电视机旋钮注塑模具设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书6600字,CAD图纸18张)

摘 要

目前,许多工业发达的国家模具工业的产值都已经超过了机床工业的总产值。美国模具工业的每年产值已经有100亿美元,日本1957年到1984年27年间,模具工业迅速增长,接近一百倍,1987年台湾地区模具出口量达到一亿二千万美元,香港的模具工业的每年产值约为三十亿港币,然而我国模具年产值却只有30亿人民币。从这些模具年产值信息可以看出我国模具在数量质量技术上都有了长足进步,也足可看出我国旋钮工业的进步,单和世界先进水品相比还差了很多。主要缺陷有,模具精度低,技术含量不高,复杂程度不高。因此我多每年都要大量进口外国高档塑料模具。中国塑料模具行业尽管发展迅速但是仍然存才很多缺陷,主要有:组织协调能力差;工艺装备落后;开发能力弱,创新能力不足;人才不足;产品技术不高。这些严重阻碍着我国模具工业的发展。我国现在最大的不足在于空有好的模具设计图却没有办法将模具完整做出来。所以我们必须吸收国外的先进技术,加以学习,实践,改良。

我们不能局限于国内市场,还要放眼世界市场,因为未来模具的发展必定会越来越先进,竞争越来越激烈。

关键词:模具工业;缺陷;塑料模具;

Design of injection mould for TV set knob

ABSTRACT

At present, many developed countries die industry output value has exceeded the total industrial output value. The annual output value of machine tool mould industry has reached 10 billion U.S. dollars, Japan from 1957 to 1984 in 27 years, the rapid growth of mold industry, nearly one hundred times, reaching $one hundred and twenty million in 1987 in Taiwan mold exports, the annual output value of about three billion yuan in Hongkong Hongkong mold industry, however, the mold of the annual output value of only 3 billion yuan. But from the mold annual output value of the information can be seen, much progress has been made in a number of China die technology, but also can see, Chinese single knob industrial progress, compared with the world advanced water products, is worse. The main defects of the mold, the precision is low, the technical content is not high, the complexity is not high. So I have every year a large number of imported high-grade plastic mold, plastic mold industry in China and Chinese. Advanced aquatic products are The following problems, backward technology and equipment, organization and coordination ability difference; development capacity is weak, lack of innovation; lack of talent; development is not balanced, low overall quality products. These are serious obstacles to the development of industry of our country mould. Mould design in the industry of our country mould is the biggest problem. Therefore, it is necessary to draw lessons from foreign advanced technology, improve the scientific and technological content.

In the future, the development direction of the injection mold must be large, high precision, and the development direction of the energy saving compound die.

Key words: mold industry; defect; plastic mould;

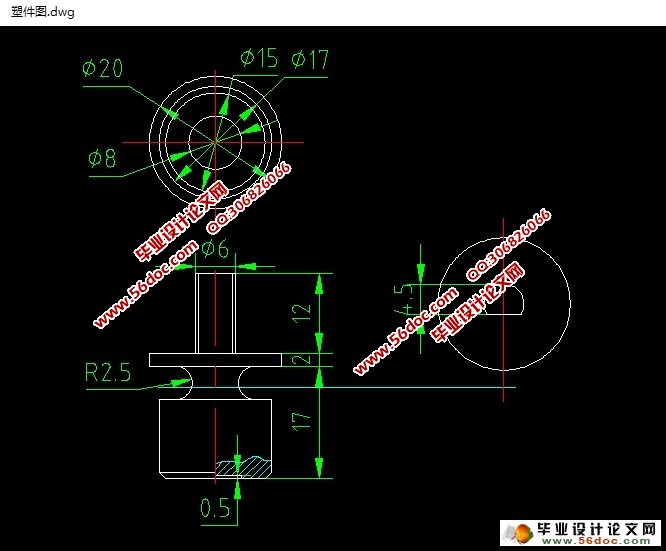

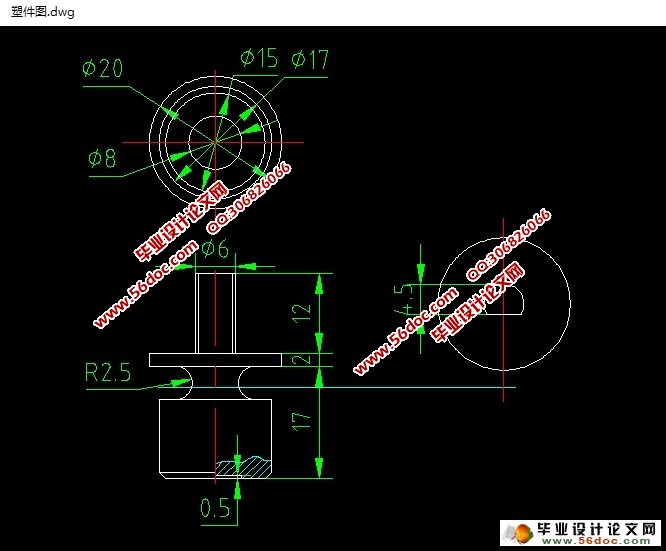

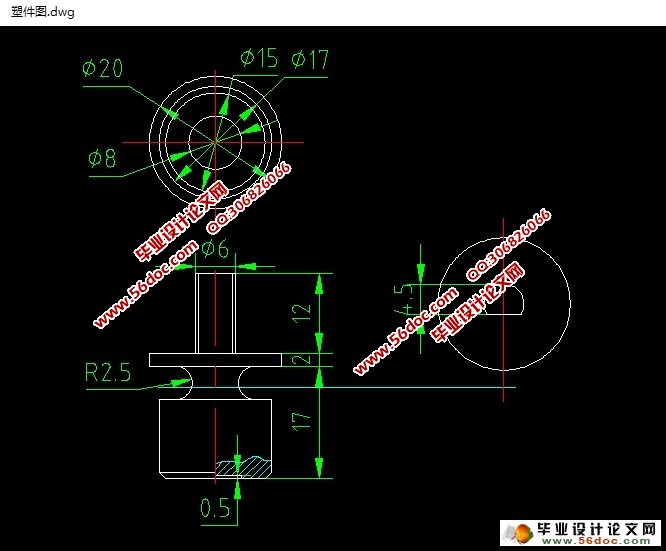

塑件结构工艺性分析

1).塑料零件的圆柱旋转件,高度为31毫米,每节的厚度是不同的,整体的大小是20毫米。

2).成形塑件长度为12mm的杆状部分采用镶件结构,塑料件的圆周内凹槽形成后表面平整;它必须使用侧滑块侧向分型机构,利用斜导板起开合模的导向作用,用成型推杆成型来成型塑件表面 的圆形凹槽。

目 录

摘 要....................................................Ⅱ

ABSTRACT.................................................Ⅲ

1.绪 论 .......................................... 1

2.塑料制品的工艺性分析................................... 2

1. 塑件的分析......................................... 2

2.塑件尺寸精度分析.................................... 2

3 .塑件表面质量分析.................................... 3

4 .塑件结构工艺性分析.................................. 3

3.成型设备的选择和模塑工艺规程编制....................... 4

1.计算塑件体积、重量.................................. 4

2.注射机XS-ZY-60的主要技术参数:..................... 4

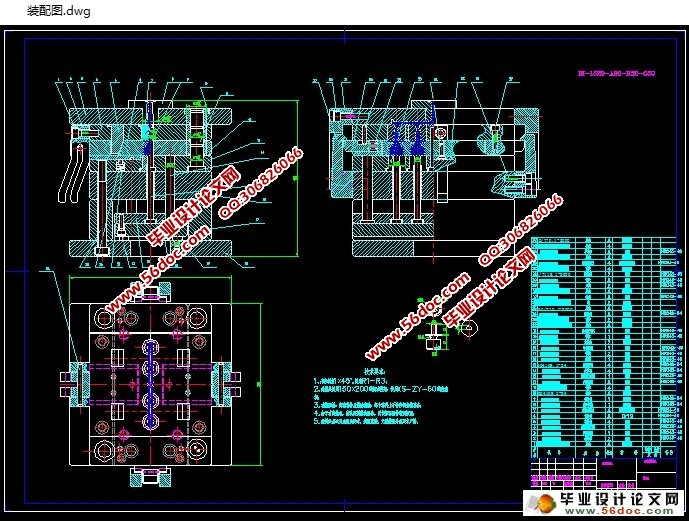

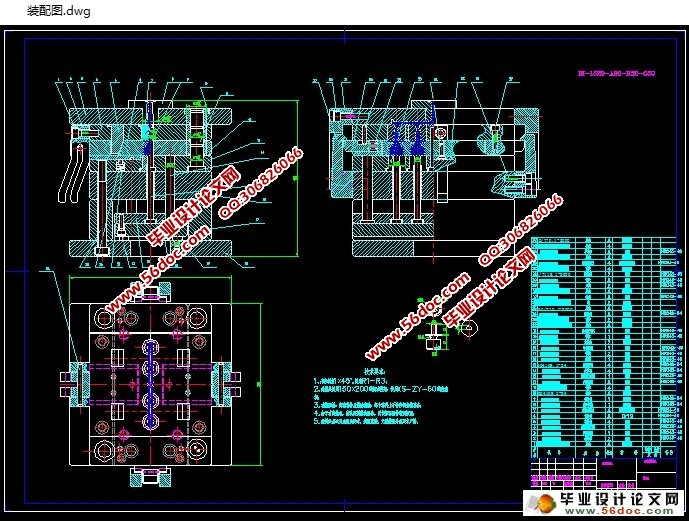

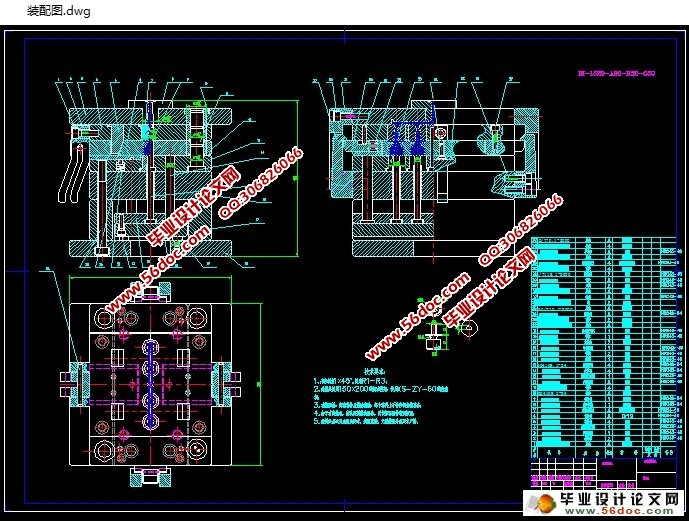

4. 注射模结构设计........................................ 5

1.分型面的选择........................................ 5

2.浇注系统............................................ 5

3.型腔设计... ........................................ 6

4.侧向分型 ........................................... 8

5.推件方式............................................ 8

6.冷却与加热系统...................................... 8

7.标准模架的选用...................................... 8

5.成型零件尺寸计算....................................... 9

6.注射机有关参数的校核.................................. 10

7.模具装配图 ............................................13

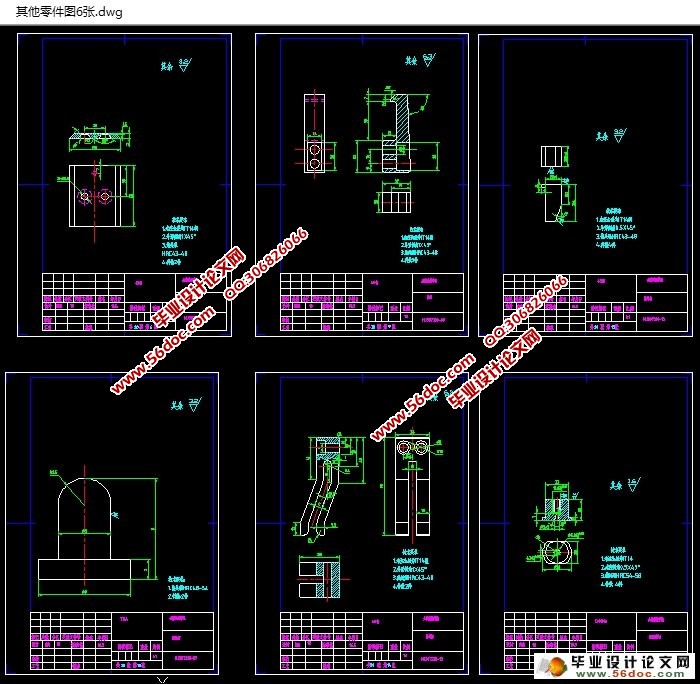

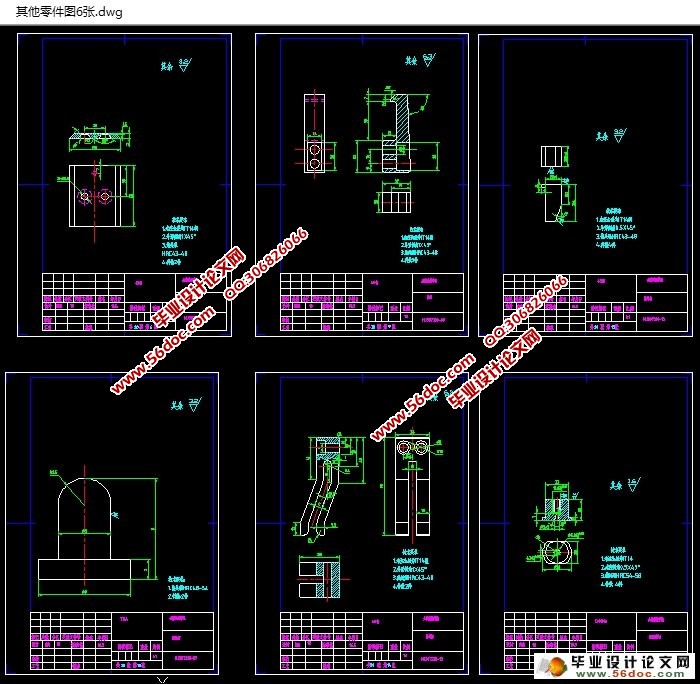

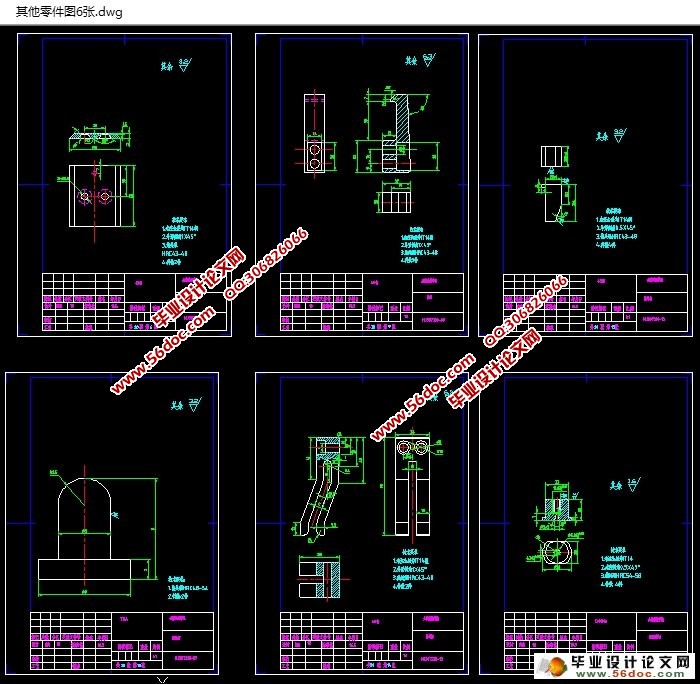

8.主要模具零件加工工艺...................................14

结论.....................................................16

参考文献.................................................17

致 谢...................................................18

|