端盖注射模的设计(含cad零件图和装配图)(含选题审批表,任务书,开题报告,中期检查表,论文说明书17000字,CAD图纸17张)

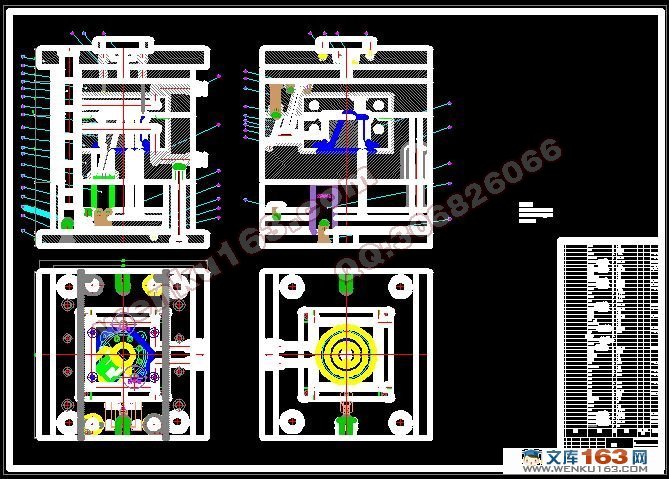

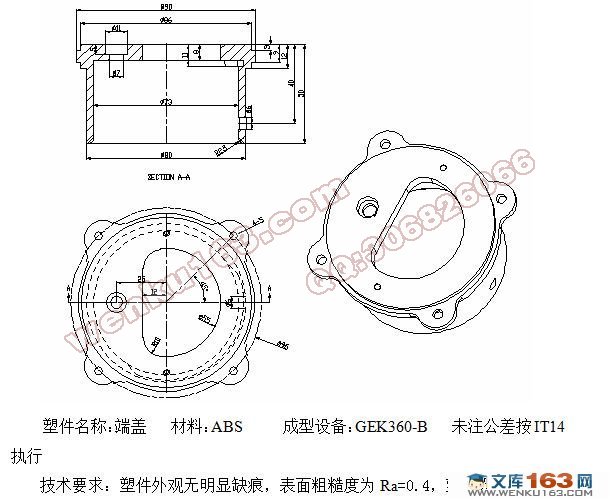

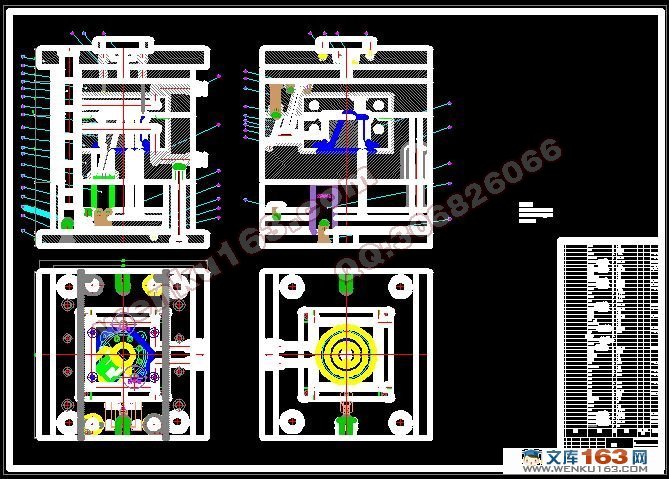

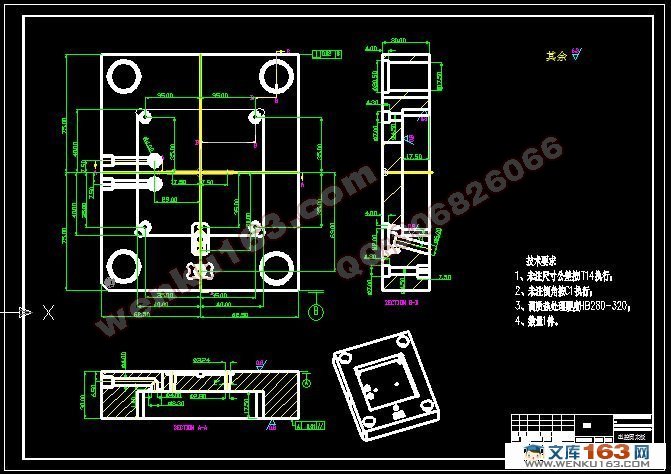

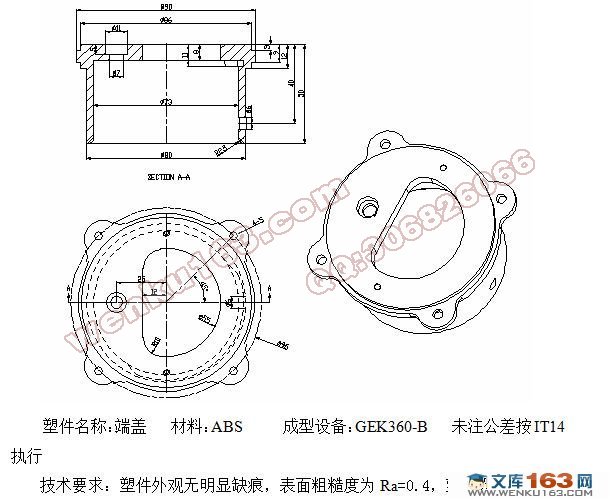

摘 要:首先对所要设计的产品进行工艺的分析与计算,该塑件采用由丙烯、丁二烯、苯乙烯三种单体共聚而成的ABS为材料,然后在分析计算的基础上确定成型工艺 方案,为一模一腔,推杆推出,点浇口,单分型面,浇口套内的主流道采用圆锥形,选用的模架为标准模架,导柱导套的安装用Z1的安装方式,再在此基础上进入 模具总装配图的结构设计以及尺寸的确定。在此基础上对注塑模具的主要零部件尤其是成型零部件的尺寸进行设计与计算,期间要参考塑料成型相关的资料和翻阅各 种塑料模具设计手册,并通过计算以确定模具的具体结构及尺寸以及成型零件的相关尺寸,通过不断的计算与修改,并在指导老师的悉心关怀和耐心指导下进行不间 断的反复修改,最终独立完成这次毕业设计。在设计的过程中,主要成型零件采用镶拼结构,利于加工。另外,本次毕业设计是对我大学所学各种知识的综合检验和 考查,通过这次毕业设计使我了解和掌握了许多更深层的知识,并且整个过程都是自己独立完成的,提升了自己的能力,在整个设计过程中,详细介绍了塑件材料的 基本特性和成型特点,模具的结构组成、结构特点、工作原理、设计原理、注塑机相关参数、模具材料和热处理要求等。其中对浇注系统、成型零部件、结构零部 件、推出机构、冷却系统、排气系统作了重点阐述。

关键字:注塑模;浇注系统;侧浇

Design of Cover Injection Mould

Abstract: First to design of the product process analysis and calculation, the plastics used by the propylene, butadiene styrene three monomers copolymerization and become ABS for material, then on the basis of the analysis and calculation to determine molding process solutions for exactly a cavity, push rod launch, point runner, single parting surface, runner set inside the mainstream way adopts cone, selection of formwork for standard formwork, guide pin guide with the installation of Z1 installation way, and on the basis of this total into the mold of assembly structure design and size determination. On the basis of the main parts especially injection mold size discusses h0 during the design and calculation, the plastic molding related to reference through all kinds of plastic material and mould design manual, and through the calculation to determine the specific structure and size mold and molding parts related size, through continuous calculation and modification, and in guiding teacher of meticulous care and patience under guidance of uninterrupted repeated revision, eventually independent completed the graduation design. In the design process, the main forming parts adopt insert or structure, beneficial to the processing.

In addition, the graduation design is learned in my university of knowledge comprehensive inspection and examination, pass the graduation design makes me understand and master the many deeper knowledge, and the whole process is done independently, promoted oneself ability, in the whole design process, introduces the basic characteristics of molded parts material and forming characteristics, die structure composition, structure characteristics, working principle, design principle, the injection molding machine relevant parameters, mould material and heat treatment requirements, etc. Among the gating system, molding parts, structure parts, launch institutions and exhaust system, cooling system, and presented.

Key word: injection mould; gating system; side gate

目 录

摘要 1

关键字 1

1 前言 2

2 塑件工艺分析 3

2.1 塑件原材料的分析 4

2.2 塑件结构和尺寸精度、表面质量分析 5

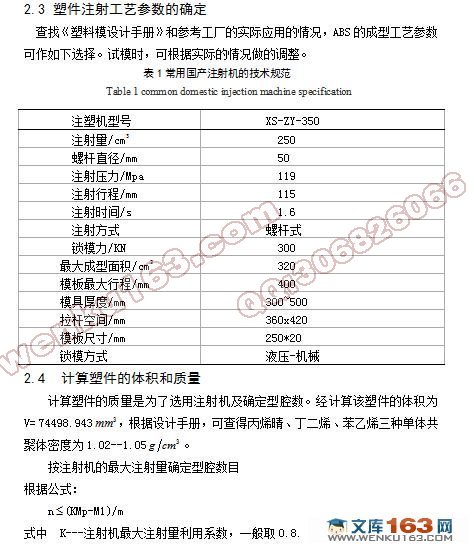

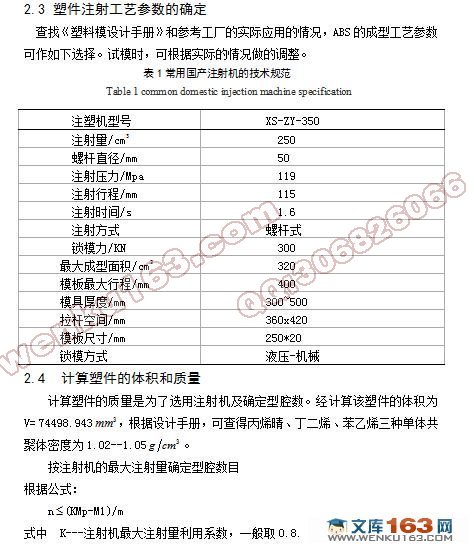

2.3 塑件注射工艺参数的确定 5

2.4 计算塑件的体积和质量 5

3 成型方案及模具类型 6

3.1 确定模具类型 6

3.2 确定模具类型的主要结构 8

3.2.1 分型面的选择 8

3.2.2 型腔的排列方式的确定 9

3.2.3 浇注系统的设计 10

3.2.4 排气系统的设计 16

4 脱模机构设计 16

5 推出机构的设计 17

6. 冷却系统的设计 19

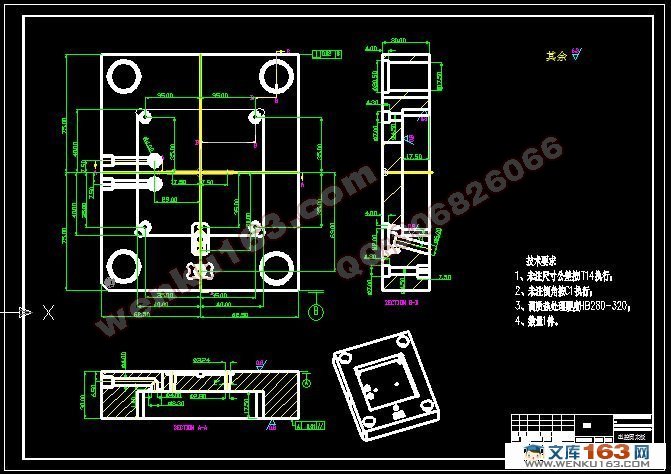

7. 成型零件的设计 22

7.1 成型零件的结构设计 22

7.2 成型零件的工作尺寸计算 23

7.2.1 影响塑件尺寸精度的因素 23

7.2.2 成型零部件工作尺寸计算 24

8 抽芯机构的设计 26

8.1 侧向分型与抽芯方式 26

8.2 侧向分型与侧抽芯机构的类型的选用 26

8.2.1 斜导柱侧抽芯机构的工作原理 26

8.2.2 斜导柱侧抽芯机构的组成形式 27

8.3 斜导柱的侧抽芯机构设计 28

8.3.1 斜导柱的设计 28

8.3.2 滑块的设计 29

8.3.3 楔紧块的设计 30

8.4 斜顶的设计 31

9 塑料模材料及选用 31

9.1 模具成型零件对材料的要求 31

9.2 塑料模材料 32

10 注塑模在注射机上调试及试模 35

10.1 注射机有关参数的校核 35

11 结论 35

参考文献 36

致谢 37

|