出料板及已加工完成的工件,到位后拉料钩自动弹出,用其中设备掉走料板和工件,经两次推拉聊过程即可完成一个装料周期。

2.3 主要性能指标

工作方向:双向推拉;

最大推拉料行程:2.2m;

推拉料速度:145mm/s;

最大行走距离:2m;

行走速度:150mm/s;

一次最大装料量:1200kg;

最高适合炉温:950oC;

消耗功率:1.3kW,其中行走电机0.55kW,推拉电机0.75kW;

外形尺寸:1816×890×880mm;

整体重量:500kg。

目 录

摘 要 III

ABSTRACT IV

目录...............V

1 绪论 1

2 设计方案的确定 3

2.1 主要结构【1】 3

2.2 工作过程 3

2.3 主要性能指标 3

3 传动机构的设计与计算 5

3.1 锥齿轮的设计[1] [2] [3] [4] [5] [7] [9] 5

3.2 锥齿轮轴的设计 8

3.2.1 轴上零件的固定[1] [2] [3] [8] [12] 8

3.2.2 花键的设计[1] [2] [3] [12] 9

3.2.3 轴承的选择[1] [2] [3] [4] [8] [10] [12] 9

3.2.4 轴的强度计算 [2] [3] 11

3.2.5 轴的刚度计算[2] [3] 13

3.3 传动轴的设计 13

3.3.1 轴上零件的固定[11] [14] 13

3.3.2 花键的校核[4] 13

3.3.3 轴承的校核[4] 13

3.3.4 轴的强度计算[2] [3] 15

3.3.5 轴的刚度计算[2] [3] 17

3.4 减速箱箱体的设计[12] [15] [16] 18

4 行走机构设计与计算 19

4.1 对机构进行受力分析[2] [3] 19

4.2 轮轴和滚轮扭矩的计算[2] [3] 19

4.2.1 后轮轴的尺寸计算[2] [3] 19

4.2.2 后轮轴的强度计算[2] [3] 21

4.2.3 后轮轴座的选择及轴承寿命的校核[4] 24

4.2.4 前轮轴的尺寸计算[2] [3] 25

4.2.5 前轮轴的强度计算[2] [3] 26

4.2.6 前轮轴的选择及轴承寿命的校核【4】 30

4.3 减速机的输出扭矩和输出功率的计算[2] [3] [4] 31

5 推拉机构的设计与计算 32

5.1 链轮和链条的设计 32

5.1.1 链传动的特点[17] [19] 32

5.1.2 链传动的尺寸计算[2] [3] [4] 32

5.2 中间长轴的设计 34

5.2.1 轴上零件的固定[2] [3] [4] [9] [11] 34

5.2.2 花键的校核[4] 34

5.2.3 轴承的选择[2] [3] [4] 34

5.2.4 轴的强度计算[2] [3] 35

5.2.5 轴的刚度计算[2] [3] 37

6 其他部件的校核 38

6.1 连接钢管的选择[1] [7] 38

6.2 钢管弯曲强度校核[2] [3] [4] 38

6.3 螺栓校核[2] [3] [4] [8] [9] 39

7 结论与展望 40

7.1 结论 40

致 谢 41

参考文献 42

|