摘 要

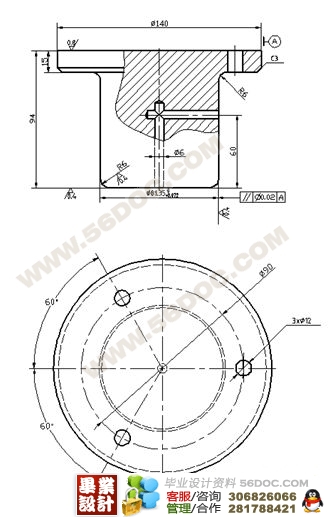

随着中国工业不断地发展,模具行业也显得越来越重要。本论文便是设计加工空气滤清器壳的模具。首先对加工零件进行了加工工艺和结构工艺的分析。通过计算毛坯尺寸和拉深系数提出了四种方案,最后确定采用落料、正反拉深复合模。对模具的排样做出了合理的布置,使材料利用率达到较高的水平。计算了冲压过程中所需要的各种冲压工艺力,包括落料力、卸料力、压边力、拉深力、顶料力等,并对压力机进行了合理的吨位初选。复合模在结构上采用了正装的形式,计算出了落料、正拉深和反拉深工作部分的尺寸。对模具的闭合高度进行了合理的确定,还设计出模具的主要零件落料凹模、凸凹模、反拉深凸模、反拉深凹模、凹模固定板等。列出了模具所需零件的详细清单,并给出了合理的装配图。由于拉深的深度较大,对压力机的电机也进行了功率校核并提出了润滑的附加工序,能使拉深顺利完成。最后对模具的一个主要零件导套进行了简单的加工工艺路线的制定。本设计对于采用单动压力机进行正反拉深具有一定的参考作用。(所有权: 毕业设计网 )

关键词 毕业论文;模具设计;复合模;正反拉深

ABSTRACT

Develops unceasingly along with the Chinese industry, the mold profession also appears more and more importantly. The present paper then is designs the processing air filter shell the mold. First has carried on the processing craft and the structure craft analysis to the processing components. Proposed through the computation semifinished materials size and the drawing coefficient four kind of plans, finally determined uses falls the material, the pro and con drawing superposable die. Has made the reasonable arrangement to the mold platoon type, enables the material use factor to achieve the high level. Has calculated each ramming craft strength which in the ramming process needs, including falls nearby the material strength, the ex-denning strength, the pressure the strength, the drawing strength, the top material strength and so on, and has carried on the reasonable tonnage primary election to the press. The superposable die has used the true thing form in the structure, calculated fell the material, the drawing and the counter- drawing effective range size. Closed has carried on the reasonable determination highly to the mold, but also designs the mold the major parts to fall the material concave mold, the convex-concave mold, the counter- drawing raised mold, the counter- drawing concave mold, the concave mold dead plate and so on. Listed the mold to need the components the detailed detailed list, and has produced the reasonable assembly drawing. Because the drawing depth is big, also carried on the power to the press electrical machinery to examine and to propose the lubrication attachment working procedure, could cause the drawing smoothly to complete. Finally led the wrap to mold major parts to carry on the simple processing craft route formulation. This design regarding uses the single acting press to carry on the pro and con drawing to have the certain reference function.

Key words graduation thesis; mold design; superposable die; pro and con drawing

本次设计中,只对模具中的一个重要零件进行简单的工艺路线的分析,其余的零件将不在具体分析和计算。在这里选择导套为加工对象。

导套、护套及套类凸模均为套类零件,其加工工艺基本相同。导套和导柱一样,是模具中应用最广泛的导向零件。尽管其结构形状因应用部位不同而各异,但构成导套的主要表面是内、外圆柱表面,可根据其结构形状、尺寸和材料的要求,直接选用适当尺寸的热轧圆钢为毛坯。

在机械加工过程中,除保证导套配合表面的尺寸和形状精度外,还要保证内外圆柱配合表面的同轴度要求。导套的内表面和导柱的外圆柱面为配合面,使用过程中运动频繁,为保证其耐磨性,需有一定的硬度要求。因此,在精加工之前要安排热处理,以提高其硬度。

本次设计成功地设计出一副落料、正反拉深复合模,在设计过程中对很多工艺力进行了详细的计算,在压力机的选择上参照了现行选择压力机的通用法则。这次设计解决了采用双动压力机进行正反拉深的传统模式,将落料、正拉深及反拉深同时在一副装在开式单动压力机上的模具中完成,很大程度的提高了生产效率和制造精度。很适合中国现在模具高速自动化发展的趋势。(所有权: 毕业设计网 )

目 录

1 分析零件的工艺性 1

2 确定工艺方案 2

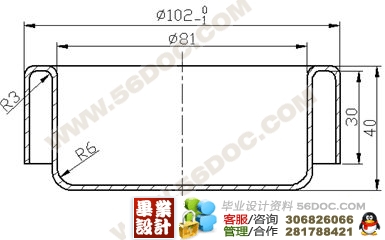

2.1 计算毛坯尺寸 2

2.2 计算拉深次数 4

2.2.1 正拉深 4

2.2.2 反拉深 5

2.3 确定工艺方案 5

3 主要工艺参数的计算 6

3.1 确定排样、裁板方案 6

3.2 确定各中间工序尺寸 8

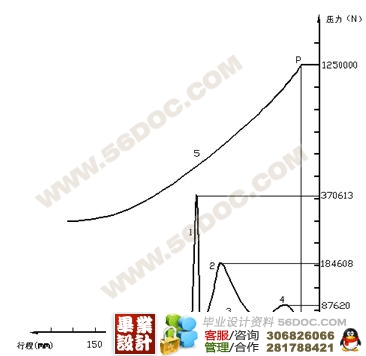

3.3 计算工艺力、初选设备 9

3.3.1 落料、正拉深过程 9

(1) 落料力 9

(2) 卸料力 9

(3) 拉深力 10

(4) 压边力 10

3.3.2 反拉深过程 11

(1) 反拉深力 11

(2) 顶料力 11

3.3.3 拉深功的计算 11

3.3.4 初选压力机 11

4 模具的结构设计 13

4.1 模具结构形式的选择 13

4.2 模具工作部分尺寸计算 13

4.2.1 落料 13

4.2.2 正拉深 15

4.2.3 反拉深 16

5 选用模架、确定闭合高度 16

5.1 模架的选用 16

5.2 模具的闭合高度 16

5.3 压力中心 17

6 模具的主要零部件结构设计 17

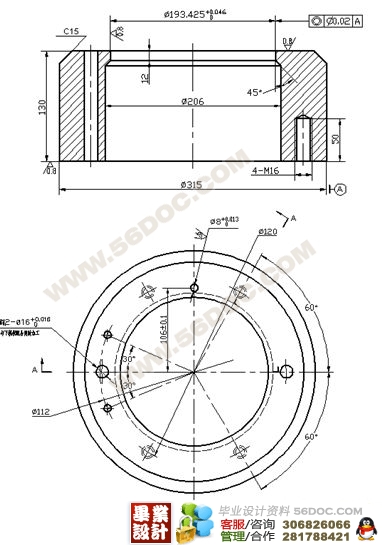

6.1 落料凹模 17

6.2 凸凹模 18

6.3 反拉深凸模 19

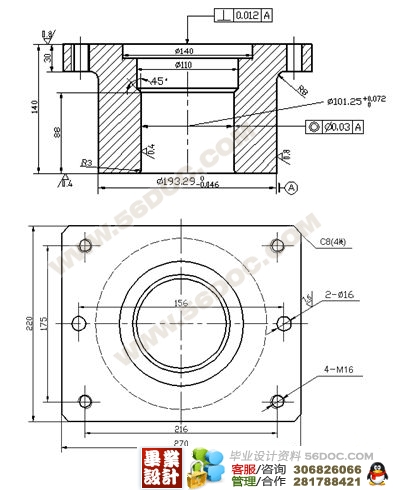

6.4 反拉深凹模 20

6.6 上垫板 23

6.7 凹模固定板 24

(所有权: 毕业设计网 )

7 模具的整体安装 25

7.1 模具的总装配 25

7.2 模具零件 26

8 选定冲压设备 27

8.1 压力机的规格 27

8.2 电动机功率的校核 28

9 附加工序 29

10 主要零件的加工 29

11 总结 32

参考文献 33

致 谢 34

参考文献

[1]郑家贤. 冲压工艺与模具设计实用技术[M].北京:机械工业出版社,2005.

Zheng Jiaxian. Ramming craft and mold design practical technology[M].Beijing: Mechanical industry Press,2005.(in Chinese)

[2]冲模设计手册编写组.冲模设计手册[M].北京:机械工业出版社,1999.

Dies the design handbook compilation group. Dies the design handbook[M]. Beijing: Mechanical industry Press,1999.(in Chinese)

[3]刘心治.冷冲压工艺及模具设计[M].重庆:重庆大学出版社,1995.

Liu Xinzhi. Cold ramming craft and mold design[M].Chongqing: Chongqing University Press,2005.(in Chinese)

[4]卢险峰.冲压工艺模具学[M].北京:机械工业出版社,1997.

Lu Xianfeng. Ramming craft mold study[M].Beijing: Mechanical industry Press,1997.(in Chinese)

[5]周大隽.冲模结构设计要领与范例[M].北京:机械工业出版社,2005

Zhou Dajun. Dies the structural design main point and the model[M].Beijing: Mechanical industry Press,2005.(in Chinese)

[6]中国机械工程学会锻压学会.锻压手册[M].北京:机械工业出版社,2002.

China mechanical engineering academic society forging and stamping academic society. Forging and stamping handbook[M].Beijing: Mechanical industry Press,2002.(in Chinese)

[7]钟毓斌.冲压工艺与模具设计[M].北京:机械工业出版社,2002.

Zhong Yubin. Ramming craft and mold design[M].Beijing: Mechanical industry Press,2002.(in Chinese)

[8]彭建声.简明模具工实用技术手册[M].北京:机械工业出版社,2004.

Peng Jiansheng. Concise mold labor practical technical manual[M].Beijing: Mechanical industry Press,2004.(in Chinese)

[9]模具制造手册编委会.模具制造手册[M].北京:机械工业出版社,1992.

Mold manufacture handbook academic society. Mold manufacture handbook[M].Beijing: Mechanical industry Press,1992.(in Chinese)

|