简易模具结构毕业设计

来源:wenku163.com 资料编号:WK1638017 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK1638017

资料介绍

简易模具结构毕业设计(论文说明书3500字,cad图纸14张)

摘 要

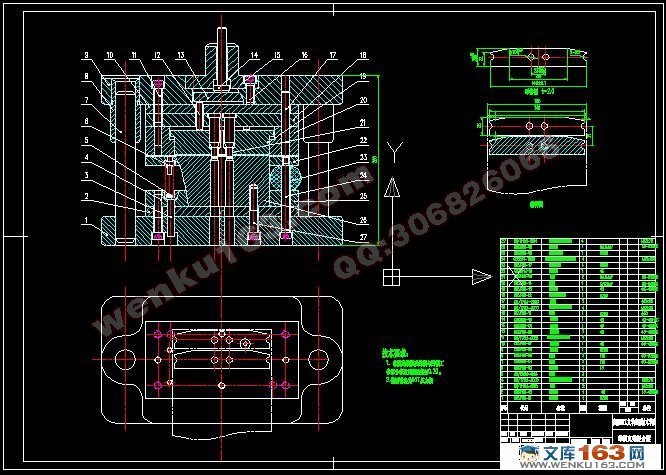

本设计着重对模具结构的设计,因为冲模结构是冲模设计的灵魂,它不仅决定了模具的功能,同时也决定了模具开发的成本和制造周期及操作的安全性。

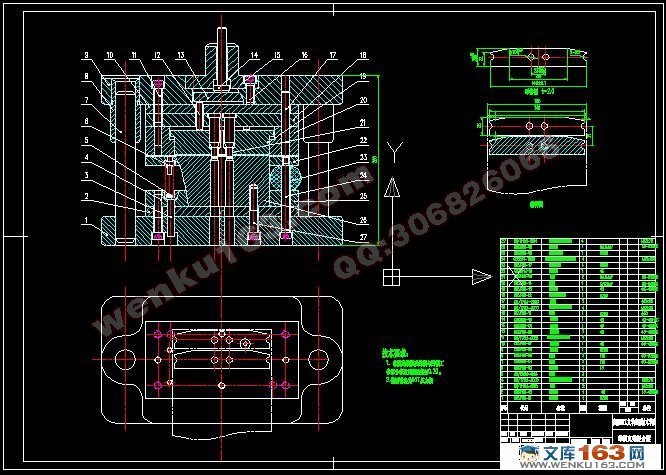

本模具凹模采用整体式的结构,便于制造和维护:模具的落料凸模用固定板固定,便于调整间隙;落料凹模则采用螺栓固定在下模座上。落料凹模上装有导料销和挡料销,保证了工件尺寸和外形的精度准确,提高了加工精度。如此设计出的结构可确保模具工作运行可靠和冲压产品大批量生产的要求。

关键词:复合模 冲孔 落料 成型模

Abstract

The design of the blanking and punching, drawing composite modulus design. This paper briefly outlined the stamping sie current development status and trends. The product of a detailed analysis and the identification process.stamping die design in accordance with the general steps to calculate and design the sets on the main mold parts, such as : punch and die. Punch plate, plate, Die plate and dump plates . feet behind the sales, marketing and other derivative is. Die-standard model planes, to choose a suitable stamping equipment. Design work on the parts and

specifications will press for the necessary checking calculation. In addition, the die block used only with marketing materials and Crook block behind the marketing materials. Punch and Die blanking punch were different plate fixed to facilitate adjustment gap; Punch and Die blanking die is used overall fixed plate. Blanking punch contents is a derivative sales, and guarantee the workpiece and the shape of the holes in the relative position accurately, improve processing accuracy. So the structure is designed to ensure reliable operation of die stamping products and mass production requirements.

Keywords : Gang dies Pierce Blanking Forming die.

目录

摘 要 I

Abstract II

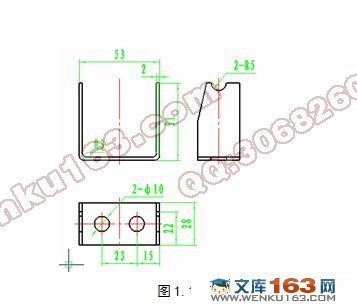

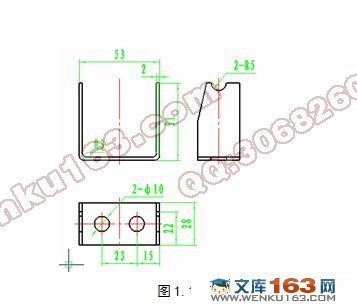

1零件的工艺分析 1

1.1 公差 1

1.2 结构 1

1.3 材料 1

2 确定工艺方案 2

3 工艺设计与计算 3

3.1送料步距 3

3.2 条料宽度 3

3.3 材料利用率 3

3.4排样图 3

3.5 各工序凸、凹模刃口尺寸、冲裁力的计算及结构的设计 4

3.5.1冲孔 4

3.5.2落料刃口尺寸的计算 4

3.6各部分工艺计算 5

3.6.1冲裁力的计算 5

3.6.2 卸料力的计算 5

3.6.3顶件力的计算 5

3.6.4模具总压力的确定 5

3.7模具压力中心的确定 5

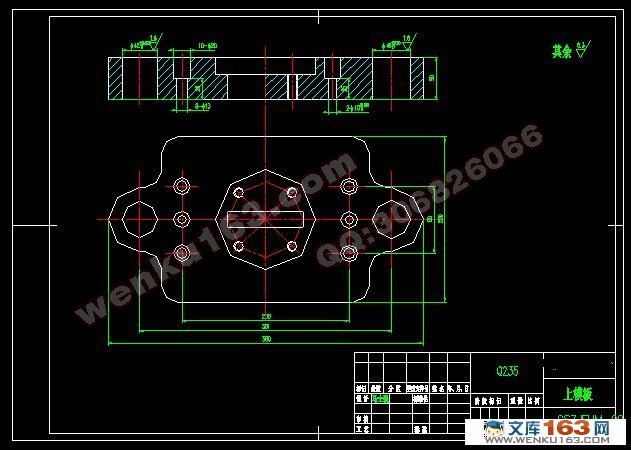

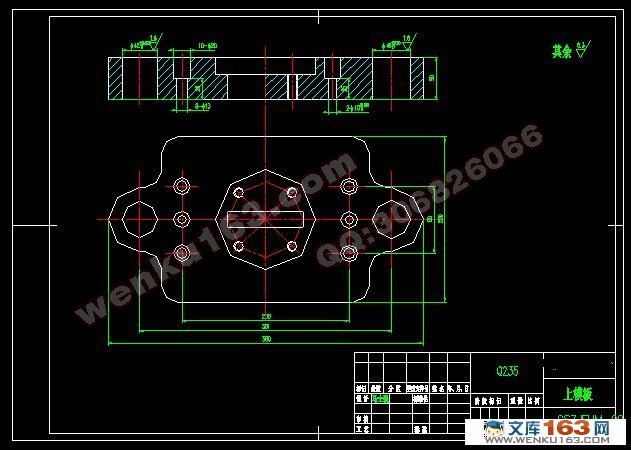

3.8 计算各主要零件的尺寸 6

3.8.1 凹模厚度 6

3.8.2 凸模固定板厚度 6

3.8.3卸料装置的采用与厚度 6

3.8.4 导料销的设计 7

3.8.5 挡料销的设计 7

3.9 模具总体设计 7

4 选定设备 9

致 谢 11 |