无凸缘圆筒形件的落料-拉深复合模具设计(含工艺卡片)

来源:wenku163.com 资料编号:WK1633542 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK1633542

资料介绍

无凸缘圆筒形件的落料-拉深复合模具设计(含工艺卡片)(含任务书,开题报告,中期检查表,毕业论文说明书12000字,cad图纸7张零件图1张装配图)

摘要

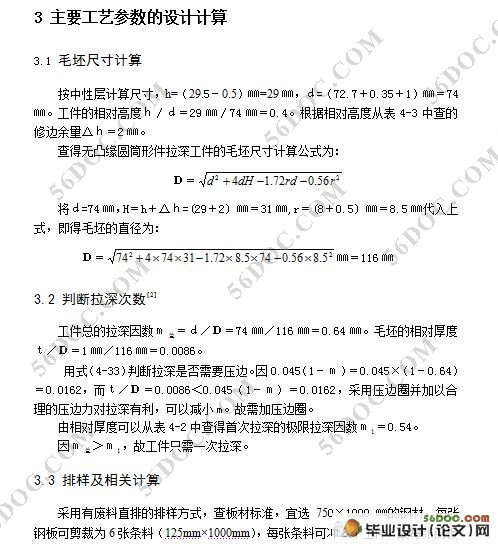

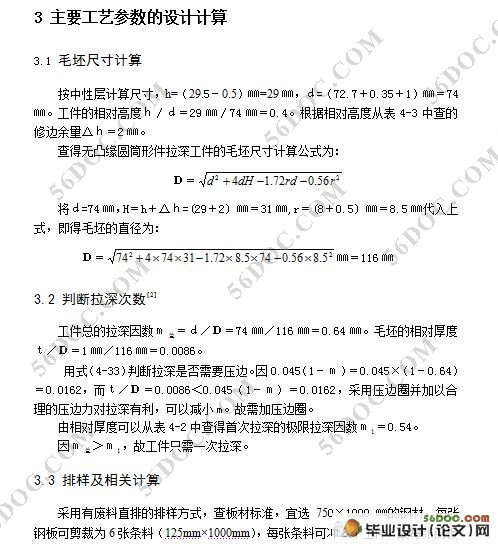

以无凸缘圆筒形工件为例,结合其模具设计特有工艺性,进行了工艺性分析,并分析了成形过程的三种不同的冲压工艺方案,从理论探讨及实验上提出了最佳工艺方案。介绍了模具设计要点。介绍了冲压工艺分解过程、排样图、模具结构分析、工作原理;并对模具的各部分主要尺寸进行理论运算,以确定各冲模的尺寸;对落料—拉深模具从设计到零部件的加工工艺以及装配工艺等进行了详细阐述,简要分析了模具关键零部件的设计及加工工艺。实践证明,模具结构能很好地满足零件的精度要求,不仅模具结构左右对称,受力均匀,而且生产效率高。

关键词:工艺性分析 落料—拉深复合模 装配工艺

Abstract

Taking type or paste here to translate text as an instans,combining with its special of die design,the process analysis ,and three kinds of different stamping technique plans were analyzed, optimal processing plan and feasible forming die were obtained according to theoretical analysis and experiment. The critical points of die design are introduced.The decomposing process of punching,layout,die structure analysis are carried out,woek principle;and the theoretical calculation to the main dimensions of die are carried out so as to determine the size of different punching dies; the die design and the process of parts as well as the assembling process and blanking-drawing compound die are stated in details,the design and manufacture process of the key part of the die were also discussed in brief. Practical application showed,that the die structure could meet the require meet the spare parts accuracy ,not only are the die structure and force condition symmetrical,but also the production efficiency is hign.

Key words: processing analysis blanking-drawing compound die assembling process

插图清单

图 3.5.1 通气孔的结构示意 ……………………………………………………9

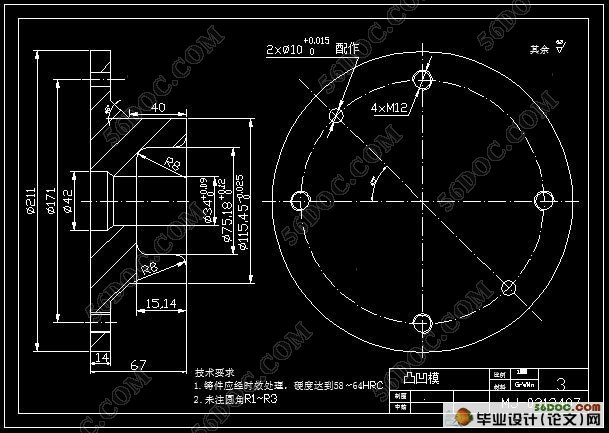

图5.1.1 拉深凸模 ……………………………………………………………11

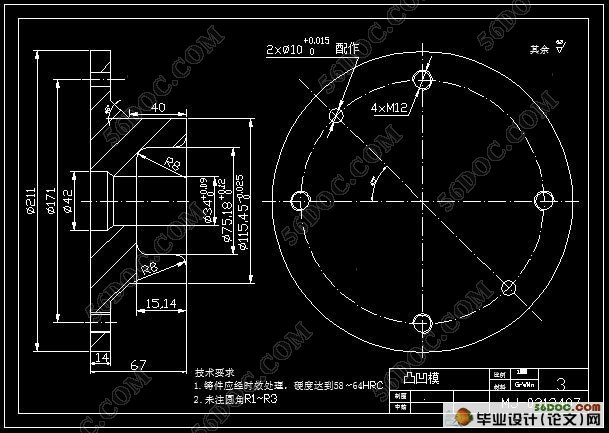

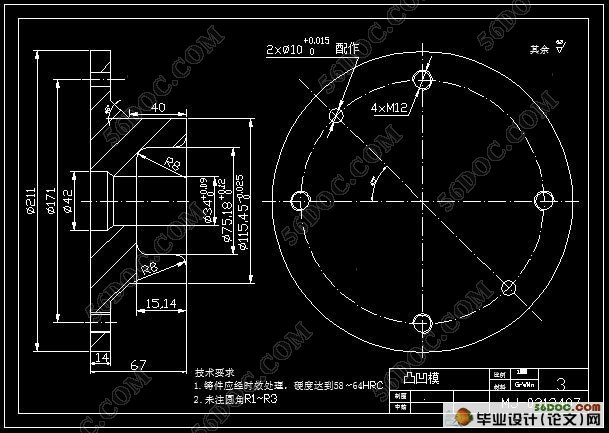

图5.1.2 落料凹模 ……………………………………………………………12

图 5.1.3 凸、凹模 ……………………………………………………………12

图5.2.2.1 压边圈的结构形式 ……………………………………………………14

图5.3.4.1 推件块的结构示意图 …………………………………………………15

图 5.2.2.1 上模垫板的结构示意图 ……………………………………………16

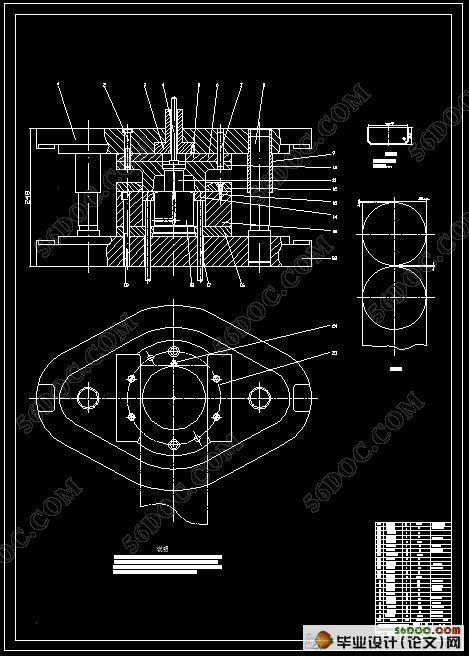

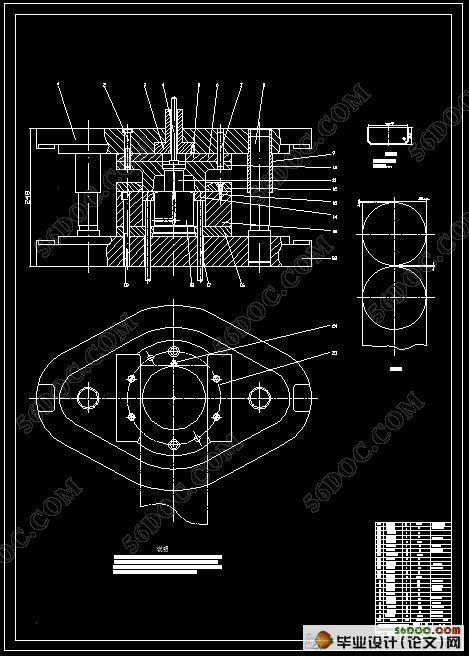

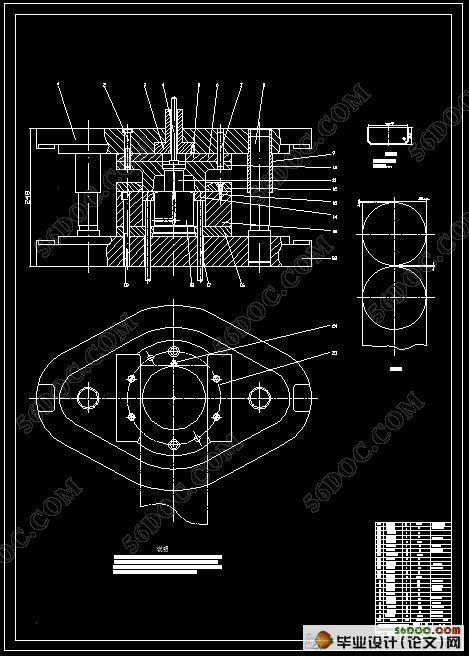

图7.1模具的装配图 ……………………………………………………………20

|