四分光器上盖注塑模模具设计(包含任务书,论文说明书17500字,幻灯片ppt,cad图纸)

摘要

塑料成型模具是利用特定的形状,通过一定的方式来成型塑料制品的工艺装备或工具。我国的塑料成型模具设计,制作技术比较晚,整体水平还比较低。目前单型腔、简单型腔仍占主导地位。

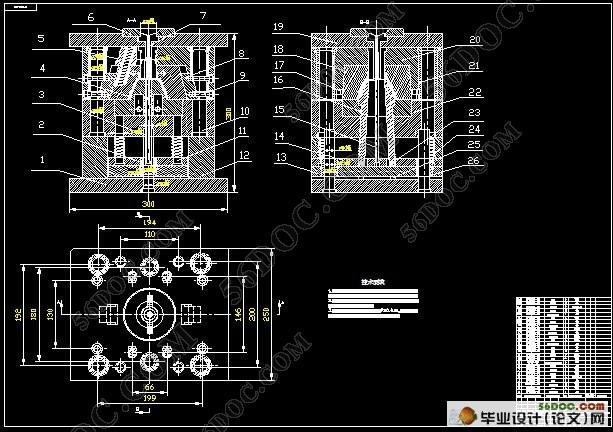

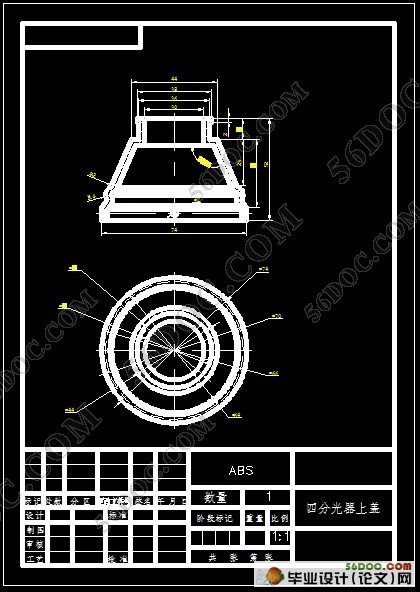

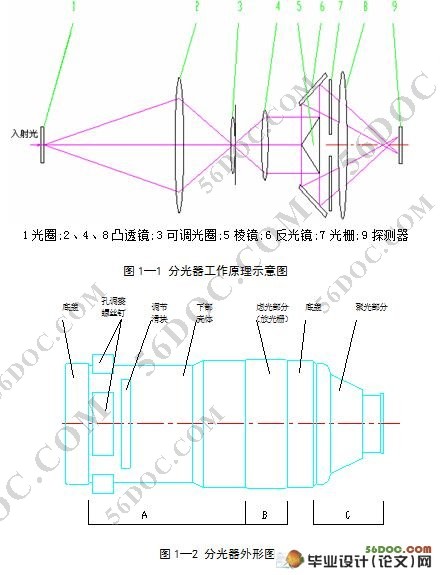

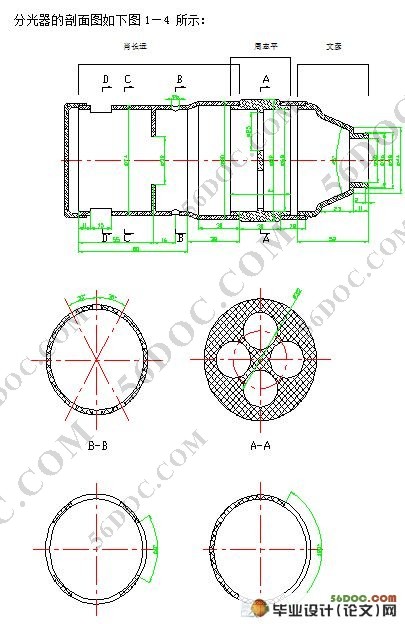

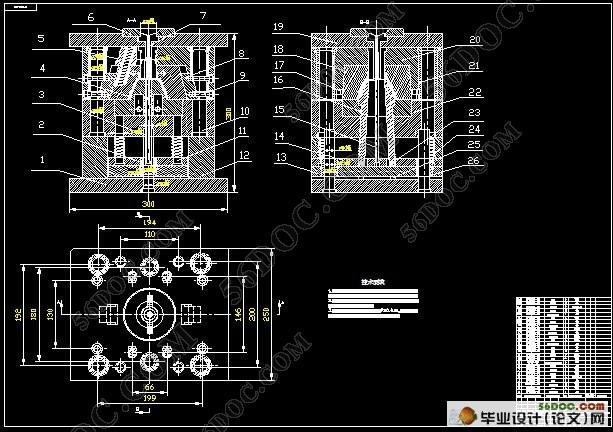

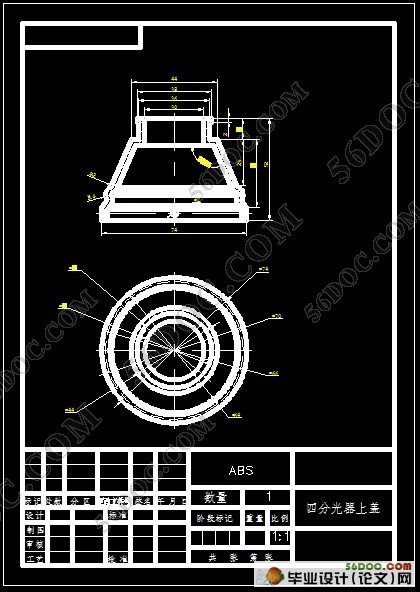

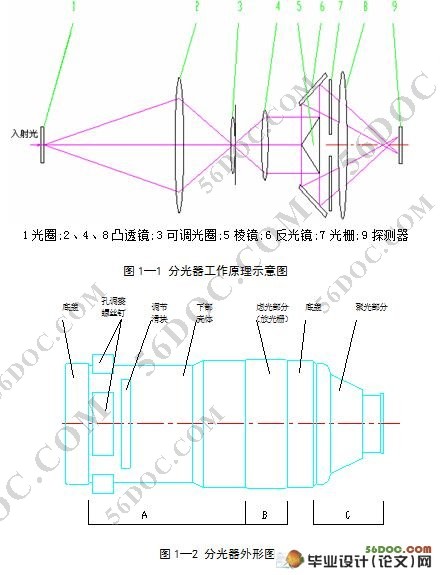

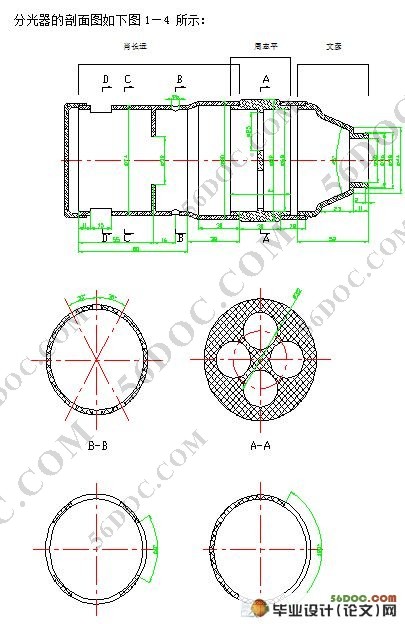

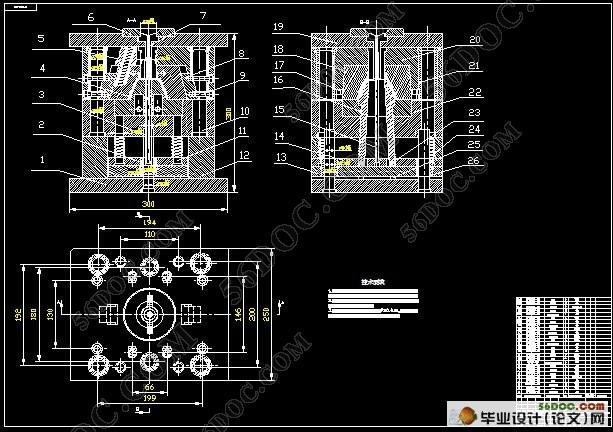

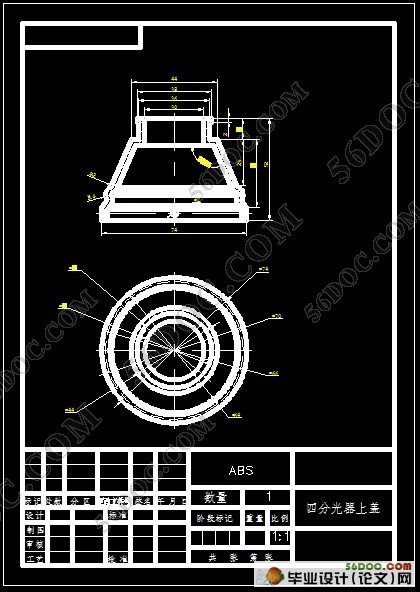

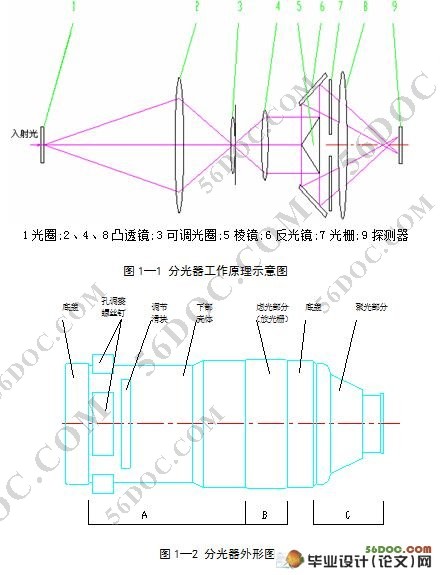

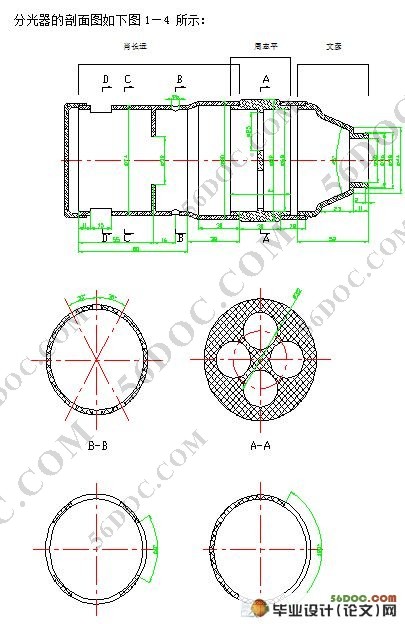

本设计设计出了材料为ABS的四分光器上盖注射模。要设计的塑件是一个壁厚为3mm的零件,因在塑件上侧有凸台、内部有凹槽、下侧有四个小孔,有侧向抽芯,采用斜滑块内侧抽芯,为了便于型芯的加工,采用整体式型芯。本设计对型腔的数量和布局的确定、注射机的选择、流道和冷却系统的设计、模板及其标准件的选用、成型零部件的设计等给出了详细的过程。该模具具有很多优点:结构紧凑、工作可靠、操作方便、运转平稳、冷却效果好、使用寿命长、生产效率高。

关键词:设计;整体式型芯;抽芯;推杆;注射模

Abstract

The plastic model was a kind of technological equipment or instrument which was made into particular shape to form plastic products by specific way. Because the design and making of plastic die developed lately in our country, the level of design die in our country is rather low compared to the developed country. At present the single or sample cavity occupies dominate position.

The design of materials designed for ABS cover a quarter of optical injection mold. Must design models is a wall thickness is the 3mm components, Because in models a on side to have the lug boss, the interior has the scoop channel, the breast has four eyelets, has laterally pulls out the core, uses the slanting slide rod inside to pull out the core, for ease of the core processing, uses the integral type core. The detail declaration for the every process was mainly included the determination of the lay-out and quantity of the cavity, the chosen of the injective machine, the design of the feed inlet and the coolant system, the selects of the follow and its standard letter ,the design of the spare part for taking shape and so on. There are many advantages in the dies, such as compact-structure, credibility-working, convenient-manipulation, steady-revolution, high-cooling-effectiveness, long-life, high-production-coefficient, and high-accuracy-standard and so on.

Keywords: Design; integral type core; Loose core; Push pole; Injection die

|