接头冲压成形工艺及模具设计(附加工工艺卡)

来源:wenku163.com 资料编号:WK1633573 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK1633573

资料介绍

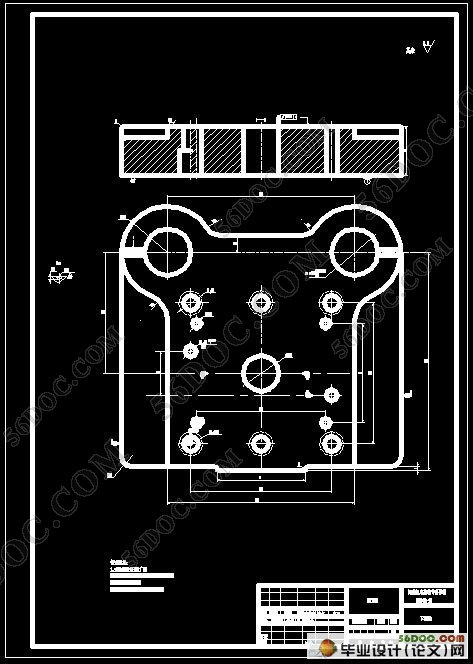

接头冲压成形工艺及模具设计(附加工工艺卡)(含任务书,中期检查报告,毕业论文说明书15000字,cad图纸19张合一)

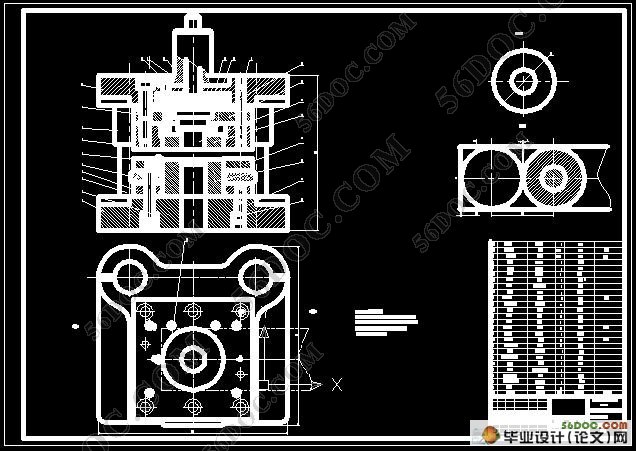

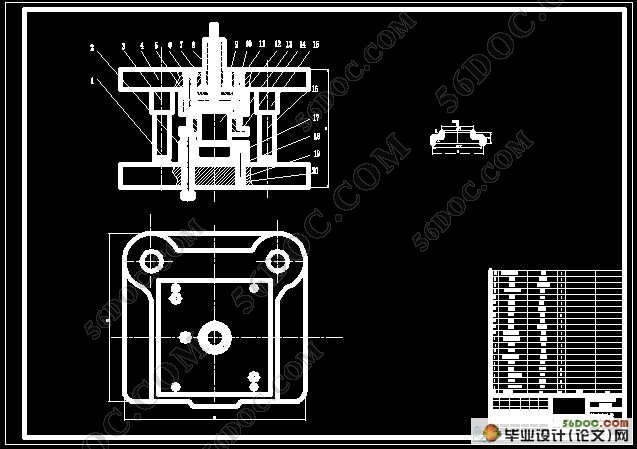

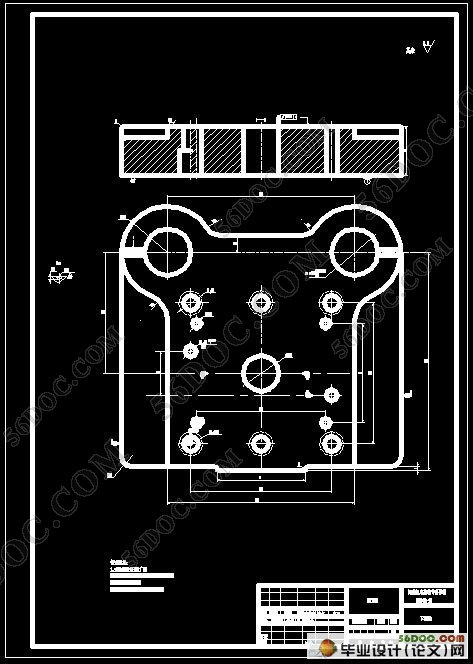

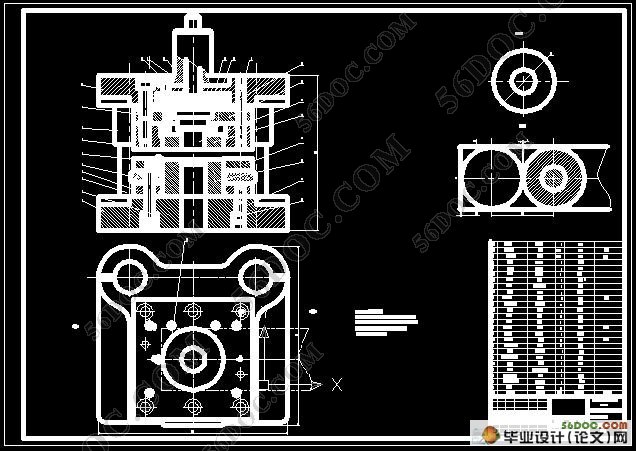

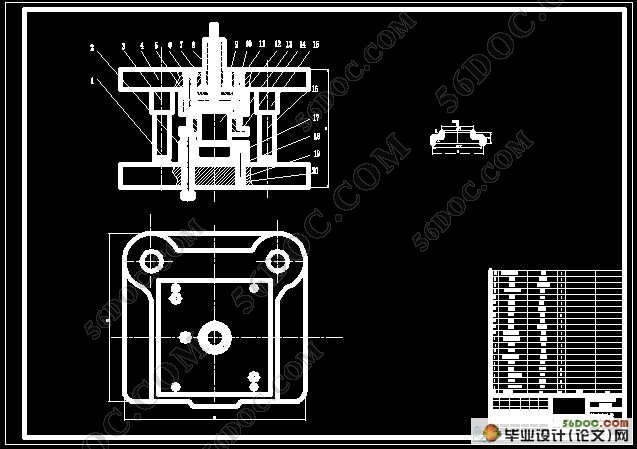

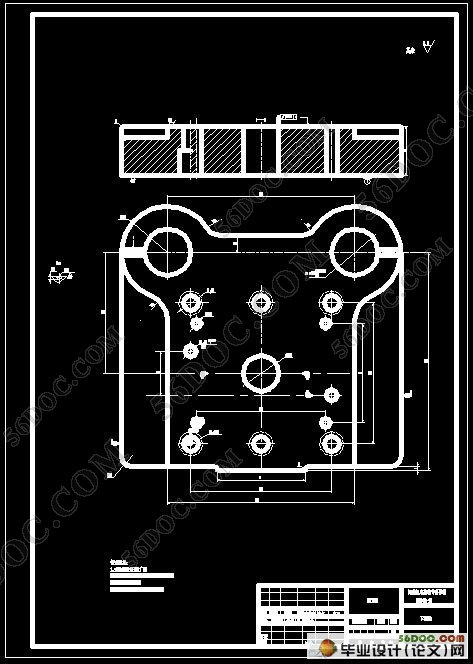

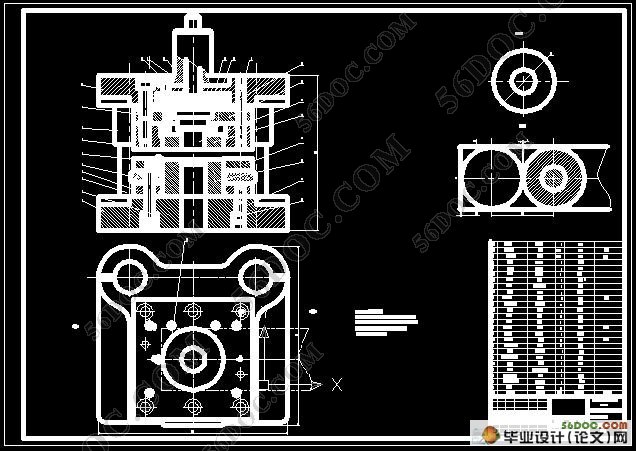

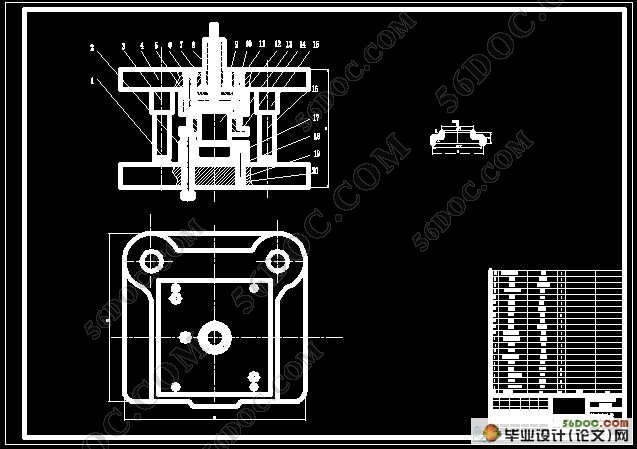

摘要:设计着重介绍了制件的成型工艺,及模具结构设计。通过对制件的工艺分析,确定了工艺方案。并设计了一套倒装复合模具。在设计同时利用参考资料,确定了各工作零件的尺寸。并较多的考虑了模具结构的调整性、易更换性及模具成本。同时在模具设计内容中融汇了冲压模具的不同加工方法、加工工艺及装配工艺,对初学冲压模具模设计者有一定的参考价值。本设计从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词: 翻边模 复合模 拉伸模

joint pressing formed technology and mold design

Abstract: The design introduced emphatically the workpiece takes shape the craft, and mold structural design. Through to the workpiece craft analysis, has determined the craft plan. And has designed set of true things compound molds. Uses the reference during the design, has determined each work components size. And many considerations mold structure adjustment, easy replacement and mold cost. Meanwhile has blended together the ramming mold different processing method in the mold design content, the processing craft and the assembly craft, to begins studies the ramming mold mold designer to have the certain reference value. This design designs from the mold to the spare part processing craft as well as the assembly craft and so on carries on the detailed elaboration, and carries on each important components using CAD the design.

Key words: the turn down dims mold the compound mold.

工件名称:接头

生产批量:中批量

材料:冷轧08钢

厚度:1.5mm

对固定套翻边件进行分析可知, 处有内孔翻边成形,翻边前应预冲孔, 是圆筒件拉深件直径,经计算可一次拉深成形。工序安排为落料,冲孔,拉深,翻边。

该零件形状简单、对称,是有圆弧组成的。冲裁件内外形所能达到的经济精度为IT11 ~IT14,孔中心与边缘距离尺寸公差为 .将以上精度与零件的精度要求相比较,可认为该零件的精度要求能够在冲裁加工中得到保证,其他尺寸标注、生产批量等情况,也均符合冲裁的要求,故决定采用冲压方式可以得到落料、冲孔、拉深件,然后进行翻边得到制件。

|