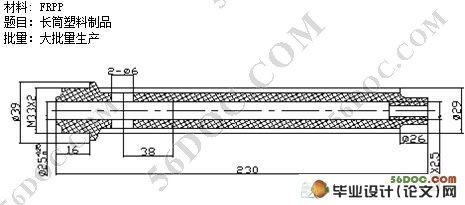

长筒注塑成型工艺与模具设计(附加工工序卡)(含任务书,开题报告,中期检查报告,毕业论文说明书16000字,cad图6张)

摘 要

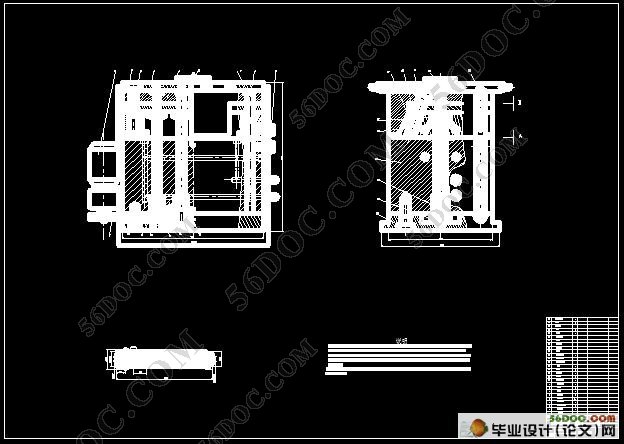

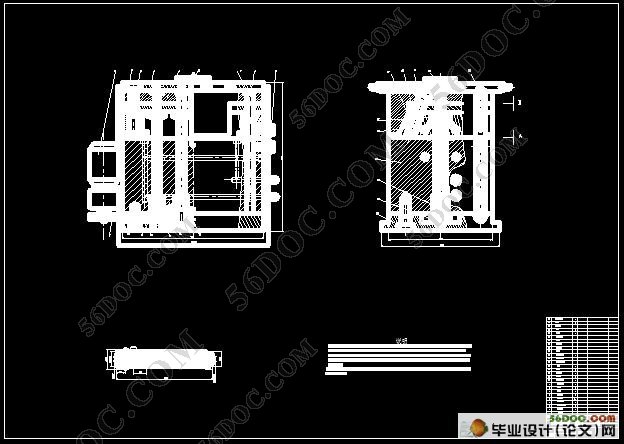

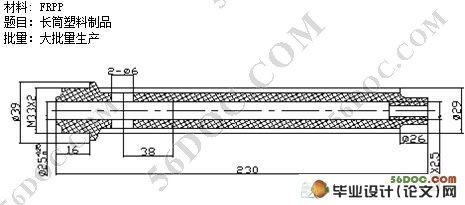

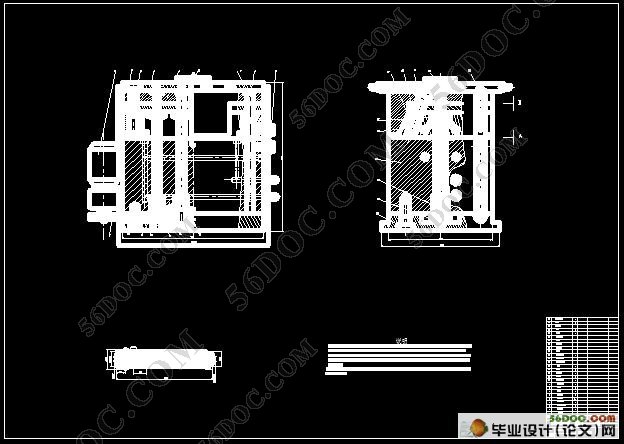

本设计的题目是支承盘注塑成型工艺与模具设计,从图纸上分析,该零件总体形状为圆盘形。外形结构比较简单,但内,所以成型收缩后必留于型芯上。所以型腔应设计在定模一侧,型芯设计在动模上,由于制件没有侧孔,所以不需侧抽芯,采用直接抽芯即可。

根据塑件的特点,模具型芯在动模部分。开模后,塑件应收缩包紧型芯,而

留在动模部分,其推出机构采用推件板与顶管联合推出的推件方式。该种脱模方式是在分型面处从壳体塑件的周边推出。推出力大且均匀。对侧壁脱模阻力较大的薄壁箱体或圆筒制品,推出后外观上不留痕迹。

对合导向机构的功能三保证动定模部分能够准确对合,使分别加工在动模和定模上的成型表面在模具闭合后形成形状和尺寸准确的腔体,从而保证塑件形状,壁厚和尺寸的准确,该模具采用导柱对合导向机构。导柱和型芯一起安装在动模一侧,这样在合模时可起保护作用。

相信不久本模具投入市场一定能带来很好的效益服务大众,服务社会。

关键词: 塑料 模具 凸模 推件板

Suppers disc shaped crafts and die design molded plastic parts

This design topic is the pressed key components plastic note molds the design, analyzes from the blueprint, this components overall shape is a rectangle. Has 3 rectangular in the length direction the different shape holes, is easy to take shape. Looked from wall thickness that, the wall thickness most main point is the 1.5mm most narrow view is the 1.2mm wall thickness is even, is advantageous to components taking shape.

According to models a characteristic, the mold core is moving the mold to be partial. After operates the mold, models to be supposed to contract male ,but

Remains moves the mold to be partial, it promotes the organization to use pushes a board to promote pushes a way. This drawing of patterns way is peripheral models in a minute profile place from the shell to promote. Promotes the strength big also is even. To the sidewall drawing of patterns resistance big thin wall box body or the cylinder product, after promotes seemingly not the scar.

The involution guidance organization function three guarantees moves decides the mold to be partial can the accurate involution, causes to process separately in moves the mold and decides on the mold to take shape the surface closed to form the shape and the size accurate cavity body after the mold, thus guaranteed models a shape, wall thickness and size accurate, this mold uses the guide pillar involution guidance organization. The guide pillar and the core installs together in moves a mold side, like this when gathers the mold may get up the protective function.

Believed this mold invests the market certainly to be able soon to bring the very good benefit service populace, the service society.

Critical word:plastic Model Male Ejector plate

内容:(1)模塑工艺规程的编制

(2)确定分型面

(3)浇注系统的确定

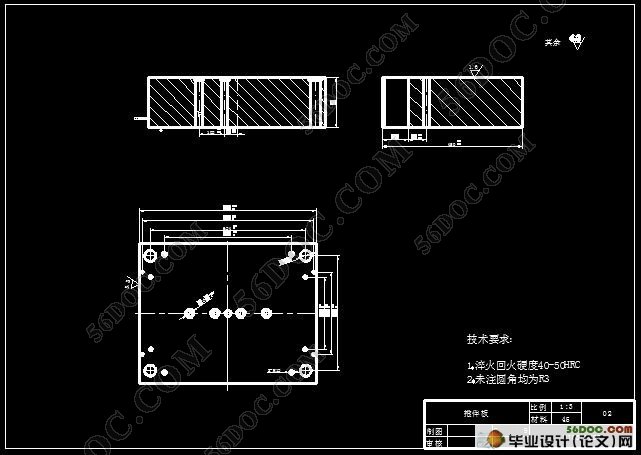

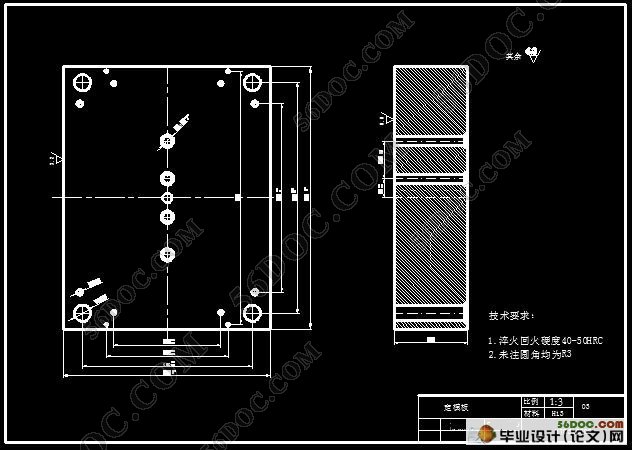

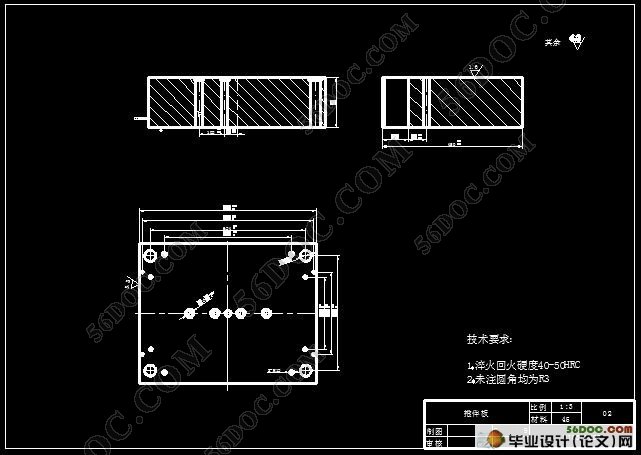

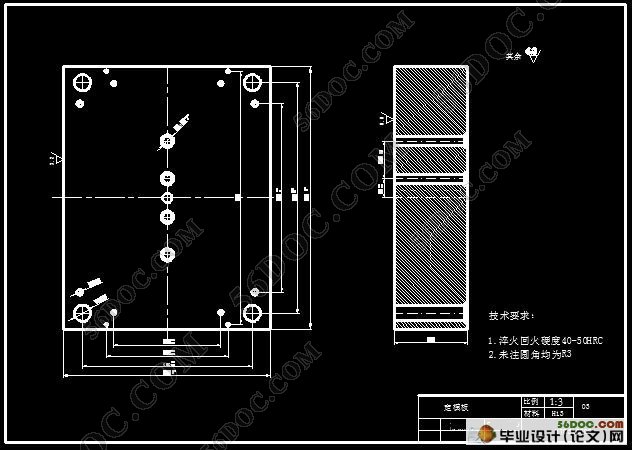

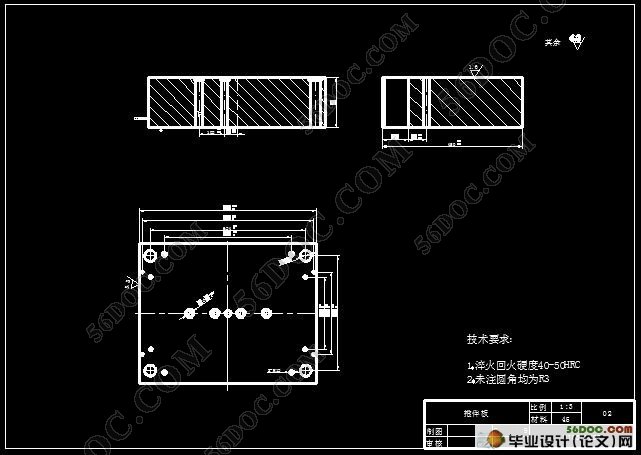

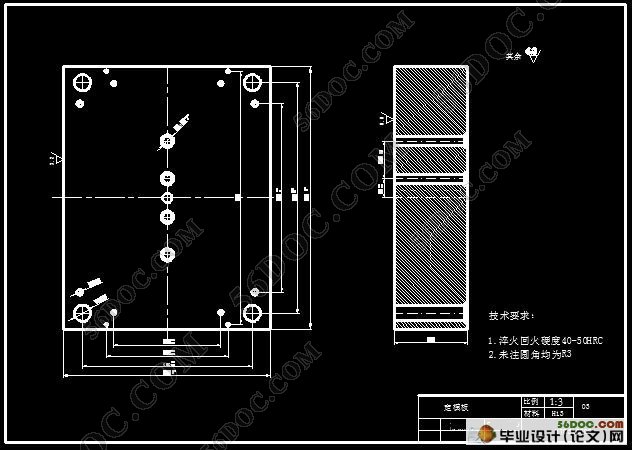

(4)成型零件的结构设计

(5)成型零件的结构设计

(6)冷却加热系统的设计

原始资料:

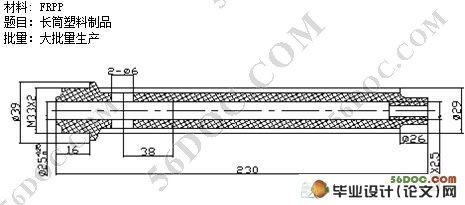

设计题目:长筒注塑模

材料:FRPP

生产批量:大批量生产

查找相关文献和参考,玻璃纤维增强聚丙烯的成型工艺参数可作如下选择:(试模时,可根据实际情况作适当调整)

注塑温度:包括料筒温度和喷嘴温度。

料筒温度:后段温度选用165°C

中段温度选用250°C

前段温度选用185°C

喷嘴温度:选用185°C

模具温度:70°C~90°C

注塑压力:90~130Mpa

注塑时间:0~30s

保压时间:选用15~30s

冷却时间:选用15~30 s

成型周期:40~90 s

插图清单

图1 分型面的选择……………………………………………………………………9

图2 型腔的排列 ……………………………………………………………………10

图3 分流道的结构 …………………………………………………………………12

表格清单

表1 塑件的原材料分析………………………………………………………………4

表2 ABS的注射成型的工艺参数 …………………………………………………7

表3 工作尺寸的取值规定 …………………………………………………………16

表4 成型零件工作尺寸的计算 ……………………………………………………17

|