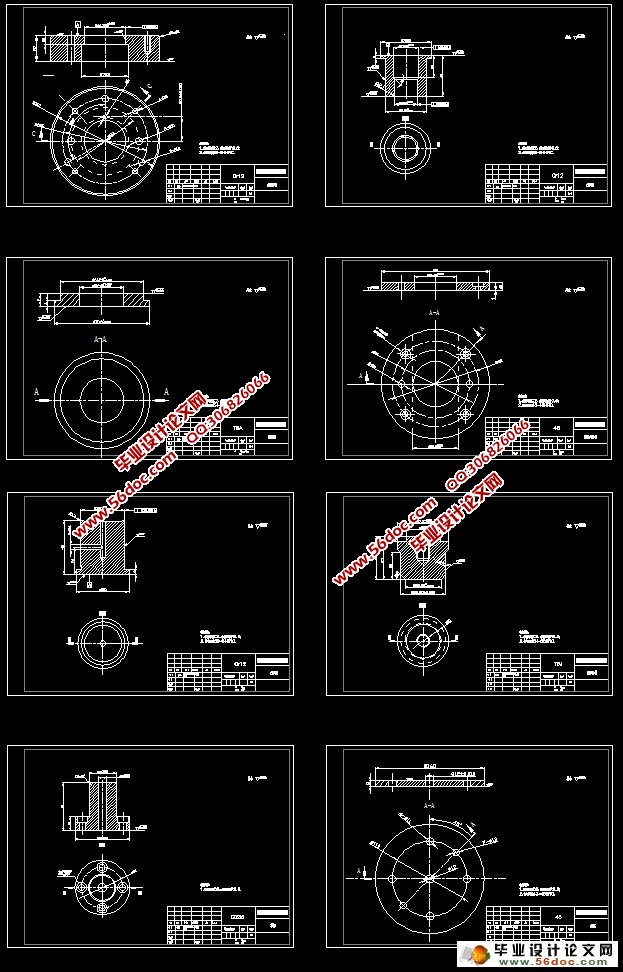

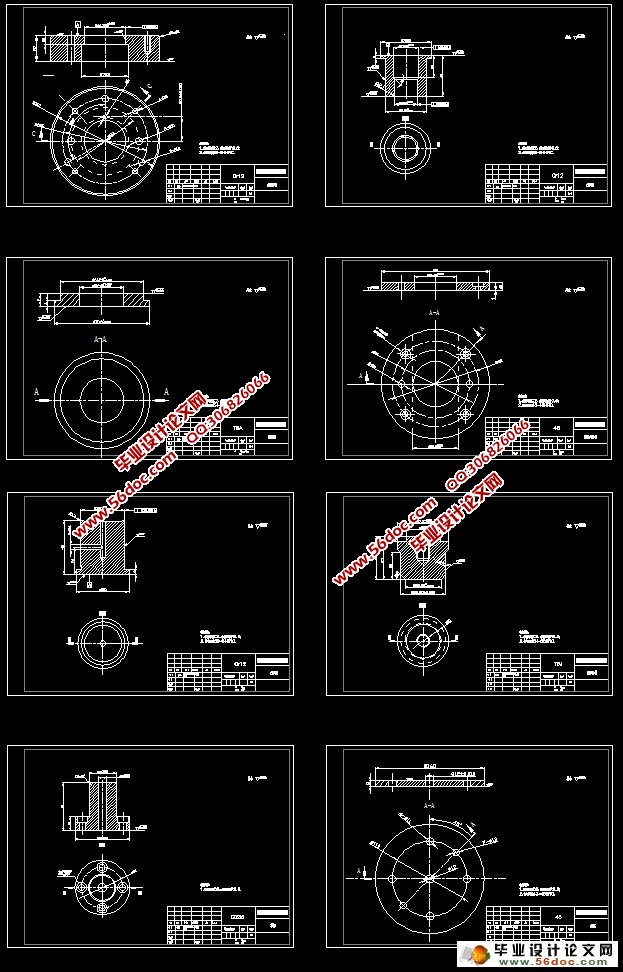

盖体模具设计(含CAD零件图装配图)(文献综述,论文说明书14500字,CAD图9张)

Cover body mold design

摘 要

本设计分析了盖体的结构和成形工艺,为了提高盖体模具的生产效率,该制件设计了落料、拉深、成形等工序,通过冲压工艺分析,结构设计,论证了其可能性和保证了制品的质量。

根据零件的设计尺寸要求、材料要求以及批量生产等要求,在分析好零件的工艺性之后,再制定工艺方案。再通过工艺计算来确定此模具的设计流程。模具加工工艺已经成为重要发展方向中的一项先进的制造工艺,如现在在汽车,航空等方面都是在广泛的应用。而会直接影响到生产产品的成本还有企业的经济利益更多的是因为模具的生产成本。

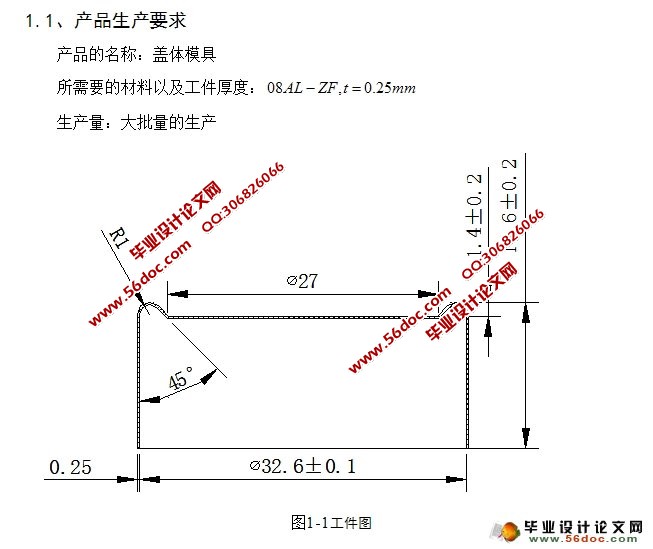

该模具设计的材料厚度比较薄只有0.25mm,拉深的高度也不是很高,可以一次拉深成功。精度也不算很高,一般都是在 级之间。在拉深成形没有达到我们所需要的工件时,可以再在后面加上整形这样一道工序来保证得到我们需要的模具。

在盖体模具设计中,为了提高成形速度和效率,充分利用我们所学的专业知识和资源。实践结果证明,有提高设计的速度和效率。此次模具设计中,由于卸料力较大,也采取了固定卸料板卸料力较大的优点来解决这一问题。

关键词: 落料 拉深 冲压工艺

Abstract

The design on the analysis of the structure of the cover body and the forming process,in order to increase the productivity of the cover body mould . This part designs the process of blanking ,drawing ,forming and so on , through process analysis, structure design, expounds the possibility and guarantee the quality of the products.

According to the parts of the design requirements,material requirements and mass production requirements ,in the analysis of the process of good parts ,and then develop the process plan ,and then through the process calculation to determine the design process of this mold .Mold processing technology has become an important development direction of an advanced manufacturing process ,such as the present in the automotive ,aviation and other aspects are in a wide range of applications.And will directly affect the cost of the production of products and the economic benefits of enterprises is more because of the mold production costs.

The mold design of the material thickness is relatively thin only 0.25mm ,the height of the drawing is not very high ,you can draw a successful .Accuracy is not very high ,generally is between level .In the deep drawing process is not necessary to achieve the work piece we need ,can be added in the back and shaping such a process to ensure that we need to die.

In the cover body mold design, in order to improve the forming speed and efficiency, make full use of what we learn professional knowledge and resources. Practice proved that can improve the speed and efficiency of design. In the design of the mold, due to large discharge force, also adopted a fixed stripper plate is a little bit to the larger discharge force to solve this problem.

Key words: blanking; Deep drawing; Stamping process

目 录

绪 论 1

1、工艺分析及工艺方案确定 3

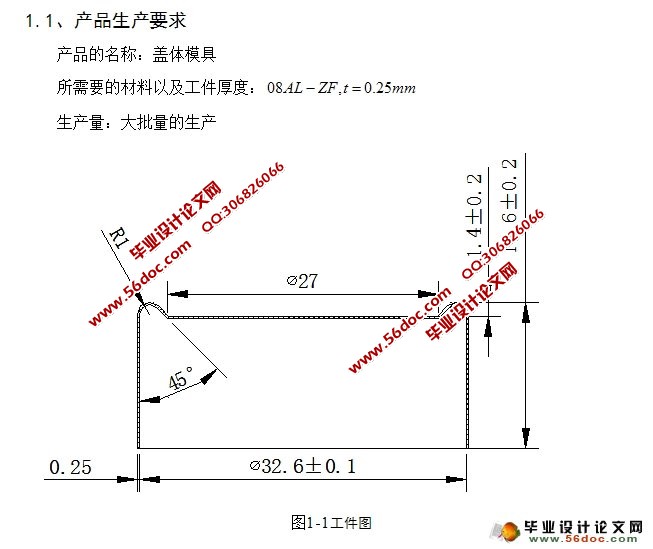

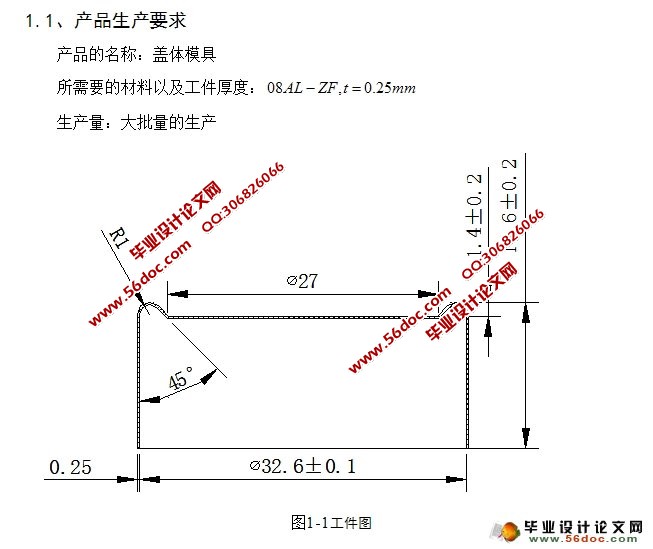

1.1、产品生产要求 3

1.2、工艺分析 3

1.2.1结构的工艺性分析 3

1.2.2形状的工艺性分析 4

1.2.3尺寸精度的工艺分析 4

1.2.4考虑经济成本并分析 4

1.2.5材料的性质 4

1.3、工艺方案的确定与分析 5

2、工艺计算 6

2.1毛坯尺寸的确定以及材料排样 6

2.1.1 修边余量的选取 6

2.1.2 计算毛坯尺寸 6

2.1.3 拉深的形式以及拉深的次数 6

2.1.4材料排样及材料的利用率的计算 7

2.2、冲压力的计算 9

2.2.1 计算出拉深凹、凸模的圆角半径 9

2.1.2落料力 10

2.2.2卸料力和推件力以及顶件力 10

2.2.3拉深力 11

2.2.4压边力 11

2.2.5成形力 11

2.2.6切边力 12

2.3冲压设备的初步选择 12

2.4、确定冲裁间隙和计算主要工作部分的尺寸 13

2.4.1冲裁间隙的影响 13

2.4.2计算出落料凸凹模的尺寸 14

2.4.3计算出拉深凸凹模的尺寸 14

2.4.4计算出成形凸、凹模的尺寸 15

3、结构设计 16

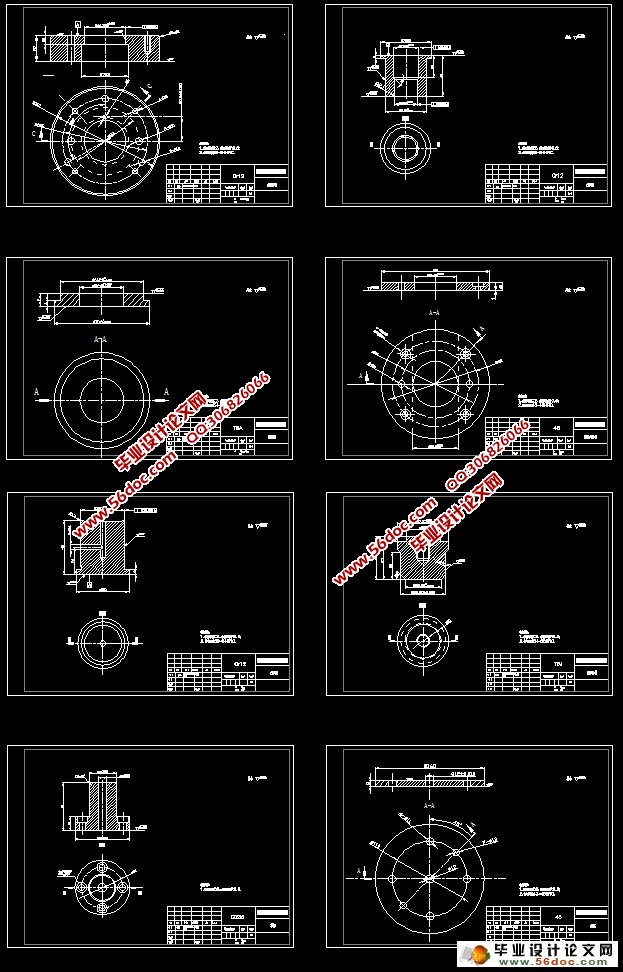

3.1冲压的零件结构设计 16

3.1.1确定凹模结构尺寸 16

3.1.2凸凹模的长度计算 17

3.1.3设计拉深凸模的结构 18

3.1.4设计成形凸模 18

3.1.5设计刚性卸料板的结构 19

3.1.6垫板的选取 20

3.1.7压边圈 21

3.2标准件的选用 22

3.2.1模架的标准选用 22

3.2.2选取标准螺钉 22

3.2.3圆柱销的采用 23

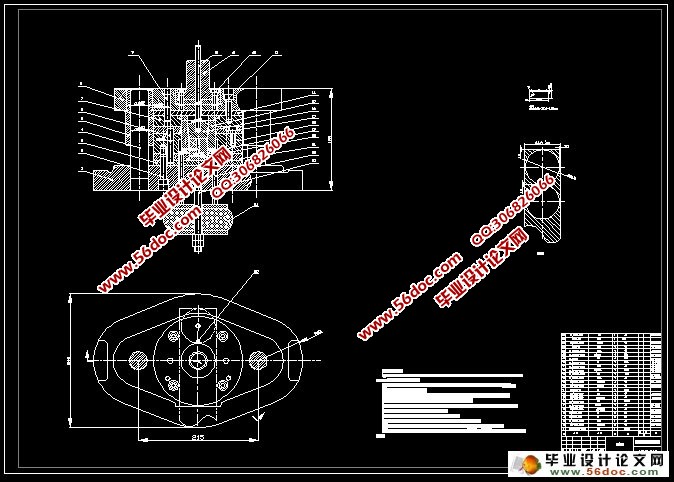

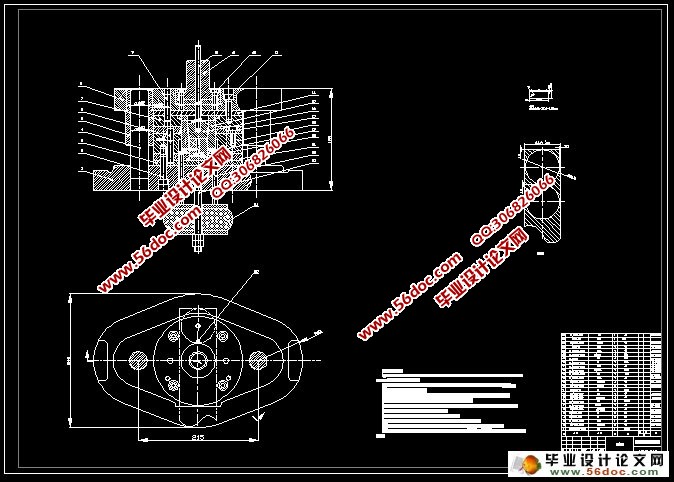

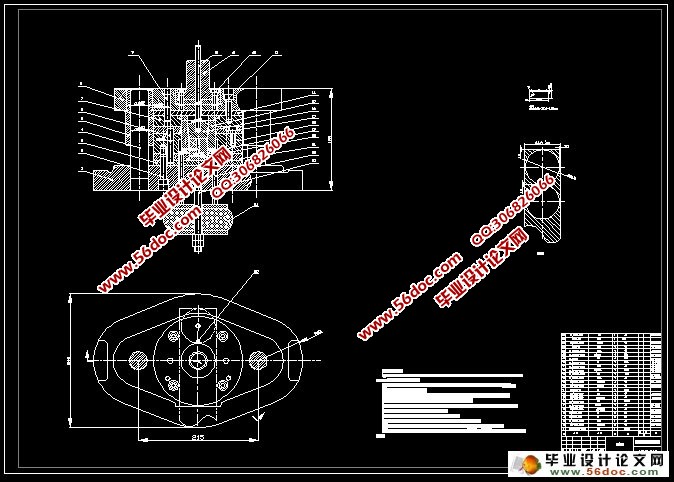

4. 装配图 24

4.1工作过程 24

4.2模具总装 25

结 论 26

致 谢 27

参考文献 28

附录 29

|