透明盒盖注射模设计(含CAD零件图装配图)(开题报告,文献综述,设计说明书11000字,CAD图6张)

The design of the injection mold for the transparent cover

摘 要

最近这些年来,中国快速发展的经济对模具行业提出了更高的要求,特别是塑料模具行业。截至2004年,塑料模具在整个模具行业中的比重,已上升到百分之三十左右,推测在未来几年中,塑料模具行业将保持较高的百分之十以上的年均增长速度。在国内模具市场上以塑料模具需求量最大,塑料模具又以注塑模具需求量最大,我们的重点是发展塑料模具。

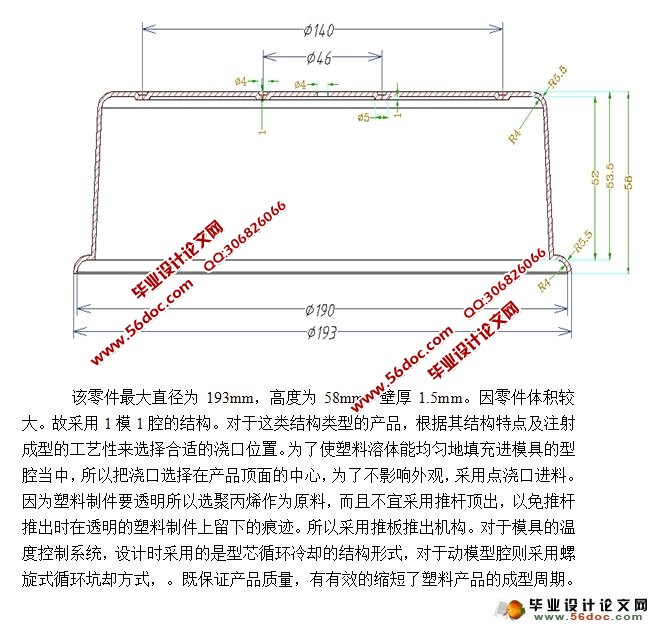

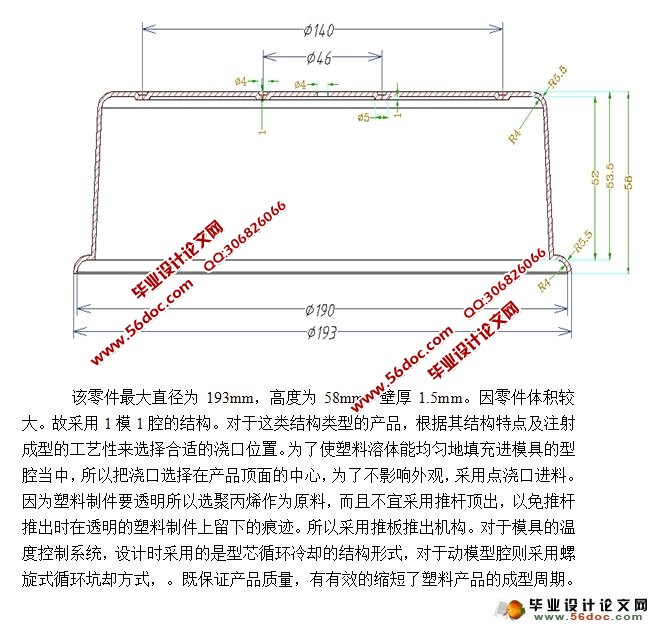

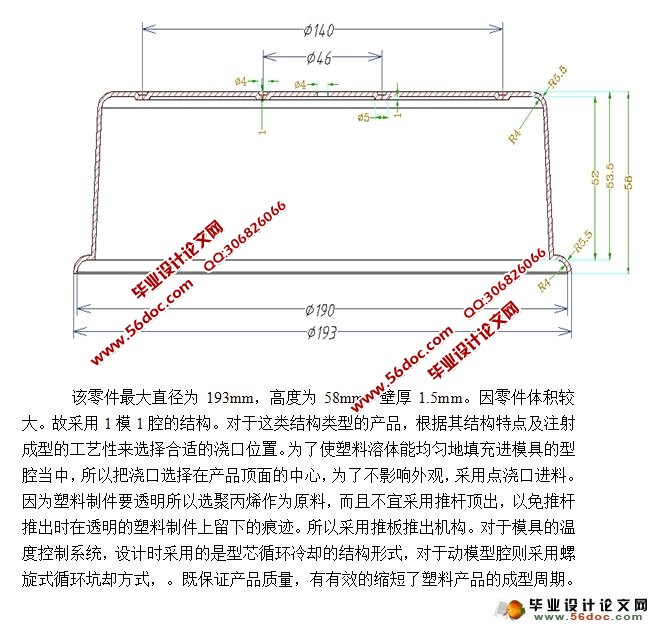

注射成型是塑料成型,也被称为注塑模。是塑料成型常用的的重要方法之一,塑料注塑成型是在金属压铸成型的基础上发展而来的,成型用的是注塑机。它一般适用于热塑性塑料成型。热固性塑料注塑成型的应用正在研究和推广中。模具生产自动化程度最高的是塑料成型,塑料成型同时也是现在最广泛使用的一种成型方法。这次的课题是以透明盖作为设计模型,使用注射模具知识作为基础来说明注塑模具设计过程。

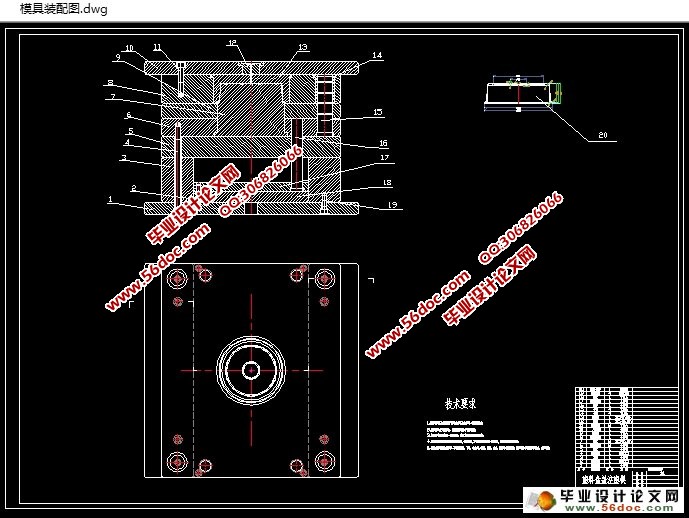

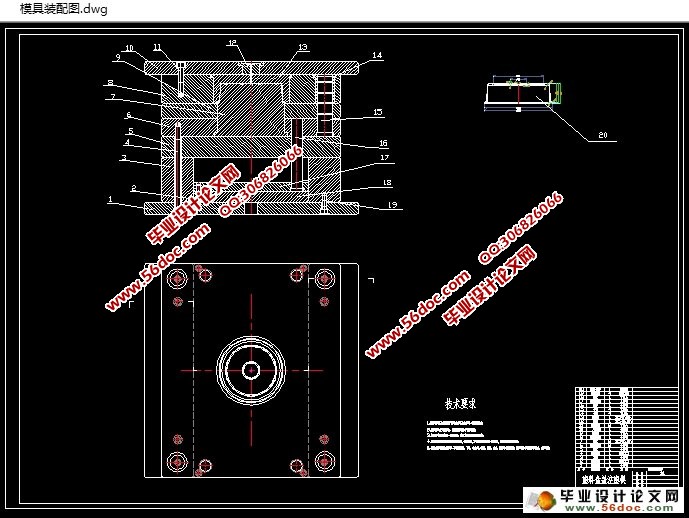

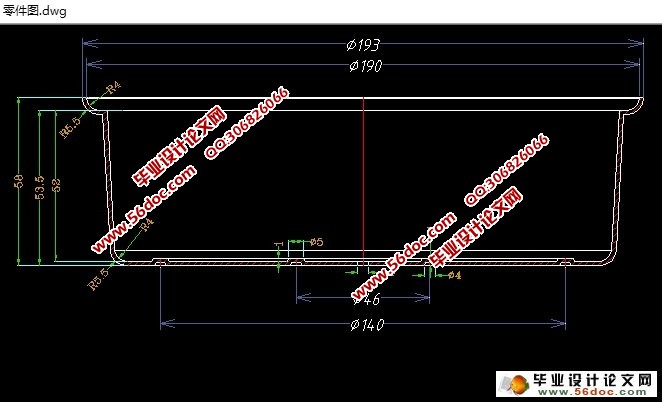

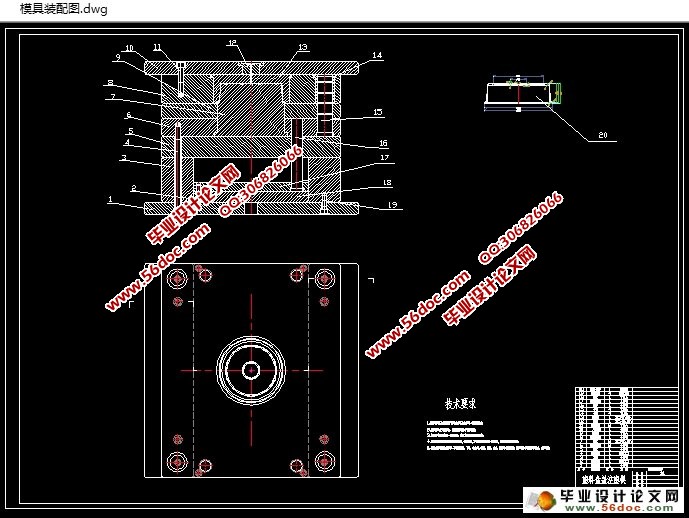

注塑模具的透明盒盖的设计采用的ProE软件实体造型的进行实体造型,对塑料件的结构进行分析处理。从而确定的设计构造,确定注塑过程,仔细的计算并且验证的各个部分。这样的设计,以确保模具工作的正常,确保他们与其他的结构的配合。最后,运用CAD二维制图绘制模具零件图和装配图。

本课题通过透明盖注塑模具设计,巩固了所学的知识,取得了满意的效果,达到设计意图的想法

关键词:塑料模具;注射成型;模具设计;

ABSTRACT

In recent years, the rapid development of Chinese economy, the mold industry has put forward higher requirements, especially plastic mold. By 2004, the proportion in the mold industry, plastic mold has risen to about 30%, suggesting that in the coming years, the plastic mold industry will maintain an average annual growth rate of more than 10% higher speed. In the domestic market, plastic mold injection mold to the greatest demand, which focuses on the development of plastic mold.

Injection molded plastic molding, injection molding is also known. Is one of the important methods of plastic molding, plastic injection molding development is based on the development of metal casting, molding is injection molding machine. It generally applies to thermoplastic molding. Thermosetting plastic injection molding applications is being expanded. Most automated production is a method of molding a plastic molding, plastic molding is the most widely used. The subject is the transparent cover as a design model, using an injection mold knowledge as a basis to illustrate the injection mold design process.

Transparent lid injection mold design using ProE solid modeling software was solid modeling, structural analysis and processing of plastic parts. To determine the design structure, determine the injection molding process, careful calculation and verification of the various parts. This design, in order to ensure the normal work of the mold, to ensure that they cooperate with other structures. Finally, the use of CAD drawing draw mold parts and assembly drawings.

This topic through the transparent cover injection mold design, consolidate what they have learned, and achieved satisfactory results, to meet the design intent ideas

Keywords: plastic mold; injection molding; mold design;

目 录

绪论 6

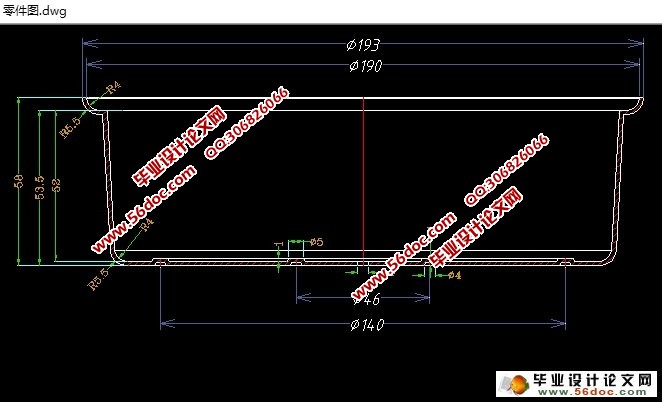

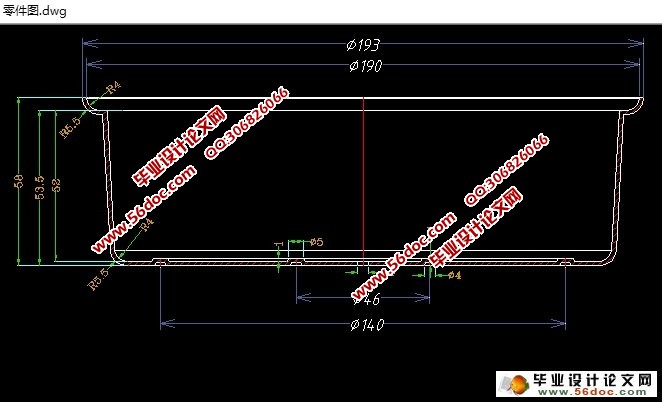

1零件工艺性分析 7

1.1制件的几何形状分析 7

2.2型腔数量的确定 7

1.3制件原材料的成型特性 8

1.4注塑设备的选择 9

1.5锁模力的校核 11

1.6模具开模行程的校核 11

2分型面位置的确定 12

2.1分型面的选择 12

3浇注系统的设计 14

3.1 主流道的设计 14

3.2 浇口设计 15

3.3浇口位置的选择: 16

4成型零件的设计 17

4.1结构设计 17

4.2工作尺寸计算 17

4.3成型零件的强度和底板厚度计算 19

4.4成型零件钢材 20

4.5标准模架的确定 21

4.6 模架各尺寸的校核 23

5成型设施备的校核计算 24

5.1注射机注射压力校核 24

5.2注射量的校核 24

5.3锁模力的校核 24

5.4推出机构的校核 25

6 导向机构的设计 26

6.1导向装置的作用: 26

7 温度调节系统 28

8 排气槽的设计 30

9模具的总体结构 31

9.1模具的工作过程 31

总结 33

参考文献 34

致谢 35

|