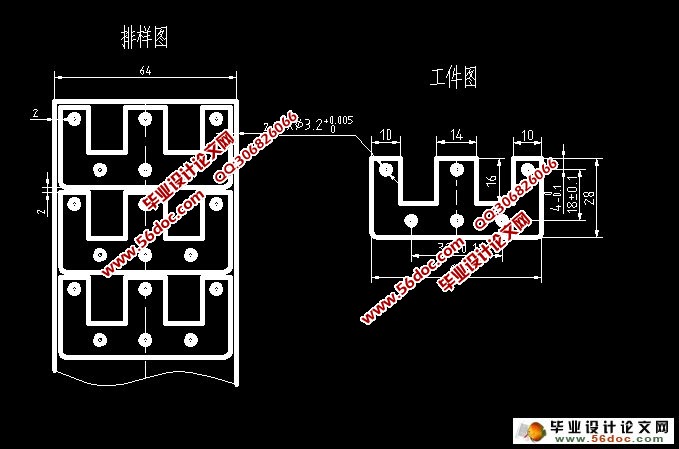

山字形铁芯片冲裁模设计(含CAD零件图装配图)(文献综述,设计说明书13000字,CAD图13张)

摘 要

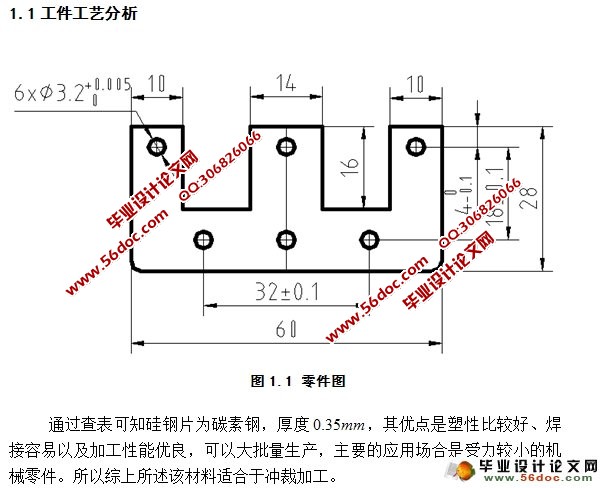

本次研究的课题是山字型铁芯片的冲压模具设计,通过对该制件的外形结构、尺寸大小和材料性质的分析,初步确认采用冲压的工艺方法。对工件进行工艺及其结构的分析,可以确定此零件适合冲裁制造,并从产品结构工艺性分析,通其结构的特点延伸,具体分析设计出符合预先设计的程度。首先通过分析可知该制件结构比较简单且高度对称,厚度较薄,要求大批量生产,属于一般的冲压制件,然后进行相关工艺的计算来确定模具的设计,另外在设计过程中成本因素也应该作为一个格外需要注意的因素考虑进去。

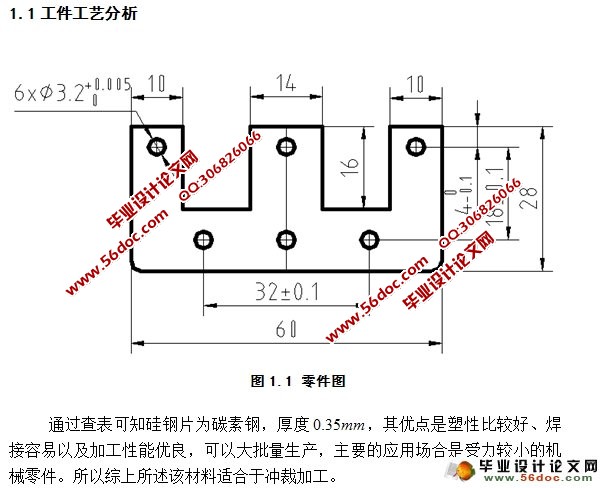

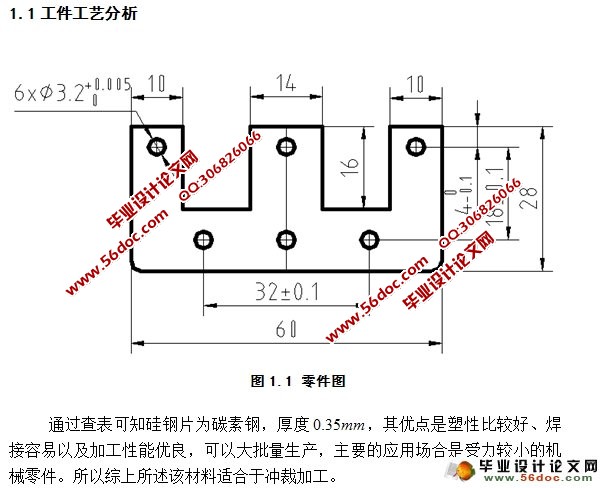

该制件厚度比较薄,只有 ,所以在产品生产完成之后的卸料装置上需要注意这个参数来设计相关机构。另外,由于制件所需要的冲孔直径很小,所以设计的冲孔凸模强度是否足够也是需要格外注意的。本制件所要求的精度也不是很高,制件未注尺寸精度为 级。

关键词:模具;冲裁件;冲孔;模具的装配;

Abstract

The study of the subject is e type iron chip of stamping die design, through to the appearance of the parts the analysis of the structure, size and material properties, preliminary confirm the stamping process. Analysis of workpiece process and its structure, suitable for cutting the parts manufacture can be determined, and from the product structural manufacturability analysis, through the mold structure characteristics, relevant parameters of molding part design, make its can meet the requirements of process parameters and production in advance. First of all, through the analysis on the structure is simpler and highly symmetrical parts, the thickness of the thinner, for mass production, belongs to the general stamping parts, and then the relevant process is calculated to determine the design of the mould, the other cost factors in the process of design should also be a need to be aware of all the factors into consideration.

The parts of thin thickness, only , so in the products production after completion of discharging device need to pay attention to this parameter to design the relevant institutions. In addition, because the punching parts need diameter is small, so the design of the punching punch strength is enough also need to be pay attention to. The parts required accuracy is not high, parts not note dimensional accuracy level .

Key words:The mould;Blanking pieces;punch;die intensive

目 录

绪论 1

1工件的工艺分析 4

1.1工件工艺分析 4

2工艺方案的确定 5

2.1方案的确定 5

2.1.1选定方案 5

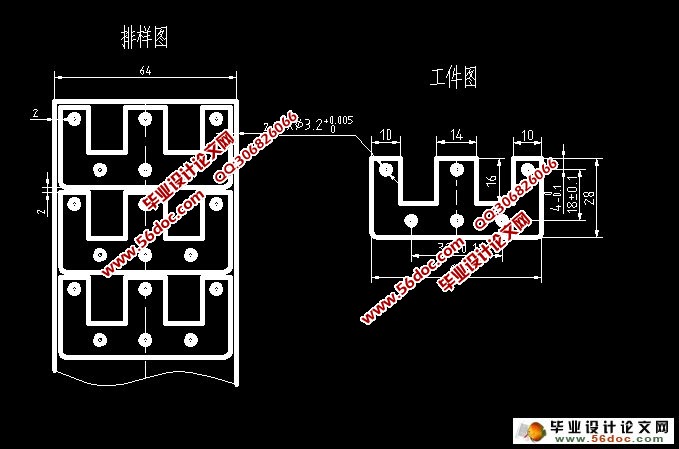

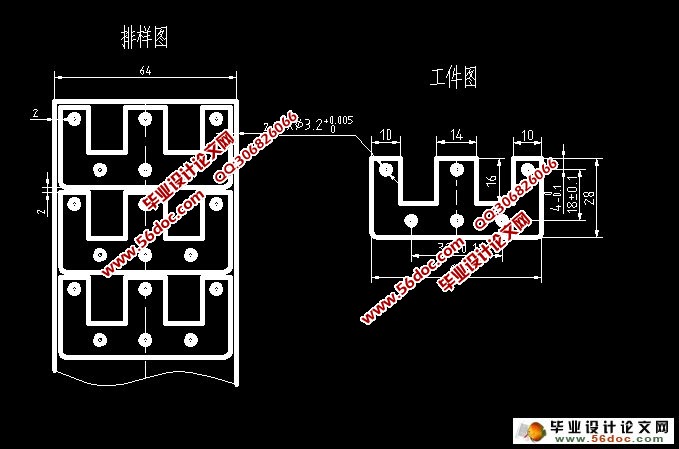

2.1.2冲裁排样设计 5

2.1.3搭边值的确定 6

2.1.4材料利用率的计算 7

2.2冲压力的计算 7

2.2.1冲孔力和落料力的计算 7

2.2.2卸料力和推件力的计算 8

2.3计算压力中心 8

2.4计算凹凸模刃口尺寸 8

2.4.1冲裁间隙的确定 9

2.4.2落料刃口尺寸的计算 10

2.4.3冲孔刃口尺寸的计算 10

3模具结构设计 12

3.1冲裁零件的设计 12

3.1.1落料凹模的设计 12

3.1.2冲孔凸模的设计 13

3.1.3冲孔落料凸凹模的设计 15

3.2定位零件的选择设计 16

3.3其他零件的设计 16

3.3.1卸料板的选择 16

3.3.2弹性元件的选择 17

3.3.3卸料螺钉的选择 18

3.3.4推件装置的设计选择 18

3.3.5模柄的选择 18

3.3.6凸模固定板和压板圈的设计 19

3.3.7螺钉和销钉的选择 20

3.4模架的选择 21

3.5压力机的选择 21

4模具的装配 23

结论 26

致谢 27

参考文献 28

|