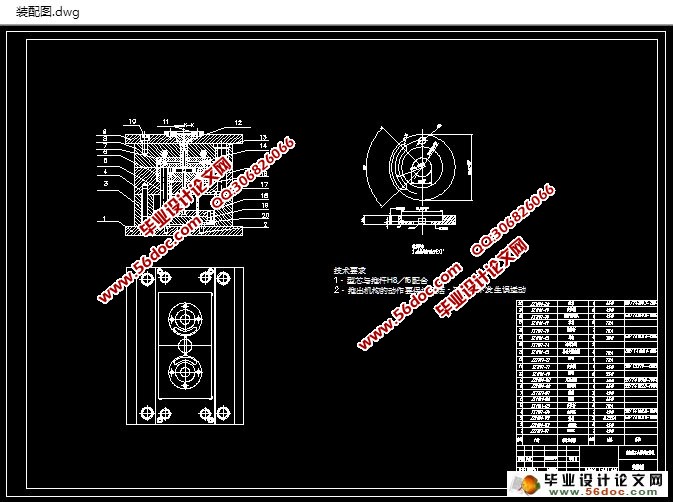

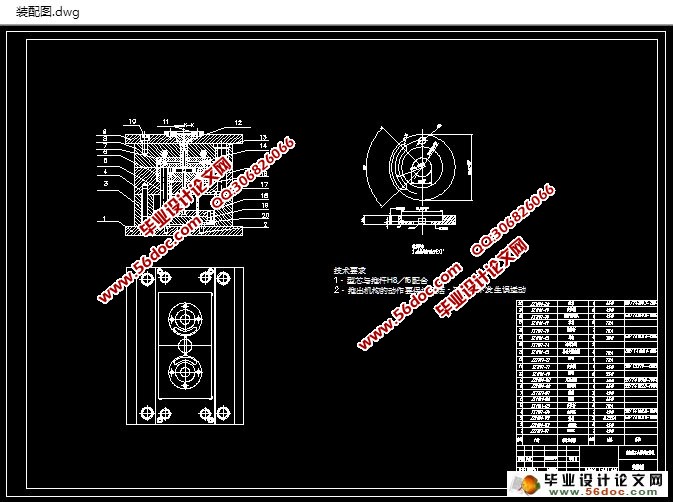

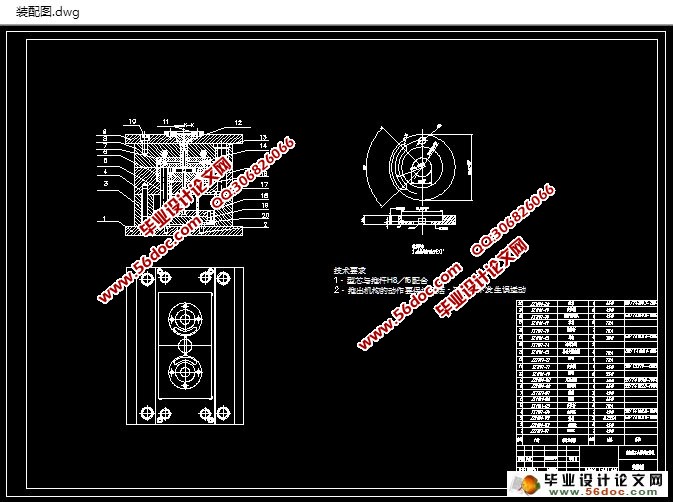

400×350隔弧板注射模具的设计(含CAD零件装配图)(任务书,设计说明书13800字,CAD图纸5张)

摘要

此次我的毕业设计主要是针对于隔弧板注射模具方面的设计,21世纪以来,出于模具技术能力的方面人才越来越优秀和模具行业的发展过于迅速。模具设计与制造已看做一个行业的重要衡量标准,这方面的能力越来越引起人们的重视。作为塑料制造业的顶梁柱——塑料模的设计与制造也相应的得到了很大的升华。

模具产业现已经成为了提升我国国民经济水平的基础工业,是能够在国际上拥有着公认的关键型工业。模具的生产技术方面的能力是能够作为权衡一个国家的产品制造水平实力的主要象征之一,它能在很大的程度上决定着产品的质量好坏,从而间接的影响了产品的效益和新产品的开发能力。

塑料制品方面尤其突出,已经在国防,农业,工业和日常生活,衣食住行,安身立命中的方面得到非常大应用。在电子信息业中则愈加的超绝。很多的电子产品外壳的材料都是用的塑料制品,产品质量与工艺的提高是取决于塑料性能和高品质的塑料模具。

因此,根据本人对一些实际情况的基本了解,从产品结构工艺性,具体的模具结构出发,合理的加工工艺,拟定出模具的基本结构形状,对塑料制品工艺上的改进和质量上的进行分析,以促成自动化提升产量。

对于隔弧板构造的详细形状进行更确切的分析,此模具是一种侧浇口的单分型面注射模具。由于结构的观察发现塑件外侧有一个小孔,所以要设置斜导柱侧抽芯机构的结构形式。这样做的优点在于构造简化,使模具外形进行压缩,以至于减少了制造模具的成本。

毕业设计是总结了我们四年来所学知识的一个体现,我通过进行对其尺寸大小的计算,设计出推出机构、主流道与分流道、冷却水道、模具构架等尺寸,主要利用了UG( Unigraphics)和 Auto CAD(Computer Aided Design)对我设计的产品进行了二维和三维的分析之后绘制总装图和零件图。

关键词: 隔弧板; 注射模具; UG; CAD; 塑料模

Abstract

This topic mainly aimed at the arc plate injection mould design, in recent years, due to the rapid development of the mould technology. Mold design and manufacturing has become an industry more and more cause the attention of people. As a pillar industry of plastic - plastic mold design and manufacturing has been an unprecedented development.

Mould industry is the basic industry of national economy in our country, is the key in the internationally recognized type of industry. Mold production technology level of high and low is the ability to measure a country manufacturing level one of the important marks of the product, it can to a large extent determines the quality of products, thus indirect influence the benefits of the product and new product development capability.

Plastic products in particular, has been in the defense, agriculture, industry and widely used in everyday life. Especially in the electronic information industry is particularly prominent. Most of the electronic product shell plastic products, is the requirement that is depends on the improvement of the performance of the product of high quality plastic mould and plastic properties.

Therefore, according to oneself of some of the actual situation of basic understanding, from the process of product structure, the specific structure of the mold of the reasonable processing technology, draw up the basic structure of the mold shape, to analysis the quality of plastic products and technology improvements, in order to realize the automation to increase production.

According to the specific structure of arc isolation board, the mold is a side gate of the single type of injection mold. Because of the structure of the observed parts of the lateral has a small hole, so to set up the structure of inclined guide pillar side core-pulling mechanism. The advantage lies in the organization to simplify, make the mould shape to narrow, which reduces the mold manufacturing costs.

The graduation design is summarized in an embodiment of our three years of knowledge, I calculated the size design of top device, a runner, waterways, mold size, analysis of the product 2D and 3D assembly drawing and parts drawing based on UG( Unigraphics) and CAD(Computer Aided Design).

Keywords: arc isolation board; UG; CAD;injection mould;plastic mould

目录

绪论 1

第一章塑件材料的工艺性分析 2

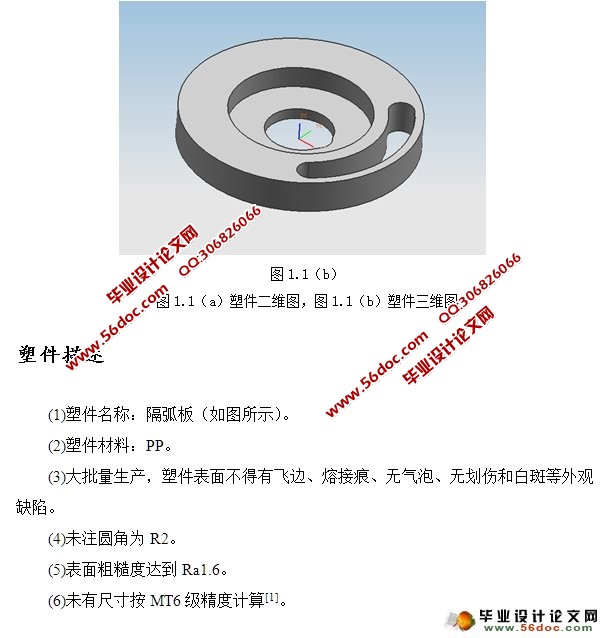

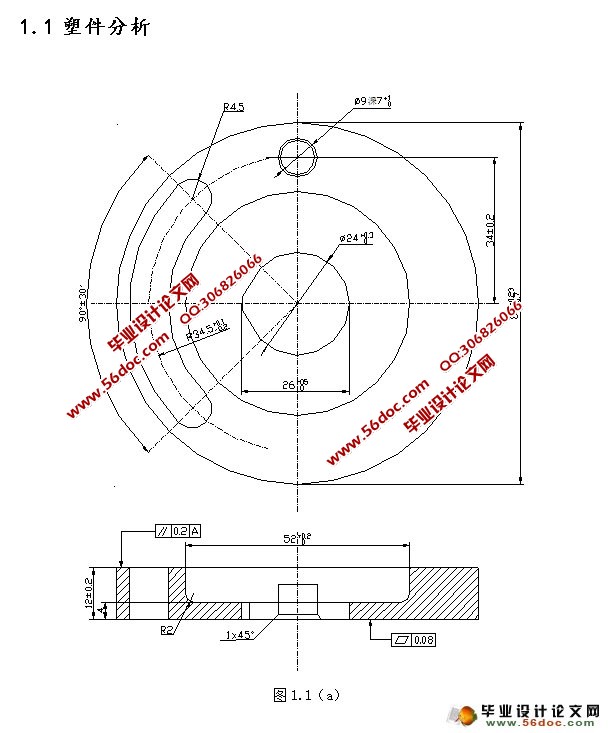

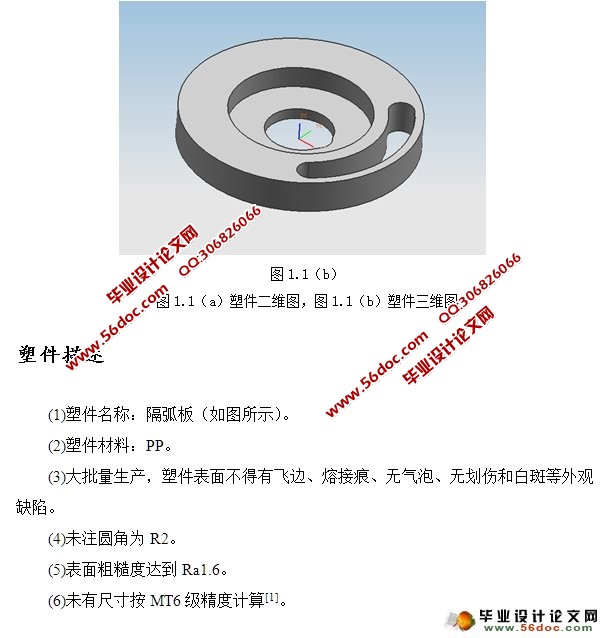

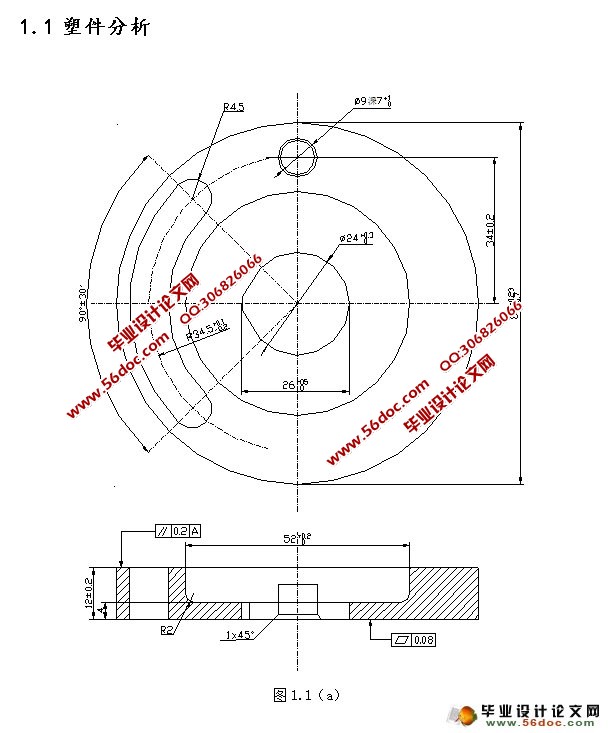

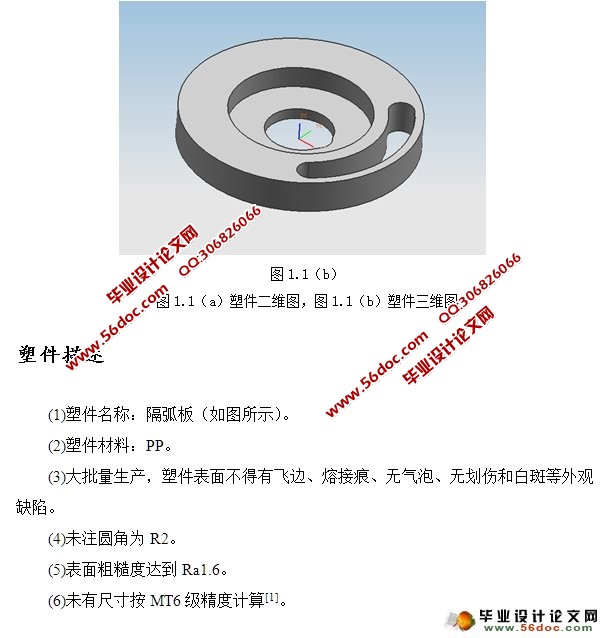

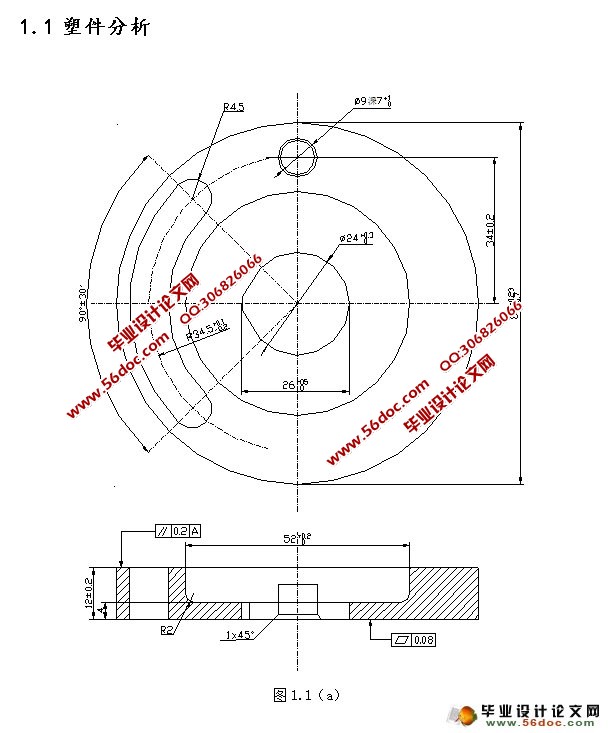

1.1 塑件分析 2

1.2 塑件描述 3

1.3 塑料性能分析 3

1.4塑料的特点分析 5

1.5 塑件的工艺分析 5

第二章注射机型号的选择 7

2.1 注射机的选定标准 7

2.1.1计算塑件的体积与质量 7

2.1.2确定模具型腔数量 7

2.2 注射机型号的选定 7

2.3 制定注射成形工艺参数 9

第三章模具结构设计 11

3.1 型腔数目的确定 11

3.1.1 确定型腔数目 11

3.1.2 型腔的分布 11

3.2 分型面的选择 12

3.3 确定模具总体结构类型 13

3.4 成形零件设计 13

3.4.1结构设计 13

3.4.2工作尺寸计算 13

3.4.3型腔侧壁和底板厚度计算 14

3.5 选择标准模架 15

3.5.1确定模架组合形式 15

3.5.2计算型腔模板周界 15

3.5.3选取标准的型腔模板周界尺寸 15

3.5.4确定模板厚度 15

3.5.5检验模架与注射机的关系 16

第四章浇注系统 17

4.1 主流道的设计 17

4.2 冷料穴设计 18

4.3 分流道的设计 18

4.4 浇口设计 19

4.4.1侧浇口的优点 20

4.4.2浇口位置的选择 21

第五章推出机构 22

5.1 推出机构的设计原则 22

5.2 推出机构的基本要求 22

5.3 推出机构的选用 23

5.3.1推杆的设计要求 24

5.3.2推杆的安装方法 24

第六章温度调节系统的设计 25

6.1 冷却系统 25

6.2 冷却介质 25

6.3 冷却系统设计原则 26

6.4 冷却装置的布置 26

第七章排气系统的设计 28

7.1 排气槽排气 28

7.2 分型面排气 28

7.3 利用型芯、顶杆、镶拼件等的间隙排气 28

第八章注射机的选材与校核 30

8.1 模具材料选用原则 29

8.2 本套塑料模具的选材 29

8.3注射机的校核 30

结论 32

参考文献 33

致谢 34

|