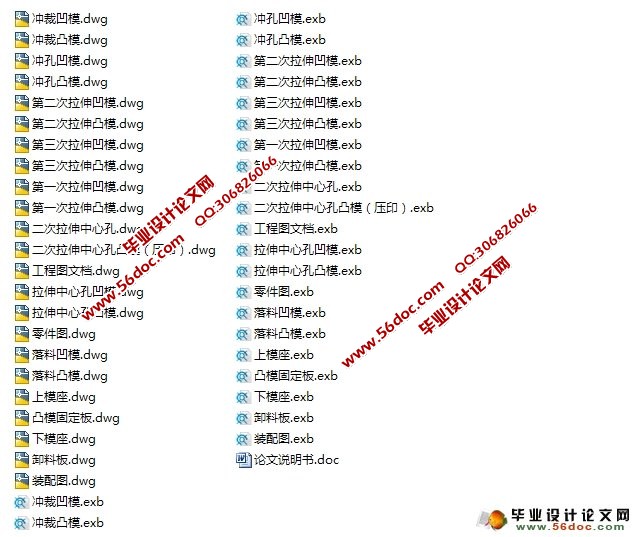

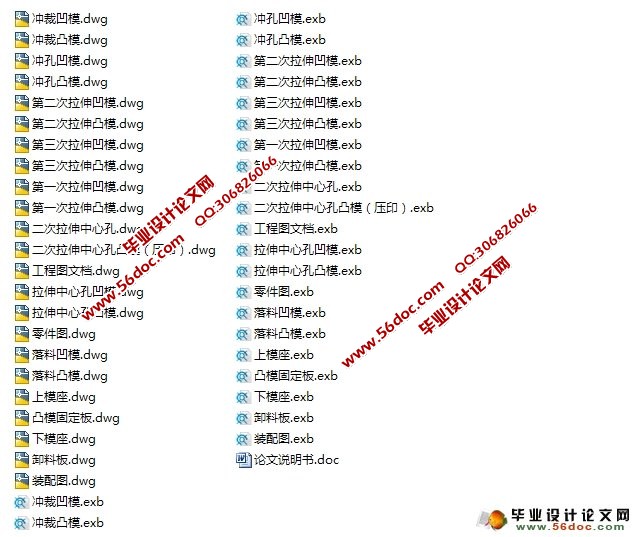

端盖级进模的设计及其制造工艺(冲压模具)(含CAD图纸,CAXA图)(论文说明书15000字,CAD图纸23张,CAXA图纸23张)

摘 要

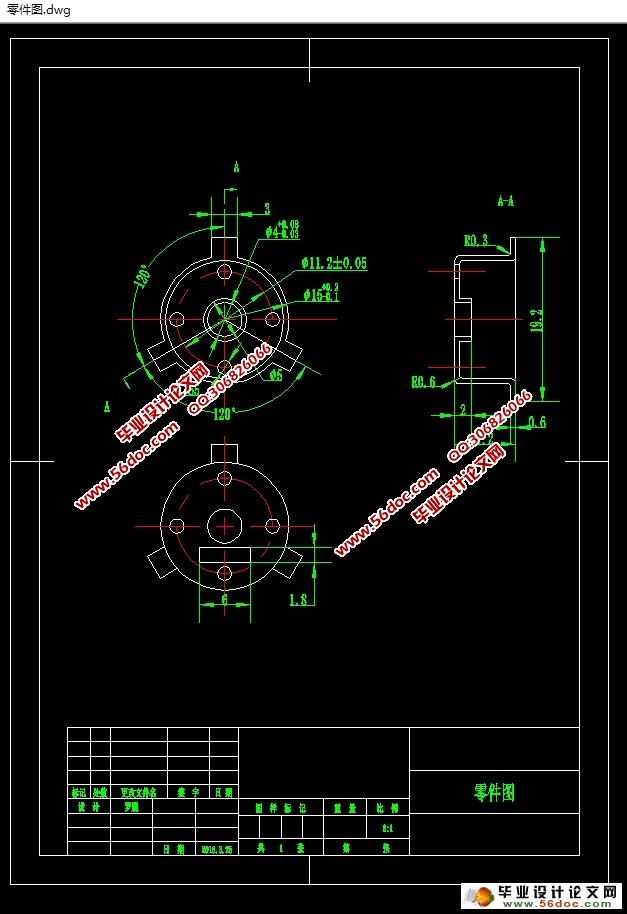

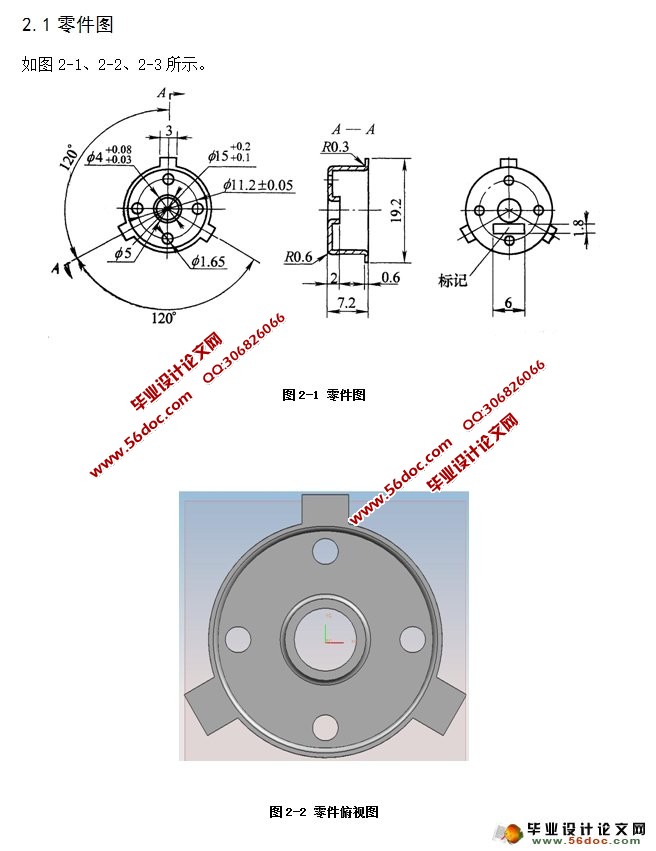

本文主要研究端盖级进模的设计及其制造工艺。本论文应用专业所学课程的理论和生产实际知识,进行一次冷冲压模具设计工作的实际训练从而培养和提高学生独立工作能力,巩固与扩充了冷冲压模具设计等课程所学的内容,掌握冷冲压模具设计的方法和步骤,掌握冷冲压模具设计的基本技能,懂得怎样分析零件的工艺性,怎样确定工艺方案,通过对比和结合实际生产需要,明白了单工序模、复合模、级进模各个优势所在,了解了模具的基本结构,提高了计算能力,绘图能力,熟悉了规范和标准,同时各科相关的课程都有了全面的复习,独立思考的能力也有了提高。结构采用级进模,能更简单的实施自动化操作。另外,级进模凹模采用镶件,能使在实际生产中更易换模、维修、保养,从而使得提升工作效率。主要工序包括:a拉深,b冲孔,c翻边,d压印,e落料。本设计分别论述了产品工艺分析,冲压方案的确定,工艺计算,模板及零件设计等问题。

关键词:冲裁工艺;级进模;计算机辅助设计

Abstract:

This text main research design and manufacture process of the progressive die for the cover. This thesis applied professional curriculum theory and the actual production of knowledge, to cultivating and improving students' ability to work independently with doing a cold stamping mould design in practical training work, consolidated and expanded the course content of cold stamping mould design, grasps the methods and steps of cold stamping mould design, Master design basic skills of cold stamping mould, know how to analysis the parts manufaturability, determine the process. Through the comparison and combined with the actual production needs, understand the advantage of procedure, composite modulus, progressive die, understand the basic structure of mould, improve the ability of calculating and drawing, familiar with the specifications and standards, comprehensive review each subjects those related knowledge in the same time, and improving my independent thinking ability. Structure determine use progressive die which can make automation simple. And female die use insert, make mould changing, maintenance and maintain easier, then improve the work efficiency during the actual production. The main processes including that drawing,punching,flanging,pressure seal and blanking. The product process analysis, determine the stamping scheme, process calculation, templates design, parts design are discussed respectively in design.

Keywords : Blanking craft;Progressive die;CAD

目录

1 绪论 1

1.1冲压模的简介 1

1.2级进模国内外研究现状与发展趋势 2

2 总体计算 4

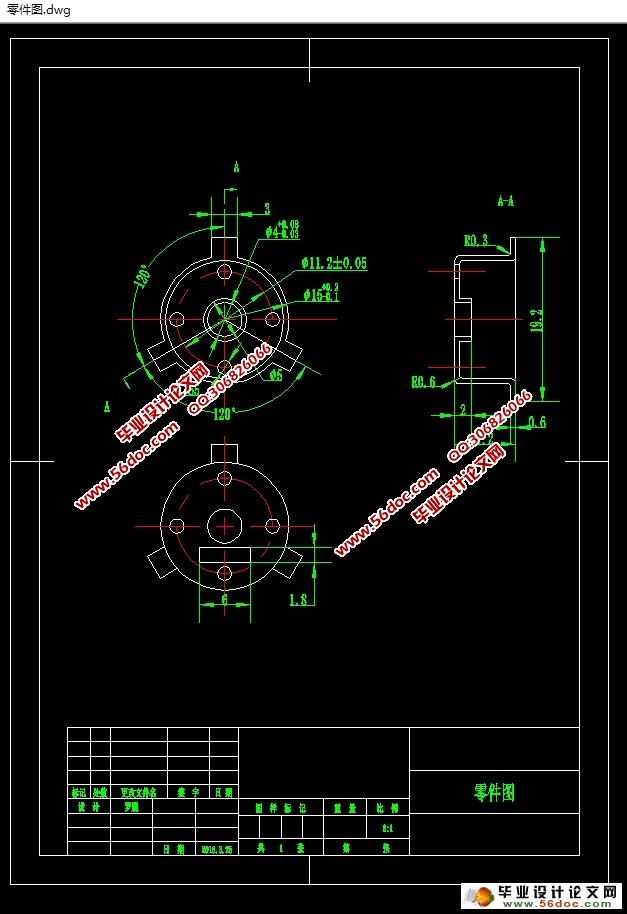

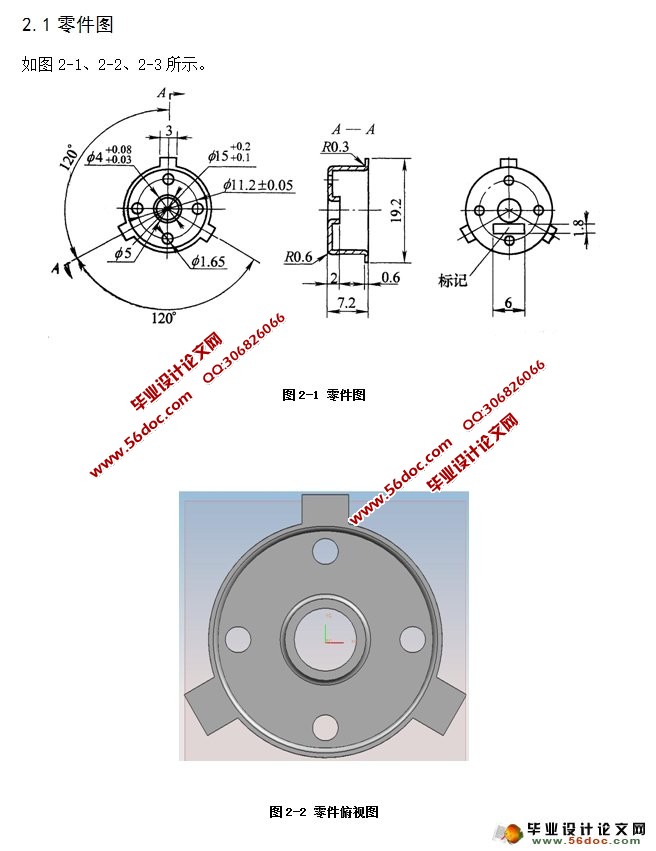

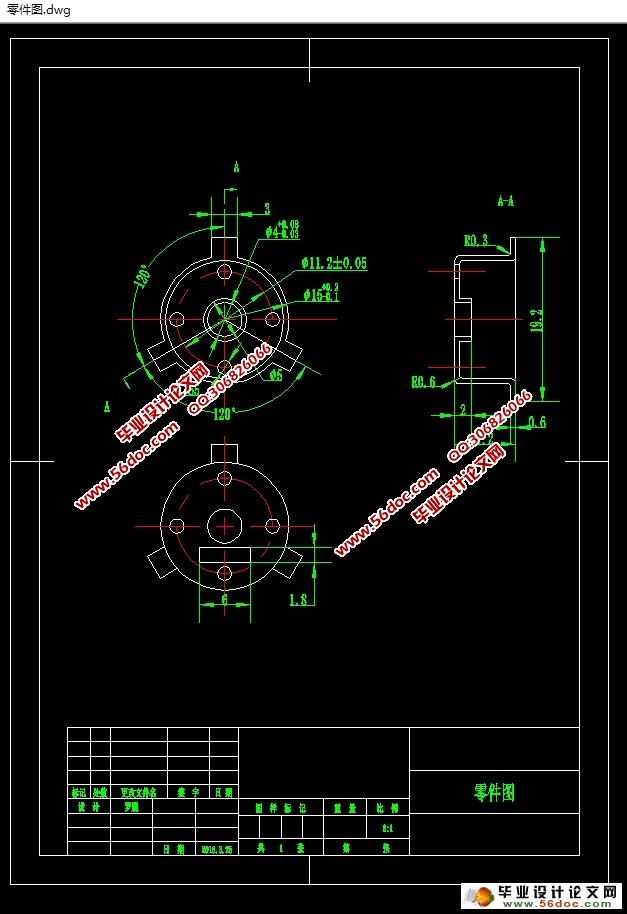

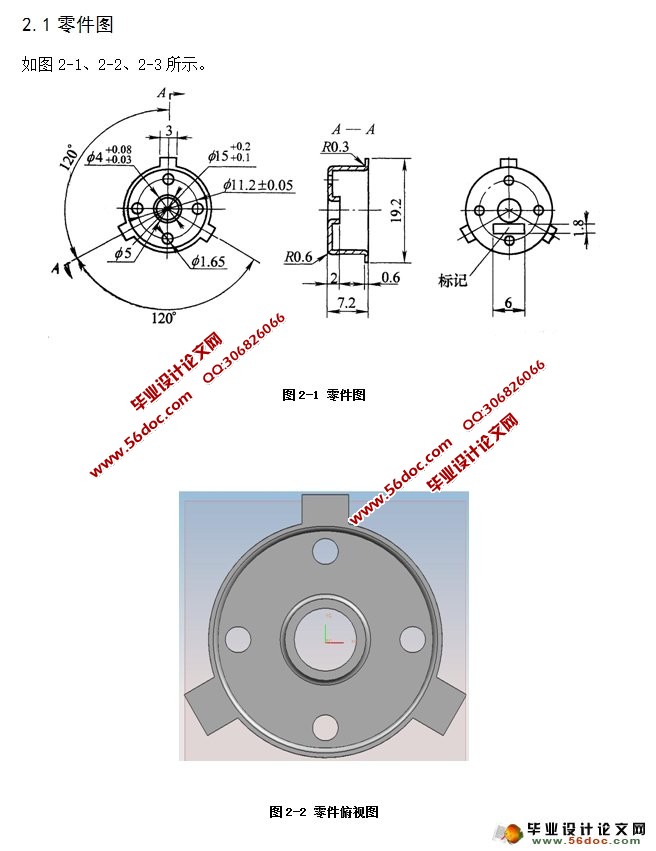

2.1零件图 4

2.2研究方案确定 6

2.3 排样图的设计与计算 9

2.4 材料利用率、冲裁力及压力机的选择 12

2.5模具刃口尺寸计算 17

3 结构设计 24

3.1设计原则 24

3.2凸凹模原则 24

3.3模架及其他零件设计、选用 25

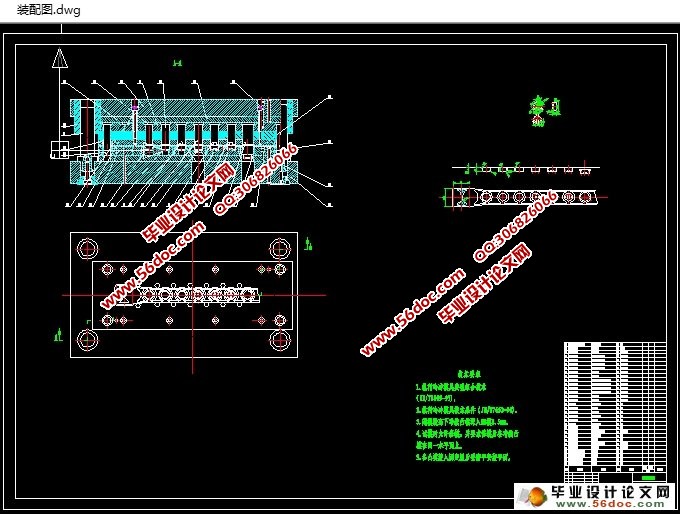

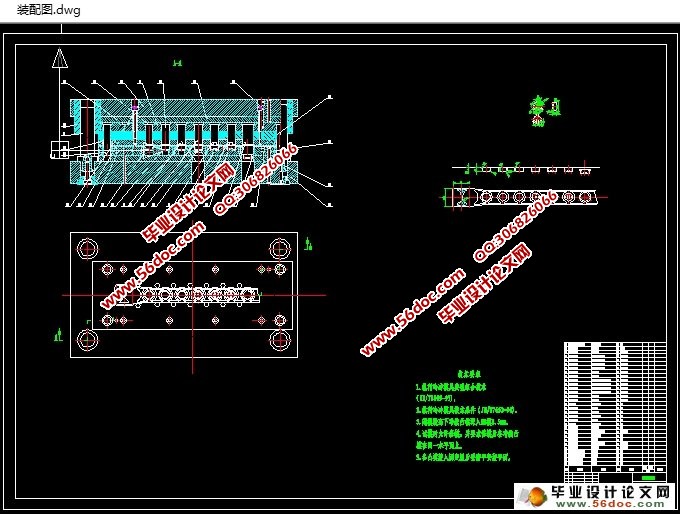

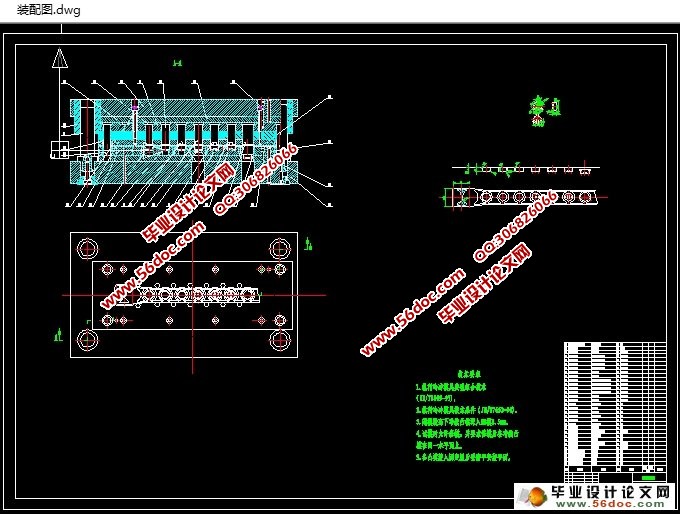

4 模具装配工艺 28

4.1冲裁模装配的技术要求 28

4.2 模具总装 28

4.3 凸、凹模间隙的调整 29

5 零件的工艺方案 30

6 典型零件制造工艺 31

6.1凹模板的加工工艺 31

6.2圆形凸模加工工艺 31

7 结论 32

参 考 文 献 33

致 谢 34

|