塑料接线扣环模具的设计

来源:wenku163.com 资料编号:WK1633523 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK1633523

资料介绍

摘 要

塑料工业是当今世界上增长最快的工业门类之一,而注塑模具是其中发展较快的种类,注射模技术的不断发展需要越来越多的工艺流程,注射成型过程中最重要的问题毫无疑问是注射模具的正确设计,因为成型车间对注射模具的影响很小,即便有,也是对机器的结构有影响的,因此,研究注塑模具对了解塑料产品的生产过程和提高产品质量有很大意义。

本设计介绍了注射成型的基本原理,特别是单分型面注射模具的结构与工作原理,对注塑产品提出了基本的设计原则;详细介绍了冷流道注射模具浇注系统、温度调节系统和顶出系统的设计过程,并对模具强度要求做了说明;计算机辅助设计/计算机辅助制造是指为了提高生产率让计算机参与设计和制造产品的过程;最后介绍了当今世界上最为普及的三维CAD/CAM系统标准软件PRO/ENGNEER的PROGRAM模块,对导柱和导套进行了参数化设计。

通过本设计,可以对注塑模具有一个初步的认识,注意到设计中的某些细节问题,了解模具结构及工作原理;通过对PROGRAM的学习,可以建立较简单零件的零件库,从而有效的提高工作效率。

关键词:塑料模具;镶件;侧抽芯;分型面

Abstract

Plastic industry is in the world grows now one of quickest industry classes, but casts the mold is development quick type, The continuing development of injection mold technology demands more and more of the processes. The most important problem in the process of injection molding is undoubtedly the correct design of injection mold, because the molding shop has little influence,if any, on the construction of the machine. Therefore , the research casts the mold to understand the plastic product the production process and improves the product quality to have the very big significance.

This design introduced the injection takes shape the basic principle, specially single is divided the profile to inject the mold the structure and the principle of work, to cast the product to propose the basic principle of design; Introduced in detail the cold flow channel injection evil spirit mold pours the system, the temperature control system and goes against the system the design process, and has given the explanation to the mold intensity request; Computer aided design/ computer aided manufacturing (CAD/CAM) refers to the integration of computer into the design and production process to improve productivity; Finally introduced now in the world the most popular three dimensional CAD/CAM system standard software PRO/ENGNEER' s PROGRAM module, and led the wrap to the guide pillar to carry on the parametrization design.

Through this design, may to cast the mold to have a preliminary understanding, notes in the design certain detail question, understands the mold structure and the principle of work; Through to the PROGRAM study, may establish the simple components the components storehouse, thus effective enhancement working efficiency.

Key word: The plastic mold; inlays; Side core pulling ;divides the profile

目 录 15000字

摘 要 3

1.引言 5

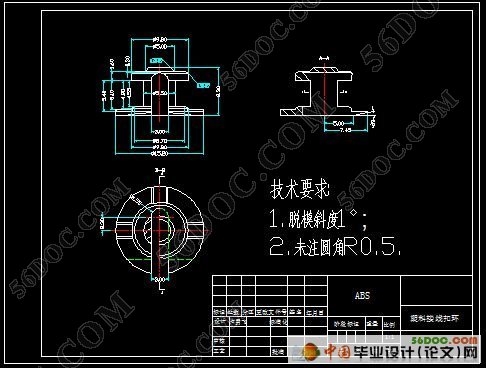

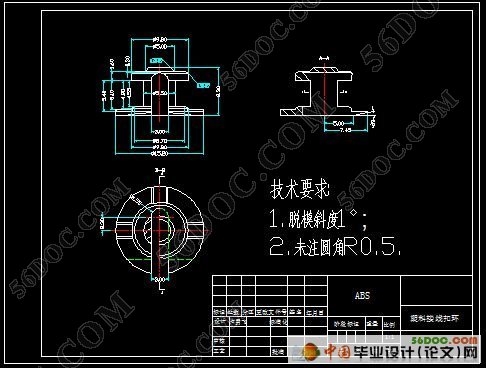

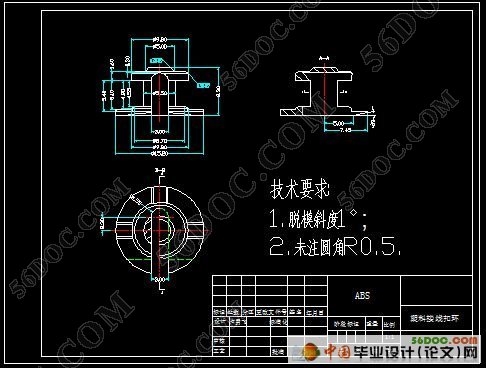

2 塑件分析 6

2.1塑件图 6

2.2材料分析 7

3 分型面的设计 8

3.1分型面的形式: 8

3.2分型面的选择和型芯材料选择: 9

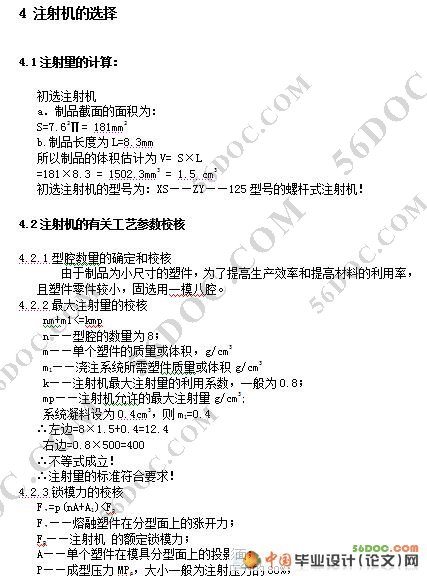

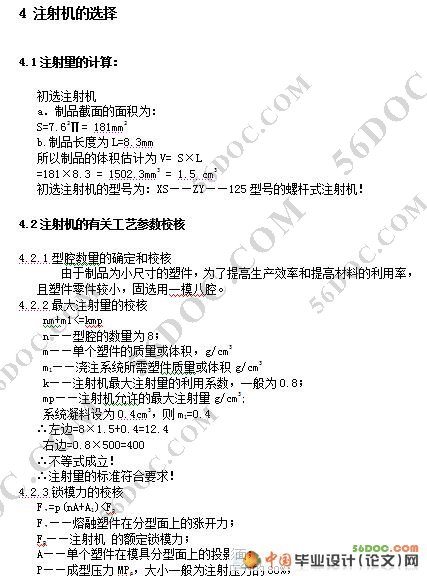

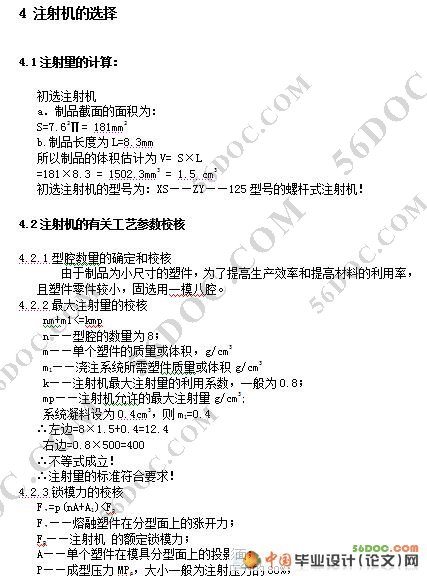

4 注射机的选择 9

4.1注射量的计算: 9

4.2注射机的有关工艺参数校核 10

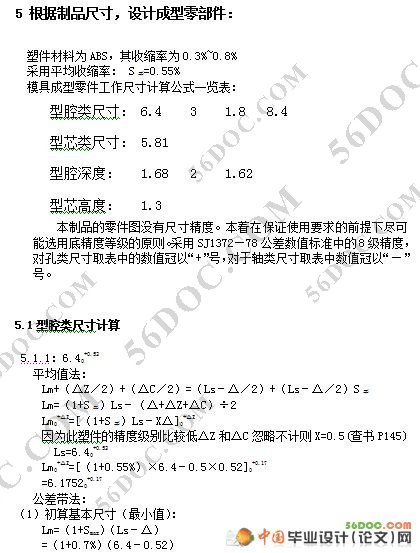

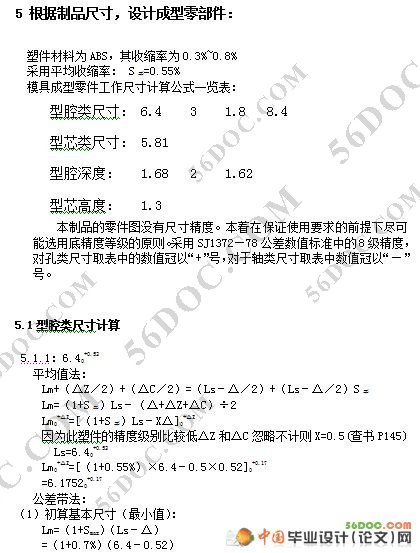

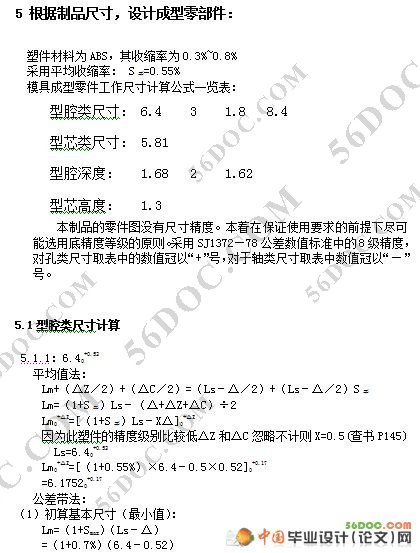

5 根据制品尺寸,设计成型零部件: 12

5.1型腔类尺寸计算 13

5.2型芯类尺寸计算 15

5.3型腔深度计算: 16

5.4型芯高度计算: 17

6 型腔壁厚计算 18

6.1型腔选用矩形整体式腔如下图: 18

6.2计算 20

7 浇注系统的设计 20

7.1主流道的设计 21

7.2分流道的设计 21

7.3浇口的形状 23

7.4浇口位置的选择 23

7.5浇注系统的平衡 23

8 推出机构设计 24

8.1推出机构的设计要求: 24

8.2推出力的计算 25

8.3推杆形状的设计及其固定形式 25

8.4推杆位置的选择 26

8.5复位机构 26

9 导向机构的设计 26

9.1导向、定位机构的作用 26

9.2导向、定位机构的总体设计 26

9.3导柱的结构与设计 26

9.4导套的结构与设计 27

9.5导柱和导套的配用 28

9.6模架的选择 28

10.侧向分型与抽芯机构设计 29

10.1机动式侧面分型抽芯机构 30

10.2斜导柱侧向分型抽芯机构的设计 30

10.3斜滑块的设计 33

10.4楔紧块的设计 33

11温度调节系统 34

11.1冷却系统的设计 34

11.2加热系统的设计 36

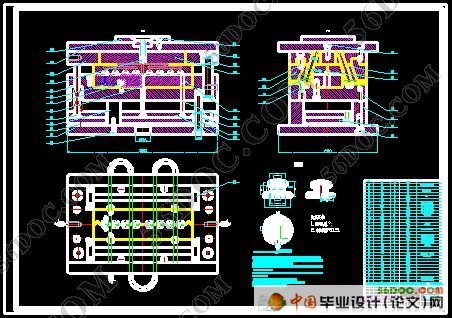

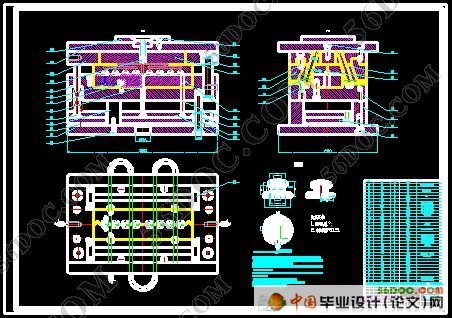

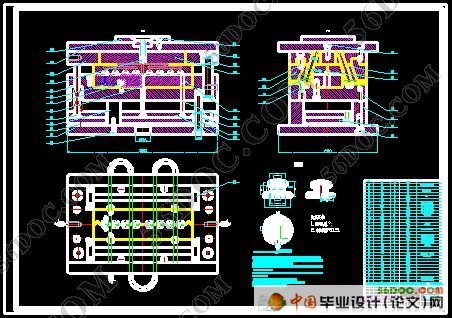

12 模具的装配 36

13 试模 37

13.1试模前的准备 37

13.2试模 37

14.结论 39

谢 辞 40

参考文献 41

|